For a locksmith, it seems to me that doors are the object of their affection. The locking hardware and accessories are their affection, and the doors are where they install them.

Although there are individuals who specialize in locks who do not deal with door repair issues, I learned early on that whatever I’m planning to put on doors, whether it was a multiple door access control system or a standalone keypad, the success of my efforts have a lot to do with the working condition of the door on which I was installing the hardware, locks and electronics.

It is important to be prepared for dealing with an ailing door, because clients tend to favor full service firms, rather than having to find, contact then coordinate several vendors. Even if you use a subcontractor, you are the go-to-guy for your customer, and your likelihood of retaining the client and having successful projects increases substantially the more control you have over how the project is managed.

One locksmith I had an association with was a busy shop with split residential and commercial clients. Part of his work involved installing mortise locks on luxury homes, so he had a designated “Doorman” who was used to dealing with the mortise machine and had the physical strength to remove a door from its hinges and then reinstall it. The geographic area where the shop was located was densely populated and had a good mix of residential, commercial, industrial and commercial structures. Additionally this locksmith did not engage in bidding new installations; he was very busy and content with his traditional locksmithing activities. In a pinch the doorman could tackle more involved commercial door work, or a door specialist would be called in. This is not uncommon, since it is hard to be good everything.

A frequent service issue would be where the glass on an opening was broken. Sometimes the whole storefront would have been taken out by a stray vehicle. Glaziers and storefront mechanics would be called in when the going got rough. For less severe situations, every road tech was prepared to install and replace door closers and other routine items.

Another shop had several “divisions.” They had a retail lockshop, a sign division, a door division, a window gate division, and an electronic security division. I managed the electronic security division where we serviced retail banks and sold access controls, alarms and video surveillance systems. Since there was a dedicated door division, the owner’s stance on door repair was very different. Designated door crews were available for service and installations.

Along the way I became familiar with doors, and was able to size up a situation quickly and develop solutions for the client that worked for both my shop and the client.

These days, the ability to inspect and repair doors is a more valuable skill than ever with the yearly inspection of Fire Doors becoming a requirement in more and more jurisdictions.

Beyond traditional locksmithing, the locksmith’s realm has expanded to “keep up” as competition ramps up, markets shift and vanish, and other trades continue to encroach on our turf. It is imperative that the locksmith engage in ongoing in-service training and self-study of new products and the latest tools and technologies.

Dormakaba Physical Access Systems

Dormakaba’s newly introduced line of Physical Access Systems includes security revolving doors, personal interlocks, full height turnstiles, sensor barriers and tripod and waist height turnstiles to complement their extensive product and service offering.

“We have a deep line-up,” says Dave Rogers, business development manager for the Physical Access Systems product group. “We are excited to be exhibiting our systems at ISC. We’ll be the only company to be offering an end-to-end solution addressing all access requirements, and the ability to install and service our products for the lifetime of the facility.”

Facilities requiring controlled access of authorized personnel to sensitive areas can rely on dormakaba’s Security Revolving Door (SRD). The doors provide a practical and secure solution for any interior access point. The SRD Vision optical separation system accurately detects more than one person within a revolving door, then allows or denies passage as appropriate.

Full Height Turnstiles are recommended for securing the perimeter of buildings and property. Modular versions enable individual combinations of multiple units to accommodate bicycle doors, integrated doors, as well as emergency egress. The quiet low-energy drive offers push-assist which adapts to the speed of the person entering.

DORMA 8600 Series Door Closer

DORMA’s 8600 Series closers represent the latest in door control technology, designed to exceed the demands of today’s buildings.

The architectural grade 8600 Series is a non-handed surface applied door closer with adjustable spring power and backcheck positioning adjustment. Adjustable hydraulic backcheck will take effect at approximately 70 degrees. The 8600 has two independent, noncritical adjustment valves to control sweep and latch closing speeds. The backcheck positioning valve assures an effective ANSI backcheck range on parallel arm applications. All closers to have field adjustable spring power from size 1 to 6 and meet barrier-free requirements.

With features like the full range spring power adjustment, the 8600 Series closer provides the flexibility needed to meet the many demands of commercial and institutional applications, including ADA barrier-free accessibility requirements.

The modern slim cover, flat form arm, and architectural finishes provide the aesthetic qualities required of architectural grade closers. In addition to all of these features, the 8600 Series is backed by DORMA’s 25-year warranty.

