In any type of building, installing upgraded security on the entryway can present significant challenges, especially in retrofitting existing doors in occupied buildings. This task can be especially overwhelming due to the limitations of existing borehole patterns on the door, limitations imposed by the existing building, such as frame or latch construction, and/or limitations imposed by the occupants working in the building.

One of the most common limitations is the customer’s budget. Today, as there is a greater need to restrict access within a building or offices, pushbutton door hardware is becoming a popular, convenient, and cost effective solution to pricier integrated electronic access control solutions.

Pushbutton door hardware offers a convenient way to control access between restricted and non-restricted areas. There are no keys or cards to manage and inventory, no software or systems to program, and combinations can be changed in seconds at the door. Pushbutton door hardware is either mechanical or electronic in operation and many varieties are available to provide a wide range of access control needs.

Choosing the right pushbutton door hardware requires more than picking out the best deal on your supplier’s shelf. Take some time to consider usage and security needs to find the perfect fit for the customer. Pushbutton door hardware is easier to install than an integrated solution and no key is required. However, the power supply must be changed regularly and the personal identification number (PIN) must be remembered.

Pushbutton Door Hardware Options

Alarm Lock Trilogy DL2700: The Trilogy T2 is an all keyless solution, fingertip programmable, and incorporates a vandal-proof all-metal keypad. The T2 allows up to 100 unique users through 3-5 digit user codes and is powered by 5-AA batteries. The T2 is equipped with a key override.

CodeLocks CL5000: The CL5000 has a conventional 3X4 button keypad and is fully programmable at the door. It allows up to 80 unique user codes between four and six digits long. U to 10 One-Time User Codes to be entered. It is powered by 4 AA batteries.

Kaba E-Plex 5000: The 5000 Series eliminates problems and costs associated with issuing, controlling, and collecting keys and cards. It features 100 unique access codes, four to eight digits in length, and is programmable by the keypad.

Schlage CO-100: The CO-100 is ideal for doorways needing a secure, non-keyed offline solution where a credential system is not in place. The keypad-entry lock is designed for up to 500 unique users using a three- to six-digit PIN code entry only. It includes a key override as a standard feature and is powered by 4-AA batteries.

Yale InTouch: InTouch features an interactive touchcreen with voice-guided programming for simple updates to user information in the event of staffing changes or security breaches. It is programmable up to 1000 unique users, uses 4AA batteries and features a 9 volt battery connection for emergency access.

Door Prep

A great feature of pushbutton hardware is many of the models use the existing 2-1/8” bore hole that is already bored into the door. Let’s take a look at how to retrofit a cylindrical prepped entryway to receive the DL2700 by Alarm Lock using PRO-LOK’s modular Professional Installation Templates Series.

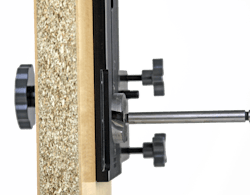

PRO-LOK’s IN-Series is specifically engineered to prep both the inside and outside of the door in one simple to use fixture and designed to significantly reduce the installation preparation time. This modular template system provides a more accurate and efficient installation because it maintains full and direct contact with the door, and uses true sized holes with hardened, heat treated bushing that already incorporate backset and bore location. These unique features help reduce installation errors and ensure fast and accurate installations.

All installation IN-Series templates are designed to work with the INCL-PRO Professional Series Universal Clamp and the concept is a modular one. Once the INCL-PRO clamp has been purchased, additional templates can be purchased at any time as needed, and use the same clamp. This system makes for fewer tools at a more economical price.

- Put on safety glasses and other protective equipment.

- Attach the INCL-PRO to the appropriate hardware specific templates for the hand of the door and specific model lock being installed. In this circumstance we will be using PRO-LOK’s IN15-PRO specifically designed for Alarm Lock Trilogy hardware. Confirm the PRO-LOK templates match the paper template included with the hardware.

- The hardware specific templates attach to the INCL-PRO with three heavy-duty Allen screws on each side.

- Attach the installation jig, consisting of the Professional Series Universal Clamp (INCL-PRO) and hardware specific installation templates (IN15-PRO), onto the door. Locate and align the installation fixture, including the INCL-PRO and hardware specific templates (IN15-PRO), off of the existing latch prep in the door. It is recommended to use a 1” auger bit to align the installation jig and the existing latch. This is critical as the hardware needs to be located properly off of the latch.

- Follow the clamping instructions that come with the INCL-PRO.

- Use twist bits, smooth bore hole saws, or plunge router, as appropriate, to create the surface holes for the operational elements required for the particular lock function being installed. The 2-1/8” bore may need to be re-drilled if it was not originally prepped correctly on the door. Always consult the manufacturer’s supplied instructions and bore the proper holes. This model has different holes for both fire-rated and non-fire rated.

- Apply the top plate attachment and finish drilling the small round surface holes. The purpose of the top plate is to give the installer accurate true sized holes with hardened, heat treated bushing for all of the holes associated with the through bolts.

- Loosen the clamping knobs and remove the installation jig from the door.

Install the lock using the manufacturer supplied fasteners and accessories. Use PRO-LOK’s flat plates or wrap plates to go between the door and the hardware to cover up any retrofit holes not in use, while giving access to the holes needed.

Being properly prepared and using the correct installation tools increases the chances for success, repeat business, and satisfied customers. Most importantly proper preparation and cost effective access control helps to ensure the integrity and continuity of the overall security plan.