Back Page, October 2021

10 Years Ago

Chris Clark from Ingersoll Rand (now Allegion) wrote a guide to Conducting Fire Door Assembly Inspections. A second article on fire-door inspections provided training options for locksmiths. Two additional articles addressed 2011 code issues. Jerry Levine installed an Arrow DC500 Series surface-mounted door closer. Steve Young’s article, “What’s New in Vehicle Entry,” discussed which car-opening tool to use. These days, it’s all about electronics. Another automotive-themed article recommended using the Ilco 057 HS Key Machine for high-security automotive keys. An early version of the doorbell camera, MAS Intercom’s analog doorphone that has remote monitoring was featured. Gale Johnson provided a historical perspective of Corbin Russwin. Rod Oden’s article, “Conducting A Site Survey: Points to Consider,” advised locksmiths to start with identifying the doors, the lock and door hardware by brand, type, keyway and number of lock cylinders.

20 Years Ago

Dick Zunkel looked at hardware that’s available for sliding doors. Tim O’Leary showed the Arrow IC Choice products. Jerry Levine installed a SARGENT electronic lock that had an optional keypad or proximity/keypad feature. Chuck Havill, IR Security and Safety Sector, suggested possible growth opportunities for locksmiths. WearGuard presented suggestions on work wear garments for locksmiths. An article by Jerry Levine showed the installation of a Locknetics cabinet lock system. Tom Gillespie installed a B52 safe lock by Mas-Hamilton. VATS was the topic of an article about keys available from Howard Keys. Tiny showed how to fit keys to a 2000 Subaru Outback. Major safe manufacturer Mosler announced that it ceased operations as of Aug. 3.

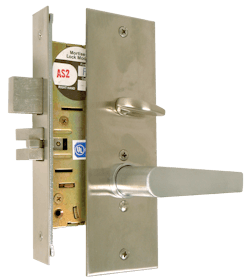

Servicing and Retrofitting Mortise Locks

Servicing a mortise lock is relatively easy, because the body can be removed from the door and disassembled without manipulating the lock cylinder.

The first thing I do when servicing or repairing any lock is look at the door and the jamb, checking the gap. I then look at the floor to see whether there’s any evidence of dragging. I check to see whether the door operates and the door closer, if equipped, is able to close the door and latch the lock.

After I’m satisfied the door and jamb are in operating condition, I lightly lubricate the mortise cylinder keyway to make sure a key operates smoothly. Then, I carefully operate the lock with the door open and closed. If the problem occurs only when the door is closed, I check the door or strike alignment. If the problem discussed can be repeated, the solution can be determined.

After you have a general idea of the problem, then you should remove the mortise lock body from the door. Behind the front, two setscrews secure the mortise cylinders or the inside thumbturn. Loosening the setscrews permits the mortise cylinder and thumbturn to be unscrewed. The interior knob or lever either has a setscrew or a threaded sleeve that must be loosened to remove the interior and exterior knobs or levers. If the mortise lock is through-bolted, there usually is a spring cage on the interior side that must be removed to remove the exterior lever and spring cage. Older mortise locks can be equipped with a handleset. The handleset is removed typically by unscrewing the mounting screws on the interior side.

After the levers, handleset or knobs and the mortise cylinder(s) and thumbturn (if equipped) are removed, unscrew the two edge mounting screws and slide the lock body out of the door.

Always research the lock you service before the job. Manufacturers’ information can make the service straightforward and easy. Some mortise locks require specialized tools.

Read the full article at https://locksmithledger.com/10344085.