Features:

- Available as 8616 closers for interior and exterior doors.

- Meets barrier-free requirements (adjustable size 1 thru 6).

- Non-handed for regular, top jamb and parallel arm applications.

- Adjustable backcheck standard. Controls opening motion during abusive or abrupt opening.

- POS backcheck positioning valve (standard) maintains effective backcheck range on parallel arm applications. Valve is accessible with the closer installed.

- Optional delayed action adjustable with a separate independent valve. Delays door closing to allow unobstructed passage through the opening.

- Slim plastic cover standard. Full plastic or metal cover optional.

- Designed to minimize change in closing speed during severe temperature changes.

- Aesthetically pleasing and easy to adjust steel flat form arm assembly.

- Optional arms, plates, and brackets available for special applications.

- SNB1 sex nuts and machine screws for 1-3/4" thick doors included standard.

- Available with optional self-drilling screws for steel door and frame applications (DPK86) or self-tapping screws for aluminum door and frame applications (TPK86).

- No slip, octagonal bore spring adjustment standard.

Certifications:

- ANSI/BHMA A156.4 Grade 1 certified.

- U.L. & C.U.L. listed.

- Meets UL10C and UBC 7.2 (1997).

- Meets ANSI/BHMA A117.1 and ADA for barrier-free accessibility.

- CSFM approved.

Manual door closers, including those certified to meet ANSI/BHMA A156.4, when installed and adjusted to conform to ADA or other reduced opening force requirements, may not provide sufficient power to reliably close and latch a door. Refer to catalog for ED800 Low Energy Operator to meet reduced opening force requirements without affecting closing power.

More Info: www.dorma.com

Karpen Steel Doors

Karpen Steel Door publishes an email newsletter, and their most recent one couldn’t have arrived at a better time as I was preparing this article on commercial doors.

Here are some excerpts, but I suggest you head on over to their website, www.karpensteel.com, to check out the resources and sign up for the newsletter.

Karpen is a custom manufacturer that works directly with customers to work out the details to meet the specific requirements of each opening. Through their high level of customer service and innovative manufacturing ideas, they lead the industry as The Custom Quick Ship Professionals.

Karpen sells only through their certified distributor network and uses only the highest quality materials in making their custom doors and frames. Each one is manufactured to the most exacting standards.

Their product line includes: 12, 14, 16 & 18 gauge doors and 10, 12, 14, 16 & 18 gauge frames, UL Labeled doors and frames, temperature rise doors, dutch doors, acoustic assemblies, lead-lined doors and frames, knocked down frames, pocket door frames, 2-piece slip frames, elevator, sub-buck and shadowline frames, round top doors and frames.

For architects and specifiers, the choice of door and frame materials often comes down to this: steel or something else?

Steel is famously strong, but there are additional advantages to bear in mind when you ask yourself, "Why Steel?"

Steel provides the best long-term value in the door and frame industry. It lasts longer, requires the fewest repairs, and is sturdier than other products. Steel’s natural strength also outperforms other materials in security, fire rating, sound reduction, vandal resistance, sanitation, and more.

Hollow metal will outperform wood, aluminum, and fiberglass in demanding environments. Even when those other materials use special cores or other techniques, they are still unable to match the performance and longevity of hollow metal.

A beneficial byproduct of the strength and durability of hollow metal is the low total cost of ownership. Properly installed and maintained hollow metal doors often last 30 years or longer. As the years pass, steel doors can be inexpensively repaired in the field while softer, less durable wood and aluminum doors will have to be replaced.

Are you seduced by the so-called warmth of wood? Consider this: Today’s steel doors offer endless options for attractive appearances. Whether you are looking for a modern stainless steel appearance, a vibrant colored finish, or even a faux finish, steel’s versatility allows it to satisfy the aesthetic requirements of most projects. And don’t forget all those advantages of performance and longevity!

Steel doors and frames even help the environment, as steel is the most recycled material in North America.

According to Karpen, when it comes to the specifications of any door or frame order, details are key. The more details are known, the more confident both parties can be.

A major reason for their cross-checking procedures is to get at least one fresh pair of eyes on each order before it moves to the next step. This allows them the opportunity to develop additional questions that may be asked to ensure we have as much detail about the order as is needed.

However, in some instances certain details aren’t available because of the particular conditions on the job. In these situations that customers can only provide their best guess based on the information they do have. Fortunately, in some of these cases Karpen can build some flexibility directly into the product in order to account for potential variances.

