New technologies, distribution changes, and one-world markets are actually creating new opportunities for the professional lockshop. High-security lock discussions have traditionally focused on preventing key duplication and on defeat resistance. Larger organizations however, have learned that high-security and key control doesn’t end when the key is issued. Key control is an ongoing process that can lead to a solid business opportunity.

High Security has always been a somewhat subjective term. It may be generally agreed that pick, tamper and attack resistance, along with key duplication restrictions provide increased protection. Of course, the door, frame assembly, and surrounding access points need to offer a similar level of defeat-resistance. Improved assessment and planning tools now put the lock professional in a strong position to control his or her own destiny. A good example of the design process is Medeco’s Key System Design Studio. It helps you ask the right questions and design professional keying systems.

A strong defense against surreptitious entry and physical attack provides valuable security for your clients. Larger customers with hundreds or thousands of doors often require less complex cylinders and cores that are easier to maintain. That’s why manufacturers now offer a range of solutions allowing you to capitalize on your special skill sets. Electronic Access Control at portals and critical areas dramatically enhances accountability and works well as part of the integrated access system you design – and manage.

Since most employees don’t like paperwork, you may have the opportunity to serve this pre and post-installation key control process. You already provide ongoing key documentation for small to medium sized organizations. Larger facilities are likely to have their own internal lock shop or security office, but in many cases, they are thrilled to have competent outside help with surges or detail work. Of course, you need to be smart about pricing. Figure out a way to make it cost-effective for the client.

Key control is a term that has been often used in the locksmithing community to describe keys that are not available outside of authorized sources. In larger facilities such as educational, medical, military, and larger manufacturing facilities, the terms key control and key management also refer to the broader issue of knowing who has which keys, and what they operate. In the end, key control means not only restricting unauthorized duplication, but actually knowing when you need to change the core or cylinder.

High-security then deserves a much broader description. This includes:

- Restricted availability of keys and key blanks

- Pick and tamper resistance

- Structural integrity of the lock, door, and frame assembly, Documentation of key ownership, accountability and the ability to recover from a lost, stolen or compromised key.

- Drill resistance

- Bump resistance

And, this leads us to a little-known opportunity to profit as you serve your customers.

Increasing RMR (recurring monthly revenue) is the daily drumbeat of the burglar alarm industry, cell-phone carriers, and Amazon Prime. They all subsidize various start-up costs to get the guaranteed revenue from an extended contract. Few in the locksmithing industry have been able to leverage this business practice, but it may be there on the table waiting for you. You don’t even need to subsidize the start-up cost, or take advantage of the customer. Just solve their key loss and access control problems. Keep it simple and inexpensive, and it will grow as the value becomes apparent.

Business and institutional customers often feel that once keys are issued, they’re all done. Unfortunately, hires, discharges, promotions, re-assignments, additions, renovations and office moves add up to 20% turnover per year. Do the math. After about 5 to 8-years, they don’t know who has what keys or what key works which lock. The frequent (disastrous) solution is to issue more master keys.

A hidden profit opportunity is to issue, document, and recover the keys. If a key is compromised, lost or stolen, you recommend re-keying that door or area. This is another revenue opportunity in an ongoing win-win relationship. Effective key control spreads the cost of a major re-key over a far longer time period (I’ve seen 20-years), while radically reducing the probability of surreptitious entry from an unauthorized key.

When a key is issued, the recipient signs a key agreement promising to not dispose of, loan or copy the key (card, chip or credential). Upon completion of his or her tenure in that position, the employee agrees to return the key to the responsible key control officer, or desk. Weekly or bi-weekly onsite visits to re-key one or a few doors and to issue and recover keys, makes you an important cog in your customer’s security program. A typical one-page key control agreement is found on page 16 of ASSA ABLOY’s “Key Control Guide.” Remember to keep it simple.

Recurring monthly revenue can also be enhanced with restricted keyways. You will of course be the source for restricted keys for the smaller client. Larger organizations may have their own dedicated key – which you can also service.

Which high-security cores or cylinders should you use? The short answer is the solution that best meet the needs of you and your customer. Cost, pinning and key cutting ease, patent life, distributor stocks, key blank control, and backward compatibility to the customer’s system are issues to consider.

In the past couple of years, we’ve seen several mechanical core and cylinder developments of note. Here are a few of them.

The Pfaffenhain Germany-made ABUS Vitess™ locking system has an additional twist. In addition to the 2034 patent expiration date, the tip of the keyway actually is shaped like one of their trademarks, giving the key an additional layer of protection. This is not date sensitive, according to Abus.

The curved, paracentric key profile allows 3,000 separate keyways and prevents picking tool operation. The creative Intop notch near the key bow traps a mushroom style pin, preventing it from dropping into a lockup pocket. The tip of the key engages an additional “profile check” side pin as well. With the usual tamper and drill resistant devices, this may set a new benchmark for high-security cores.

The 0.55” Vitess cylinder allows 13 pin heights, yielding 1.5 million codes. The larger plug size currently precludes the SFIC format, although LFIC housings are now available for popular brands. Very modest stocking levels are required, and the locksmith (or owner) can order factory pinned (or pre-loaded cylinders) directly on the internet with the proper authorization. A state of the art 10,000 core per day pinning machine produces the locksmith’s order directly. Mortise cylinders, key in lever, and LFIC cores are now available.

Another development has been from the Indianapolis based Best Access division of dormakaba. The SFIC Coremax™ provides patented key protection (through May 2027) for large facilities.

