Storefront Security with Ilco 452 Series Heavy Duty Deadlatch

Glass and aluminum construction brings the outside in through the glass walls and doors, offering a more welcoming appearance and maintaining energy efficiency for many commercial establishments, multi-family housing and office buildings.

For swinging glass aluminum stile doors, the framework is extruded aluminum in varying widths with a large glass panel. Common stile widths are narrow, medium and wide. Although different manufacturers’ widths can vary, rough sizes are 2" narrow, 3-1/2" medium and 5" wide. These measurements are for the outer extrusion only; it does not include the portion of the stile that retains the glass. Regardless of the different widths, aluminum stile lock hardware can be used in most doors.

Key-operated mortise lock choices are the deadlatch and the pivoting deadlock. The deadlatch provides controllable access, requiring a key from the exterior or, if configured, using an operating key to retract the latchbolt and placing the lock temporary in passage mode. Any operating key can place the deadlatch in passage mode or release the lock from passage mode. Pressing an exit device, paddle or rotating a lever provides egress. The deadlock, which is actually a pivoting deadbolt, is normally used during non-business hours to provide an extra level of security.

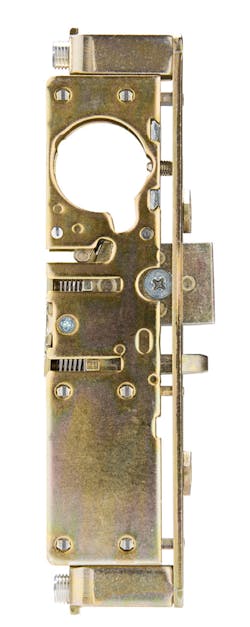

Ilco has been offering locks and exit device hardware for storefront doors for a number of years. The 452 Series Heavy Duty Deadlatch meets or exceeds ANSI/BHMA Type E8231 requirements for a Grade 1 deadlatch. The case is manufactured from corrosion resistant plated steel. The 452 Series Deadlatch has a 1-1/2" long by 5/8" wide latchbolt that has a ½" throw. The deadlatch is field reversible and does not require lock disassembly. The non-handed auxiliary bolt prevents "loiding" including latchbolt manipulation.

The 452 Series Deadlatch comes standard 1-1/8" backset, accepting a 1-5/32" diameter Ilco or compatible mortise cylinder with a number two cam for keyed operation from the exterior. Ilco offers four strike options: flat standard jamb, radiused/standard stile and flat/center hung 4" or 4.5" jamb. The 452 Series is interchangeable with the Ilco 451 Series Deadlatch and the 185 Series Deadlocks amd compatible with most aluminum stile door locks. Its overall dimensions are 6.815" tall by 1.78" deep by 1" wide at the face (.898" wide at the back of the case).

The Ilco 452 Series Deadlatch door prep has a 6.89" tall by 1.010" wide opening with a .156" radius. The cross bore centerline opening for the mortise cylinder, etc., is 1.6" beneath the top of the edge bore opening. This is the standard door prep for a 1-1/8" backset deadlatch.

Features of this new deadlatch include exit only free egress, the ability to change handing without disassembling the deadlatch, and ability to accommodate beveled, radiused and flat stiles and depth tube spacer assemblies.

The 452 Series latchbolt cannot be placed in the retracted position by a reverse turn of the key. The lock is always locked. This style of deadlatch is used in common entries where you would not want a person with the key able to unlock the lock and put it into passage mode.

To change handing, remove the screw securing the latchbolt. Slide out the latchbolt and reverse it, placing it back onto the spring-loaded mechanism. Insert, thread and tighten the screw.

Aluminum glass storefront doors lock stiles have four lock edge configurations: radius, flat and beveled (left or right hand). The Ilco 452 Deadlatch has a bevel adjustment using the two bevel tabs, which are surface angled metal squares with an arrow stamped into the thin edge. For beveled stiles, rotate the tabs in the direction of the bevel. For radiused and flat stiles, rotate the tabs having the arrow point up or down. The flat faceplate is used for the beveled applications.

The 452 Series Deadlatch is equipped with depth adjusting tube spacer assemblies that allow for a quick and precise installation. Many of the storefront door lock companies that sell assembled doors make use of these assemblies as the installation time is reduced as the two mounting screws are installed into the holes that have been drilled and tapped at the back of the door frame (channel).

These depth tube spacer assemblies are mounted onto the case front with the threaded aluminum tube extending from the rear. The tube is adjusted to position the lock case within the stile where the installed faceplate will be flush with the edge of the stile. The depth adjusting threaded tubes contact the inside of the stile channel. With the lock placed within the stile, use a 3/16" hex wrench to make the fine adjustments. Install the two supplied mounting screws and the appropriate faceplate. These two depth adjusting mechanisms take the place of mounting brackets.

The Ilco 452 Series Deadlatch is available as lock only; lock with one or two faceplates and/or with strikes.

For more information, contact your local locksmith distributor or Kaba Ilco, 400 Jeffreys Road, Rocky Mount, NC 27804. Telephone: 252-446-3321. Web Site: www.ilco.us

About the Author