Their Split Jamb Frames, for example, provide customers a level of comfort that the final product will fit even when some details about the opening are unknown. The most common application for a split-jamb frame is a situation in which the exact thickness of the wall cannot be determined until the old frame has been removed.

Often times because of security or scheduling reasons the existing old frames will not be removed until the new frames have arrived on-site for installation.

Hager Door Components

“One of the biggest problems seen with exterior commercial doors deteriorating is failing to incorporate the proper hardware during the specification process or when supplying the doors. One of the largest factors of improper hardware utilization is driven by cost – appropriate hardware usually brings up the total cost of the door, which can act as a deterrent for the proper products specified being supplied,” according to Hager.

Products typically missed on exterior applications are overhead door holders and stops. These are recommended where any other type of door stop cannot be utilized due to floor or wall conditions. Even when doors are furnished with door closers, it is recommended to use an overhead door stop because a closer is not intended to stop the door and should not be expected to perform the functions of a door stop. Most closers have the ability to include an arm with a built-in stop; however, many times exterior conditions will become extreme and the closer arm or closer itself will typically fail. Incorporating an item that is designed to only stop the door is always the best practice. Depending on the door configuration, floor stops and wall stops are also options to incorporate into an exterior opening.

Hager Companies offers a variety of door hardware products to accommodate virtually all door openings. Two great overhead door holder and stop options from Hager include the 7000 Series Grade 1 Heavy Duty and the 6000 Series Grade 2 Medium Duty. Both options feature adjustable arms for easy installation and adjustability in the field, slide track designs, and heavy shock absorber springs providing 5-degree to 7-degree compression before the dead stop.”

Hager Companies overhead door holders and stops have been engineered and designed to meet the requirements of many door applications. The streamlined channel design along with the adjustment arm accommodates various door sizes and applications. The adjustable arms simplify the selection by combining door width ranges into only two sizes of overhead door holders and stops. This feature makes installation simple and minimally impacts a customer’s inventory.

The 7000 and 6000 series of overhead door holders and stops are mounted at the top of the door to eliminate tripping hazards and vandalism that are typical of floor or wall mounted stops. The purpose of the overhead door holders is to absorb the abusive shock with a heavy duty spring. They evenly distribute the load and impact along the entire track of the unit. Overhead door holders and stops are compatible with a variety of door closers and are ideal for meeting the demands of high traffic areas.

The 6000 Series Grade 2 Medium Duty Overhead Door Holder includes adjustable arms for easy installation, a slide track design and field adjustability. The heavy shock absorber spring provides 5° to 7° compression before deadstop. Special templating is available upon request.

Certifications:

- BHMA Certified ANSI A156.8

- UL/cUL Listed for up to 3 hours (stop only)

- UL10C Positive Pressure Rated (stop only)

- UL10B Neutral Pressure Rated (stop only)

6000 / 7000 Series Features:

- Five-year warranty

- mounting style:

- Concealed

- Surface DOORS:

- Single acting doors for concealed and surface mounted

- Double acting doors for concealed mounted only

- DOOR THICKNESS: 1-3/4" (44 mm) thick door

- Standard - 1-3/8" - 2-1/4" (36 mm - 57 mm) thick door

- Optional FUNCTIONS: - 15 Friction , 16- Stop Only, 17- Hold Open

- Door Sizes

- 6000 Series Door Width: - Size 1 (SZ1) = 18"-33" (concealed mounted) 20"- 33" (surface mounted) - Size 2 (SZ2) = 33"-51":

- 7000 Series Door Width: - Size 1 (SZ1) = 24"- 40" - Size 2 (SZ2) = 41"- 55"

- Non-handed OPENINGS:

- Degree of opening is fully adjustable and can be adapted to changing needs between 85°-110°

- Materials: - Steel, - Stainless steel

- Finishes: - US3, US10B, US26D (for steel), US32D (for stainless steel)

- ALM FASTENERS: - Standard screw packet included for wood or metal door and frame applications

Hager Pivots

If you’ve been working on doors, you will agree that a common point of failure is the hinges and pivots. They carry the moving weight of the door and are subject to abuse and weather, and are rarely maintained.

I can recall situations where a door failure could be traced back to a pivot becoming loosened due to vibration and use, and then after an extended period, the pivot and the frame and door to which it was installed became severely damaged, complicating the servicing of the opening.

