Choosing the Right Power Supply to Avoid Access Control Issues

Unlike camera system power requirements, access control systems draw more current for locking hardware and during access control-related events. As the industry transitions from solenoid-based electric locking devices to motorized devices, demand for specific power supply requirements has also increased.

The following summarizes a three-part series on Access Control Power that appeared in the October through December issues of Locksmith Ledger magazine in 2020. Those articles detailed why power supply requirements are different for electronic access control (EAC) hardware vs other devices or fire and life safety systems, and that one size does not fit all.

Types of Power Supplies

Switching Power Supplies

Switching Power Supplies are typically designed for use with resistive or capacitive loads such as low voltage lamps, alarm panels, cameras and signaling devices. They are lighter in weight, efficient (less heat generated) and are cheaper to manufacture. The low price of switching power supplies often encourages their misapplication.

Switching power supplies are not recommended for use with access controls and electric locks for several reasons. Typical switching power supplies have trouble handling the inductive loads produced by locking devices with coils or solenoids due to the limited current reserve available to handle periods of high inrush. Excessive current draw (even for a short period of time) will briefly stop a switching supply from operating and may even permanently damage it.

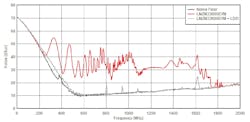

Another byproduct of the switching power supply is a high frequency noise component that appears in the DC voltage output. A properly designed supply includes a filter circuit to reduce or eliminate this noise. Many switching power supplies do not include more effective output filtering due to cost constraints. The filter part of the supply can cost as much as the regulator circuit so a good high frequency filter is often left out. Although the noise will not harm a simple device like an electric strike, the noise may cause erratic operation of electronic equipment such as access controls, electronically controlled locks, panic bars and door controllers, causing them to malfunction and may even damage these units.

These “low cost” switching supplies often require that you supply your own power transformer and assemble these two components in your own box. The result will be a NON-UL listed power supply allowing an opportunity for local inspectors to not approve an installation.

Linear Power Supplies

Linear Power supplies have been used for years for powering resistive, capacitive and inductive loads (devices with coils or solenoids, such as electromechanical and electromagnetic locks and strikes) due to their ability to handle large inrush currents. Since most of the DC filtering is done with large filter capacitors, there is plenty of reserve power and they can provide extra current for short periods of time without malfunction or damage. The output is also free of high frequency noise found in switching power supplies making them practical for use with access controls.

However, the penalty in using a linear power supply is the heat generated by the regulator component of the supply due to its moderate efficiency. The heat generated can lead to early failure of the temperature sensitive components housed near the supply board.

Hybrid Power Supplies

Hybrid Access Control Power Supplies are ideal for powering resistive, capacitive and inductive loads – the type of unique power loads common to access control locking devices. Hybrid power supplies combine the efficiency (low heat generation) of a switching supply and the rugged inductive load capability of a linear power supply.

This can be accomplished by adding extra filtering to the output stage of the power supply to provide clean noise free power for access controls and enough current reserve is available to reliably power inductive loads. Including built-in inductive kickback protection will enable high inrush protection caused by electric lock solenoids and motors. This type of hybrid power supply is a good overall choice for powering all access control system components.

How to Avoid Problems

EAC Power Issues

Based on more than 50 years of manufacturing electronic access and egress control solutions, including locking hardware and power supplies, we have quantified that at least 75 - 85% of access control operating problems and technical support calls are due to power issues,* resulting in:

• Dead Systems

• Malfunctioning Locks or intermittent operation of Accessories, Controllers

• Locking Devices that won’t respond reliably

* SDC Technical Support Logs

Why? Because EAC power requirements are different from systems like CCTV for example. These issues can be eliminated by following best practices for power design and installation protocols specific to electrified access control hardware including:

• Access Control Systems require steady low-voltage DC current

• Access Control Systems generally draw higher current during access control-related events - readers, shunt and strike relays, door locking devices, gate operators, controllers and annunciators

Before selecting a power supply, we recommend you plan now to avoid trouble later. This means you should carefully evaluate your project to avoid common installation and operating problems.

• Understand the power required and know the power available (if retrofitting)

• If retrofitting, what modifications have been done over the years affecting the capacity of the power supply?