The Coremax system maintains the service ease of the A2 system, adding a lug (side pin) at the rear of the cylinder, requiring the correct keyway to operate, as well as adding manipulation resistance. The system has proved popular where higher security levels are added to existing large systems. The Coremax system can be backward compatible with multiple keyways. Additional pick and tamper resistance is available as well with UL437 listed housings and cores where required. Best also offers the venerable Best Kaba Peaks® patented system.

The Kaba Peaks system is also available from the Ilco subsidiary of dormakaba at their Rocky Mount, NC facility. Peaks Preferred and Peaks Classic systems are produced and controlled by the Ilco division, for authorized security professionals. The ILCO supplied Peaks systems are available for most major brands and commercial hardware types in cylinders, plugs, LFIC, and SFIC formats.

The Schlage® division of Allegion™ uses the SL cylinder in a 7-pin housing to accommodate conventional, large and small format I/C cores. This allows larger facilities to economically integrate multiple systems under a single Everest 29™ SL system. The Primus XP version adds the lower Primus finger pins, providing additional pick resistance with maximum key duplication restrictions. Both are backward compatible with Everest B families and Everest 29 patents run to 2029. The system can be fitted to Allegion’s Falcon and many other brands.

ASSA ABLOY has become the heavy hitter in the market with their acquisition of Abloy, Arrow, Corbin Russwin, Medeco, Mul-T-Lock®, Sargent®, and Yale® product lines. The Arrow line offers an SFIC core with patented Pointe Flex system. The Pointe Flex key contains a unique tunnel that fits over a pin inside the core. The Corbin Russwin division uses the Pyramid system with a bottom trap pin and side pins in their system.

The Sargent division in New Haven, CT has three levels of their Degree® keying system. Level 1 provides a key system patented to 2027. Level 2 adds a patented side locking bar and Level 3 also includes UL437 listing. These are available in standard and LFIC configurations. Tennessee based Yale division of ASSA ABLOY offers the Yale KeyMark® with the original Security Leg® key configuration. This system is available in conventional, LFIC, and SFIC configurations.

The North American operations for the original ASSA brand are located at Medeco’s Salem, Virgina, headquarters for the U.S. and in Vaughn, ON for Canadian operations. The company offers standard and higher security Max+ cylinders with slotted twin key. The well known ASSA CLIQ system uses a key driven battery powered motor in the cylinder to rotate a small cam, allowing manual plug rotation. An excellent video demonstrates the inner workings. https://www.youtube.com/watch?v=5VA1D7_oy2A .

Medeco is the high-security division for ASSA ABLOY in the Western Hemisphere. The Salem, VA based company has produced a wide range of higher security locking devices for the past 50-years.

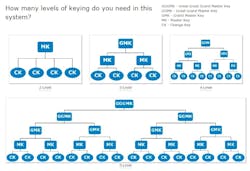

Historically, the company has concentrated on pick and tamper resistant mechanical technologies. Much of the recent development has focused on intelligent key systems and key control software. The online Key System Design Studio is an example that helps you put together a professional master key design.

https://www.medeco.com/en/site/medeco/videos/k12/key-system-design-studio11/

The company has developed a series of SFIC products from the economical MedecoB core to the Patented X4 and the electronic XT product. The X4 patent uses a proprietary slider and locking pin that provides a large number of MK options with the SFIC A2 system. This gives you access to the huge industrial, institutional, military and government markets using the SFIC core. Another little known option is the key blank with a snap-on plastic head that contains a 125KHz Prox or 13.56MHz HID iCLASS RFID chip. This low-cost option allows the key to operate Medeco mechanical locks as well as EAC protocols currently in use where the employee may not carry be carrying an access control ID card.

More on the electronic side, Medeco’s version of the CLIQ™ key is available with their own mechanical keys, complementing the flexible XT electronic key system. Both the CLIQ and the XT systems are available in multiple transmission formats, including the emerging BLE. Corvallis, OR based Cyberlock offers a complete electronic platform with the EAC technology built into the lock hardware, as well.

We’ll should also mention Amityville NY based Marks USA produces Security-Mate™ high-security cylinders, plugs, LFIC and SFIC cores using the secondary side cut to operate sidebar pins.Quebec based CX5 Security Solutions builds high-security cylinders and SFIC cores with a standard A2 pinning process. The security sidebar requires no field pinning as the side pins are factory installed for each sidebar configuration eliminating sidebar pinning labor. The patented key’s waved security groove has 60 different sidebars per keyway. The system provides a high level of pick and tamper resistance with the low labor content of traditional SFIC cores.

The good news is that the disruptive market changes are actually playing to your strengths. Distribution changes have created an opening where you can help serve larger systems. New mechanical systems allow you to service the full range of security needs while providing emergency backup stock when needed. And finally, new avenues are opening to integrate your mechanical locks with existing or planned electronic systems. Maybe there actually is a future in this business.

Cameron Sharpe, CPP wrote for Caterpillar and Honeywell before working 25-years in hardware and electronic access distribution. [email protected]

Simple Access Control Agreement

By accepting this Key, Security Code or Access Credential, I promise that I will not loan, duplicate nor allow it to be duplicated. If the Key, Code or Credential is lost or compromised, I agree to notify the Key Control Office immediately. Upon completion of my tenure in this position, I agree to return the Key or Credential to the Key Control Office or notify them of Code discontinuation before my final pay or clearance is issued. I understand that the above is a condition of employment and use of this access credential.

Signature Date

Print or Type Keyholder Name Key, Credential or User Number

About the Author

Cameron Sharpe

Cameron Sharpe, CPP, worked 30 years in the commercial lock and electronic access industry. Contact him at [email protected].