Back Page, May 2025

10 Years Ago

Jerry Levine installed a concealed vertical rod exit device from Command Access Technology. Levine also looked at mechanical and electromechanical locks for narrowstile aluminum glass doors. Also on the storefront side of things, Tim O’Leary reported on storefront solutions for challenging environments. O’Leary also highlighted the newest keypads and readers on the market in 2015, including HID mobile access, the Securitron R100-1H wireless reader and the Farpointe P-640 Patagonia dual-credential reader. The STRATTEC Bolt line of rekeyable padlocks and the CCL 450 weather-resistant line were featured in Gale Johnson’s article “Spring into Padlock Sales.” Medeco introduced the Protector II high-security padlock. Andy Miller from Turn 10 wrote about the difficulties U.S. safe sellers face when competing against overseas online safe sellers, still an issue today. D&D Technology’s SureClose ReadyFit gate closer/hinge combo was suggested as a code-compliant pool gate solution. Articles in our May 2015 Automotive Supplement included “Harvesting Transponder Chips,” “Reshelling Ford Integrated Keys” and “Servicing the Ford Transit Connect.”

20 Years Ago

Electronic access control was the topic for the month. Cansec reported on their Zodiac Lite biometric system. A special report showed how to have a forklift operate an automatic door opener. Jerry Levine installed an electrified Sargent exit device. Tim O’Leary reviewed a Kaba Power Lever Prox 9000. Levine tested a Codelocks CL5000 lockset. A history of Chrysler double-sided automotive locks was presented. Tom Gillespie looked at various auto lockout tools. Steve Young showed ways to unlock vehicles which have power door locks. Schlage wrote a success story on securing a North Carolina hospital. Billy Edwards showed the new Master Fusion lock product group. Gale Johnson repaired an antique bit lock. Levine programmed a 2005 Chevrolet Malibu transponder key. Tiny showed how to service Chevrolet Cobalt locks. Locksmith Ledger printed an interesting interview with Tom Demont.

Setting up a Keyboard

Editor’s Note: Though the number of key blanks has probably expanded in the past 10 years and some of the manufacturers have changed, setting up an efficient keyboard remains a challenge for commercial locksmiths.

The keyboard has long been the life's blood for a locksmith shop and service vehicle. Providing easy access, visual stock status and the ability to expand, the keyboard lets locksmiths know key sales direction instantly.

There are upwards of 7,000 different key blanks. This includes commercial, residential, utilities and vehicular key blanks. Most locksmiths maintain a stock of 1,000 or less different key blanks. Even a thousand key blanks presents a significant challenge to have each number easily available for duplication or origination.

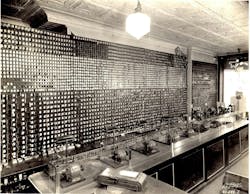

Locksmith shops seen in photographs from the early 1900s show key blanks organized on the store walls. Generally, the key blank boards are mounted onto the exterior walls; starting at about waist height and going upwards. The black and white photo is one of the S & S Locksmith's keyboards, measuring 24 feet long and eight feet tall. According to the grandson of the owner, more than 400,000 key blanks were on this board when fully populated.

There are many different ways to populate keyboards. The most common start appears to be separating automotive key blanks, safe deposit key blanks and specialty key blanks such as keys designed for safe locks, luggage, bit and barrel and flat steel from the cylinder key blanks. When I set up keyboards, I combine the North American and the International Cylinder key blanks as they are all cylinder key blanks.

Once the key blanks' categories have been separated, the next step is to determine how to organize them. There are several ways including alphabetically by manufacturer or using an aftermarket key blank manufacturer’s numbering system.

Read the full article at https://www.locksmithledger.com/keys-tools/article/12059913/keyboards