Locksmiths should train themselves to observe maintenance issues on doors while they are rekeying or replacing locks and door accessories before they reach a critical state.

HAGER has an extensive inventory of door components and tech support to help you through when you need it.These pivots we’re showcasing are in the heavy duty range of product. Your doors may not require something this robust.

495 Ball and Thrust Bearing - Heavy Weight

Dimensions: Top 8 5/8 x 1/4-20 1 1/2 x 14

Recommendations for use: - For doors up to and including 3'0'' x 8'0'' (91 x 244 cm) weighing maximum of 350 pounds, apply all three pivots #495, #496, #497 –

For doors over 3'6" (107 cm) up to 4'0" (122 cm) in width, add one additional intermediate pivot #496 - For each additional 12" (305 mm) in door height over 8'0" (244 cm) add one intermediate pivot #496

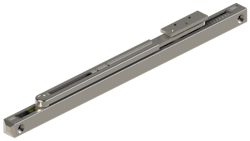

496 Ball and Thrust Bearing Intermediate

Dimensions: 10 5/8 x 1/4-20 1 1/2 x 14

Recommendations for use:- For doors up to and including 3'0'' x 8'0'' (91 x 244 cm) weighing maximum of 350 pounds, apply all three pivots #495, #496, #497

For doors over 3'6" (107 cm) up to 4'0" (122 cm) in width, add one additional intermediate pivot #496

For each additional 12" (305 mm) in door height over 8'0" (244 cm) add one intermediate pivot #496

More Info: www.hagerco.com

LCN 4040XP Closer

The 4040XP is LCN’s most durable heavy duty closer. Designed for the most demanding, high-use and abuse applications, it combines a tougher, bolder construction with proven LCN technology. The result is a closer that’s stronger, smarter and delivers remarkable value in a variety of applications.

Closers are subject to millions of opening and closing cycles, so durability is essential. LCN’s cast iron closers like the 4040XP won’t let you down — regardless of how many people go through the door or how hard they slam and push against it. Heavy-duty cast iron is the strongest and most reliable cylinder material available. It features superior burst and yield strength as well as natural graphite that self-lubricates parts to reduce wear on internal components.

LCN’s all-weather fluid reduces maintenance and ensures consistent performance through every season. Set the control of the door once and you’re done, no matter what happens with the environmental conditions. The patented green dial on the 4040XP makes spring adjustments fast, easy and foolproof.

Features:

- Cast Iron

- Forged Steel Arm

- Double Heat Treated Steel Pinion

- All Weather Fluid

- Non-Handed

- LCN Green Dial spring force indicator

- Fast & Accurate Installation

- Strongest pinion ever- at 3/4” journal diameter

- Widest bearing ever- at 5/8”

- Tested and certified under ANSI Standard A156.4, grade one

- Closers to meet ADA requirements

- UL & cUL Listed

- 4040XP can be used with all 4040 accessories

More Info: www.allegion.us

Steel Door Institute

The Steel Door Institute, www.steeldoor.org, offers a wealth of information resources and ideas from the national trade association which deals with steel doors.

The Steel Door Institute has just created a Door Selector Tool to help architects select the appropriate doors for their projects. Just answer a few basic questions and the tool will show the commonly specified performance levels and door designs for that type of opening.

As one architect commented recently, “I don’t want to reinvent the wheel. Tell me what’s usually done and I’ll take it from there.”

“Our hope is that this tool will save architects time. Rather than manually researching the common door constructions for each opening in a building, architects can bookmark this tool and reference it anytime to see what is often specified for that location.”

Steel Door Institute members are:

Ceco Door, an ASSA ABLOY company: www.cecodoor.com

Curries, an ASSA ABLOY company: www.curries.com

Dean Steel: http://www.deansteel.com/

Door Components, Inc.: www.doorcomponents.com

Hollow Metal Xpress: www.hmxpress.com

Mesker Door: www.meskerdoor.com

Pioneer: www.pioneerindustries.com

Republic Doors & Frames, an Allegion company: www.republicdoor.com

Security Metal Products, an ASSA ABLOY company: http://www.secmet.com/en/site/secmet/

Steelcraft, an Allegion brand: http://us.allegion.com/brands/steelcraft/Pages/default.aspx

About the Author

Tim O'Leary

Tim O'Leary is a security consultant, trainer and technician who has also been writing articles on all areas of locksmithing & physical security for many years.