Tech Tips: Electromagnetic Lock Release Requirements

Are keys and keyswitches an anachronism in modern age locksmithing and access control?

After all, the marketing push is the elimination of keys in favor of other methods of security and authentication. Besides the industry’s and the end-users’ insatiable appetite for “new and improved” products, it did reach a point some time ago where it was apparent that the role of the key in security was going to change.

Among many other things, keyless cars, unscrupulous scammers, key bumping and key vending machines contributed to the decline of the key’s reign in security.

My own entry point into the security industry was not as a locksmith; but rather from the other end of the spectrum, as a purveyor of the first and most famous electronic keyless entry system (which dominated the market for decades until new technologies caught up then overcame it in the marketplace). Our clients were primarily locksmiths whose customers demanded keyless entry alternatives. Most of these locksmiths are still doing very well as locksmiths, which indicates that there are many roles for the locksmith to fill in security without abandoning their craft.

There are shortcomings with keys; but there are shortcomings with any technology, so pointing out the problems is not to say these problems are not present with other technologies.

- Convenience: An argument used against keys is that you have to have the key in your possession in order to use it, and folks are prone to forget their keys.

- Security: Many keyways are available over the counter from a growing number of sources, including retailers. Many keys can be readily duplicated in a growing number of locations, including vending machines, and there is no way to know how many copies of a key exist.

- Authentication: Having possession of a key does not prove the person having the key is authorized to have the key.

Therefore if you supply access control to an opening, and there are keyed locks or keyed overrides on any other exterior doors of the premises, the safety of the site is measured by the weakest link. In this case, that would be any non-patented and not pick resistant cylinder on another exterior door.

We think that a key override is essential for electronic access control, but it has to be done correctly to provide the anticipated level of security.

Additionally, we recommend multiple security technologies be integrated into every project where security is a real concern.

The fewer doors with a cylinder override the better, and the keys of the cylinder must be strictly controlled, for example one key with the owner and one key locked in a safe off site.

Your locking system must conform with the building code as it applies to your municipality and the type of occupancy and opening. It’s advisable to submit your plans to the Authority Having Jurisdiction (AHJ) first for approval before spending the client’s deposit or buying components. The AHJ has the final approval of the system, so best to get some feedback from him first.

Building Codes are typically based on a model code and NFPA codes such as NFPA 80 and NFPA 101. These codes are under constant revision, and you would need to find out what revision is being observed in your area.

Sometimes an AHJ may have his or her own thoughts on a particular part of the code, and that’s their prerogative. Also you may have an additional AHJ to deal with if there is any line voltage wiring involved.

AHJs may scrutinize the following components in your access control system:

- The Design and Theory of Operation of the system

- The life safety characteristics of the system and its proposed interface with the premises fire alarm

- Firewalls that could be penetrated while wiring is installed.

- Appropriate licensing of you and any others doing the work

Many times the fire marshal will do a walk through concurrent with an annual or semi-annual inspection. This is not the best arrangement if you put the system on line and then need to make revisions after getting approval.

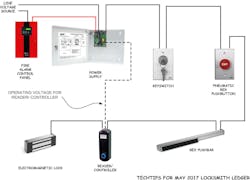

The basic elements of the electromagnetic locking system are the electromagnetic lock, the power supply powering the electromagnetic lock, and the additional ‘station controls’ which control the electromagnetic lock.

Best practices will generally call for redundancy in the life safety features of the system so that even of a failure were to occur in one station control (it fails to unlock when necessary), there is another station control which will also unlock in an emergency.

This sample configuration offers the basic requirements. The lock releases upon:

- Loss of line voltage

- Actuation of Fire Alarm

- Single action pressing on exit device which is mounted on the door. It is accepted that an exit device is a universally recognized means of opening a door. Applying pressure to the exit device actuates the switch (which is wired into the electromagnetic lock’s circuit), and physically opens the door.

- Additional REX button mounted on door frame with integral pneumatic timer which keeps electromagnetic lock released for 30 to 45 seconds. The RX button must be located close to door, and have a timer so it is not necessary to maintain pressure on the switch to maintain an unlocked condition.

- Auxilliary keyswitch which permits entry in case of failure of EAC (electronic access control). (At least one door should have a key override into the secured area).

Below are descriptions of some of the products than can be used to release the lock.

RCI 120 Series Switch Bar

This is a push bar with no latch or strike, ideal for easy egress to release electromagnetic lock by depressing the push bar.

• Specify SS1 (SPDT) 3A@30VDC (Inductive), 4A@30VDC (Resistive)

• Specify SS2 (Two SPDT) 3A@30VDC (Inductive), 4A@30VDC (Resistive)

• Standard lengths for 36" (3 feet) and 48" (4 feet) doors

• Can be field cut for undersized doors

Switches can be specified for all types of access controls. SS1 - SPDT rated 3A@30VDC (Inductive), 4A @ 30VDC (Resistive) SS2 - 2SPDT rated 3A @ 30VDC (Inductive), 4A @ 30VDC (Resistive)

906/908 Handicap & Exit Mushroom Buttons

This tamper-resistant button cannot be turned off or pried off and is ideal for request-to-exit applications

-

20-gauge stainless steel faceplate

- Standard model fits single-gang surface or recessed electrical boxes (optional)

- Hardware kit includes stainless steel tamper-proof screws and spanner bit

- Momentary, maintained or time-delay switches available

- 908 also available in French and Spanish

- 908 Model Engraved 1-9/16” (39.7mm) button (blank button available)

- 906 Model Engraved 1-3/4” (45mm) button (blank button available)

- 991N model can be mounted on narrow-style doors

- UL recognized microswitch

- 1 to 45 sec. adjustment time delay

- Push to Exit or Handicap symbol engraved options

- Quickly mounts to single gang box

960 Key Switches

The sleek, beveled-edge 960 key switches are designed to discourage tampering. Tamper-proof screws and a special driver are included with the key switch to prevent unauthorized removal of the faceplate.

The convenient lock-down cylinder bracket can hold two switches and is secured by the cylinder ring. The cover plate and switch mounting design can be used with most standard and recessed electrical utility boxes.

This product is ideal for commercial, industrial and institutional applications in high use areas including vestibules, storefronts, commercial, industrial and healthcare.

Standard Features:

- One-piece bracket with 2-position switch holder standard

- Heavy-duty 1/4" extruded aluminum faceplate (hardware kit includes stainless steel tamper-proof screws and spanner bit)

- Compatible with standard mortise cylinders with straight or clover cams in 1-1/8" or 1-1/4" cylinder lengths (optional)

- Brushed Anodized Aluminum or Brushed Anodized Dark Bronze finish

- 960N compatible with 1-3/4" narrow frame profiles

- Easy Lock-Down Dual-Switch Bracket

Options:

- Momentary, maintained or time-delay switches available

- LED

- Screen printed reset/override with directional arrows indicate the function of corresponding switch (optional on standard width only)

More Info: www.rutherfordcontrols.com

About the Author

Tim O'Leary

Tim O'Leary is a security consultant, trainer and technician who has also been writing articles on all areas of locksmithing & physical security for many years.