Volumes have been written and various training courses designed to educate security pros about the proper ways to convert door openings to electronic access control (EAC). This overview is a short summary of recommendations to consider when upgrading any door from mechanical to electronic.

Before doing anything, you have to determine the access control objective for the door, which falls into three main categories: security, life safety and accessibility.

Security considerations include risk and asset management, personal protection and crime prevention. Life-safety requirements cover fire, crisis management, crowd control, senior and infant protection, and hazardous material or disease control. Accessibility concerns human and vehicle traffic control, the actual building function and Americans with Disabilities Act (ADA) compliance.

With an understanding of EAC objectives, you can identify the full potential for the upgrade. Will your solution have to integrate with other technologies to maximize the benefit? Is there an opportunity for customer revenue beyond this door from options and upselling? Is this project right for you?

Application Considerations

Identifying the best suited EAC hardware requires a review of many factors.

Know and understand the products you install. Make sure you’ve identified the code-compliance requirements specific to the EAC hardware and supply them to your customer. This includes any performance certifications (ANSI/BHMA), lab listings (UL) and product or service warranties. This information might be a deterrent to having an inspector reject the installation today or at a later date when code changes take effect. In addition, noncompliant components could lead to potential liability in the event of a fire or life-safety emergency.

Use a door checklist for each opening.

If you don’t already use some sort of door-assessment checklist, we recommend you start with any trade association or EAC manufacturer you deal with as a resource. (SDC has developed a comprehensive Door Checklist in interactive and downloadable versions.)

A door checklist will help you to capture key door details that will figure into the proper application and installation of an EAC component upgrade. Door handing, type and size of the door, and type of door header and frame are important to confirm, as well as existing lock, hinge, door closer (if any), ceiling type and height and distance from the power supply.

Evaluate the opening’s condition.

While you fill out your door checklist, it’s important to note the condition of the door. Does it close properly without binding or rubbing? Does it positively center? What environment and conditions does the door operate in? If there are issues, they’ll have to be resolved before installing the EAC upgrade.

Identify existing hardware.

What’s the current door hardware function — storeroom, classroom, entry or passage? Can existing hardware, such as a mechanical exit device, be modified for electric operation or will it have to be replaced to operate in an EAC system? Is a field electrification kit available? If you add an auxiliary electrified lock, will it integrate with existing hardware, such as an electric strike or maglock? Is a factory-installed modification required to maintain a UL listing?

Determine fire-rated requirements.

Fire-rated openings are common in stairwell and elevator lobby door situations and must meet be code-compliant and approved by the Authority Having Jurisdiction (AHJ). Some key requirements:

- Code requires self-closing and latching equipment.

- Free egress is critical for life safety.

- Fail-safe electrified hardware is mandated.

- Modifications to install hardware might require recertification of the door or frame.

- Electrified hardware typically is tied into the fire system to release in the event of fire, power failure or other emergency.

Identify the EAC Solution

In the old days, doors were unlocked manually during business hours, or staff employees were given a key to a door or facility. One way to provide EAC now is by installing a keypad or reader at the door to control who can gain access by entering a PIN code, swiping or placing a credential near to the reader or using a smartphone. Keypads and readers come in stand-alone models or have outputs to connect them with an enterprise system and typically release some type of electric door lock to gain entry.

Battery-powered stand-alone electric locksets can be combined with keypads and readers that don’t require hard-wiring to an EAC system in cylindrical, mortise or rim exit device configurations, as well as Bluetooth and Wi-Fi-enabled models.

For applications such as a roll-up door or automatic gate, wall-mounted key switches may be used to control access instead of keypads and readers.

An important factor is whether the door must conform with ADA requirements. ADA is intended to guarantee equality for those who have disabilities. Title III of the law covers Public Accommodations and is a directive to ensure accessibility within public buildings. Retail storefronts, office buildings, campuses and healthcare facilities typically have to meet ADA requirements at points of access and egress.

Low-energy automatic door operators can be used to maximize public door accessibility for ADA applications. ADA-compliant door-opener actuators, such as wireless and hard-wired push plate switches, can be used for handicap access and request-to-exit (REX) applications.

Some are wall-mounted, while others are placed within bollard posts at the entry or exit to the door. The popularity of touchless exit switches to control automatic doors for a hands-free experience has increased dramatically as a means to increase public health and safety in the wake of the COVID pandemic.

The Right Lock

Locks all provide security, but not all are suitable for every door.

Electric strikes enable the electrical release of a locked mechanical latch or bolt and are well-suited to new and retrofit applications. Electric strikes are available in a variety of configurations to accommodate several types of mechanical locksets and door and frame styles, as well as fail-safe and fail-secure applications.

