In January 2021, Medeco launched its fourth-generation high-security platform, known as Medeco 4, or M4 for short. M4 meets or exceeds ANSI/BHMA A156.30 and 156.5 criteria. It also is UL 437 listed, and its patent expires in 2040.

My company has sold and serviced Medeco Biaxial and Medeco 3, or M3, platforms. We recently received our M4 inventory, parts and tools. Let’s dig into this platform and see what’s new and what’s familiar.

The M4 Design

Throughout this article, I’ll make comparisons with previous Medeco generations. As you learn about the M4 platform, you’ll understand why I make these comparisons.

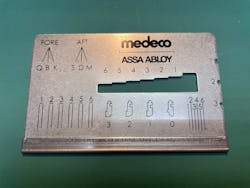

The second mechanism involves secondary cuts, or sidecuts. M4 keys feature four finger pins for six-pin blanks (three for five-pin blanks), which have three possible depths. Among the sidecuts is a permanently retained, stainless steel key movable element (ME), which protects against 3D-printed copies of the key. Much like the M3 slider, these sidecuts are cut at the factory and assigned to a specific keyway. If you’re familiar with Schlage Primus or ASSA Twin, the M4 key is similar to both.

The M4 sidebar can retract into the plug only after the primary and secondary pins are lifted or rotated into the correct position. If you’re familiar with Medeco platforms, then you likely have deduced that because of the introductions of sidecuts, a new sidebar design would be necessary. That deduction is correct.

As you might have noticed by now, M4 shares a lot in common with its predecessors: Biaxial and M3. All three platforms use the same bottom, master and top pins, as well as the same spacing and depths. This means that with the appropriate jaw or jaw accessory, key machines capable of cutting Biaxial and M3 keys also will be capable of cutting M4 keys, which I will touch on later.

Keying and Masterkeying

The M4 design provides the largest number of theoretical keying capacities of any mechanical Medeco platform, which is great news for those of us who supply Medeco products for masterkey systems. M4 cylinders and keys offer 10 possible positions (six primary cuts plus four secondary cuts), which allows for 9 million theoretical combinations in a two-level masterkey system. For comparison, this number is 1 million for Biaxial cylinders under the same criteria and 6 million for M3.

The number of theoreticals can be increased through mastered finger pins, which allow cylinders to accommodate keys that use different sidecuts. As with Biaxial and M3 platforms, the M4 platform also is capable of using “double cuts” to expand masterkeying capabilities significantly.

Except for complex systems that use different sidecuts, you can use any masterkeying software for the M4 platform that’s capable of generating systems for the Biaxial and M3 platforms.

Servicing

As mentioned, M4 uses the same bottom, master and top pins as Biaxial and M3. If you already are equipped to pin either Biaxial or M3, you’re equipped to pin M4. Much like M3 with its slider, M4 is shipped with the finger pins preloaded, so you won’t have to bother with anything beyond the primary pins, springs and caps unless you build highly complex masterkey systems. (You can order cylinders that don’t have finger pins installed if you’re so inclined.)

If you have to service the finger pins, however, the process is relatively easy and covered in detail in the Medeco 4 Technical Information Manual. This manual is free for locksmiths who sell Medeco products and worth obtaining!

Medeco offers a pin kit that will provide you with all available finger pins and springs. From one professional to another, you should buy this kit, because it comes with an M4 decoder. That decoder is worth the price of admission.Cutting Keys

Medeco offers an M4 quick-change vise jaw that allows locksmiths to cut M4 keys by using their existing Medeco Biaxial/M3 key machines. Although we use ITL 9700s to cut our Medeco keys, which can cut M4 keys, I purchased a quick-change jaw as a backup.

Speaking of aftermarket key machines, several also are capable of cutting M4 keys through the purchase of a new jaw from the manufacturer. Key machines that can accomplish this include the Framon KX-1 and HPC Blitz, CodeMax and Tiger SHARK2.

It’s important to note that by the time you read this article, the Bilevel version of M4 should be available. Later in 2022, M4 also will be available in CLIQ electromechanical and cam and industrial lock formats.

Conclusion

My company is a Black-level Medeco dealer, which means we service and sell a large amount of Medeco products throughout the year. There always is a bit of concern when a high-security product that you sell a lot of nears its patent expiration date, as was the case with M3.

The biggest concern is as follows: What will it take for us to offer the next generation? I don’t mean a “buy-in,” although that can be a factor, but more what will we have to change? Will we have to buy new machines and new pinning kits, both of which will require additional office space? Will we have to learn an entirely new approach to masterkey design or rules?

The good news is I safely can say that Medeco has assuaged these concerns with the M4 platform. We don’t have to put another pin kit on the bench. We don’t have to buy another key machine. We don’t have to reinvent our masterkey software or learn new rules.

Medeco has found a way to provide locksmiths who sell Medeco with a patented product for at least the next 20 years that requires little investment or changes to the way they do business. Will that be the case for the company’s fifth-generation platform when the time comes? I don’t know, but I know that for the next 20 years, I can offer a patented high-security platform that requires almost no change to how my company has done business for the past 40. For that, I’m highly thankful.

Tyler J. Thomas, CJIL, CMKA, CRL is vice president of Security Engineering Consultants in Atlanta and is the Southeast director for ALOA.

About the Author

Tyler J. Thomas

Tyler J. Thomas, CJIL, CMKA, CRL is the president of Security Engineering Consultants in Atlanta, where he and the company specialize in high-security masterkey systems. He is the current Southeast Director for ALOA Security Professionals Association, a position he has held since 2019, and an active member of the Lock Industry Standards and Training (LIST) Council, as well as an administrator for Locksmith Nation, the world’s largest online locksmith community. Tyler is also an active member of the Locksmith Security Association (LSA) of Michigan and was the first official member of LSA who resided outside of the state of Michigan. Outside of locksmithing, Tyler enjoys gardening and spending time with his wife and their three kids.