• Power supplies wear out. If more than 10 years old, replace it

• Do all the products really work together? Take responsibility

• Code Compliance - be aware of applicable regional and national codes

• UL 294 – become familiar with this access control standard. Find out if your AHJ requires the installation to be UL 294 compliant, and get your AHJ involved in your system design

• Battery Backup Calculations – how long must the system function after power loss?

• Low Voltage license - is one required in your jurisdiction?

• Don’t cheap out on recommending a quality system design

• Plan not to come back, do it right the first time

• Plan for future expansion - no one has ever needed less power for their facility’s access control system. Requirements change over time

Low Voltage Power

With few exceptions, talking about Access Control Power concerns low-voltage, 12 or 24-volt DC power for most Access Control Systems. Unlike security camera/video systems typically deployed throughout a facility, Access Control locking hardware draws more current, especially during an access control event - such as the locking or unlocking of a device. Providing steady, low-voltage DC current requires a power supply to convert incoming AC voltage to DC.

Calculating Current Load

Before selecting power supplies for your access control system, you must calculate the power load (current) required for each door opening. Use a Door Checklist like this example to fill in values and calculate the current load:

• Locking Device (_____ Amps)

• Rex Button (_____ Amps)

• Control Panel (_____ Amps)

• In/Out Readers (_____ Amps)

• Annunciator (_____ Amps)

• Total: (_____ Amps)

Next, add a 30% safety margin. Combine these values for an overall system total, as well as subtotals per floor or building. This will help you to:

• Determine what size power supply is needed

• Select and locate the appropriate power supply components

• Determine wire gauge requirements based on load, cable distance and voltage drop

Voltage Drop

Power supply voltage will drop over long cable distances due to wire resistance. Operating access control devices with inadequate or excess voltage makes them run hotter, wear out faster, operate erratically or not at all. A good rule of thumb for access control devices is that voltage drop cannot exceed 5% of the supply voltage. There are many free voltage drop calculators available on the internet to obtain a voltage drop calculation by simply entering the wire gauge, voltage, distance and load current (Amps).

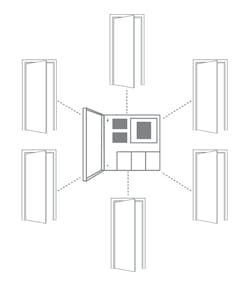

Centralized Power

Before proceeding, you’ll need to consider what type of power system - Centralized or Distributed - is best for your installation as it will greatly affect your Voltage Drop calculations. If your project involves multiple doors, there are pros and cons to using one large - Centralized - power supply to meet the system requirements. The pros and cons of centralized power deployment are:

PROS

• Supplies are protected from vandalism

• Single location for fire system interface

• Easier to monitor/maintain power system

• Lower cost per door (based on cable distance, labor costs)

CONS

• Single point of system-wide failure (especially when using one large supply)

• Difficult to reconfigure for system expansion

• Longer, heavier cabling required for home runs with centralized power

Distributed Power

Distributed Power refers to using a power supply for each door.

The pros and cons of centralized power deployment are:

PROS

• Adequate power will be provided for each new door

• Easier to accommodate system expansion

• Shorter, lighter gauge cabling can be used

CONS

• Higher cost per door

The point can be made that it is also easier to service everything at the point of failure in a Distributed Power system.

Dual Voltage Ouput

Dual Voltage Output is frequently required when powering access control panels at 12VDC and door locking devices at 24VDC. Look for 12/24VDC linear power supplies with various current output capabilities and/or add-in 12VDC regulator modules to provide output for access controllers, readers, or other devices.

What Else to Look For In a Power Supply

Much of the selection criteria for a power supply depends on your specific project application. However, there are some features worth recommending:

• Field selectable 12 or 24VDC, regulated and filtered

• Auto resetting output circuit protection

• Backup battery with isolated battery charger

• Low battery disconnect

• Emergency release input (also the fire alarm input)

• Input, output and battery status LED’s

The quality and reliability of electrified hardware brands in today’s industry is very high. And unless it was improperly installed or damaged during installation on your project, the device is probably going to reliably operate for years to come. However, if you don’t add consideration of power and the power supply, you may be headed for trouble down the road.

Don’t forget, industry associations like ALOA (www.aloa. org), ESA (www.esaweb.org) and others, have a wealth of information, tools and training to assist you in your electrified door hardware and access control projects.

About the Author

Kerby Lecka

Director of Marketing, SDC

Kerby Lecka is marketing director at SDC – Security Door Controls. He can be reached at [email protected].