Electrified cylindrical or mortise locksets are used to meet building and fire life-safety codes for fire-rated office doors, corridor doors, lobby doors, exit doors and stairwell doors. Whether fail-safe or fail-secure, controlled access and remote-control capability is provided while the door stays latched even when unlocked, which maintains the integrity of a fire door.

Unlike electric strikes, electric bolt locks require no other mechanical lock device to provide security. Electromechanical bolt locks are available in fail-safe and fail-secure modes. Applications include high-security interior doors and cabinets where maglocks aren’t required.

Powering the EAC

Hardware-control and door-control modules are offered by many manufacturers to control separate electrified locking devices, multiple doors, relay operating and system modes for lock control, monitoring, communicating door and lock system logic. They typically are installed in the power supply cabinet and provide a centralized wiring location, simplify installation and make for easy troubleshooting.

Power-transfer devices are required to power EAC components and include power-transfer loops, concealed power-transfer hinges and devices.

Not to be forgotten is the power supply itself. Security pros should know that power requirements for EAC hardware are different from other systems, such as CCTV. EAC systems require steady low-voltage direct current. EAC systems generally draw higher current during access control-related events, such as when an electric strike is released.

Before selecting a power supply, plan ahead. This means you should evaluate your project carefully to avoid common installation and operating problems. Consider the following questions:

- What power is required and what power is available (if retrofitting)?

- lf retrofitting, what modifications have been made over the years to affect the capacity of the power supply?

- How old is the power supply? If it’s more than 10 years old, replace it.

- Do all products really work together?

- What regional and national codes might be applicable?

- Does your AHJ require the installation to be compliant with UL 294, which is an EAC standard? Get the AHJ involved in your system design.

- How long must the system function after a power loss?

- ls a low-voltage license required in your jurisdiction?

What About Egress?

Key-switch assemblies provide an economical method of controlling a variety of applications at the door. Most assemblies use U.S.-standard 1-inch or 1-3/8-inch mortise-key and interchangeable-core cylinders to maintain compatibility with a new or existing mechanical key system.

Many manufacturers also provide a variety of push-button styles and contact configurations to fit several REX application requirements. Wave-to-open switches and motion sensors provide hands-free compliance and convenience for touchless applications through the use of proven infrared-detection technology.

Egress devices are designed for the release of maglocks and the activation of delayed-egress locks installed on nonlatching doors. REX push bars provide uninhibited egress through access-controlled openings equipped with maglocks, which enables egress by a single natural motion.

Exit devices are an essential hardware component found in almost every building for safety and security. Electrified exit devices allow for more control of the opening and can interface with other electronic equipment. They can control the latch bolt of a device or the locking of the operating trim.

The electric locking and unlocking of the exit device is controlled in one of two ways. Through electric latch retraction (ELR), a solenoid or motor retracts the latch and holds it in the “dogged” position until power is interrupted. The door operates in a push-pull manner.

The second method controls the operating trim, which allows the exit device to remain latched. The exterior level, knob or thumbpiece is electrically locked or unlocked for entry control in either fail-safe or fail-secure mode.

Electrified exit device manufacturers offer a variety of available trim options: rim mount, surface vertical-rod and concealed vertical-rod device types. Panic and fire exit device solutions are available for virtually any door opening application. Cost-saving modification kits can convert existing mechanical exit devices to electronic in the field.

Features and Functions

That said, remote controls and annunciators are designed to meet the demands of different control and monitoring applications without computer-based EAC capability. They provide methods for central monitoring and control of openings in a facility as well as audible or visual status supervision and notification. They can include desktop modules that have switches to release a single opening and LED displays to indicate door position or lock status.

LED displays also can be placed at the door opening to provide visual status of the door. Door prop alarms that have timed delay, LED status display and buzzer alarms are available to prevent the piggybacking of unauthorized people through a controlled door opening.

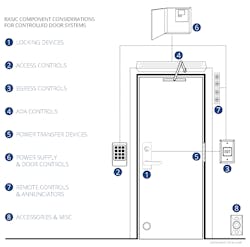

Plus, a variety of electrified accessories and specialty items can enhance any EAC conversion solution, depending on the application. (See “Basic Component Considerations” for a summary of product recommendations to consider when upgrading any door from mechanical to electronic.)

Hopefully, this article has provided practical insights for consideration when assessing a door for an EAC retrofit that will help to minimize liability and maximize the profit potential for the installation. Industry associations, such as ALOA (www.aloa.org) and ESA (www.esaweb.org), have a wealth of information, tools and training to assist you in your electrified door hardware and EAC projects.

Kerby Lecka is marketing director at SDC – Security Door Controls, a manufacturer of premium-grade EAC hardware. He can be reached at [email protected].

About the Author

Kerby Lecka

Director of Marketing, SDC

Kerby Lecka is marketing director at SDC – Security Door Controls. He can be reached at [email protected].