Whether you are installing or servicing mechanical locks or electronic access control, it is inevitable that you will encounter a door that has seen better days, but is not ready to be replaced. You will need a specialized locksmith accessory referred to as a wrapper.

Wrappers are designed for specific thickness doors, available in a variety of architectural finishes. They come in different heights, backsets, and also with the specific prep required for specific lockset or standalone access control models. It is definitely not a case of one size fits all, although in an emergency it is possible to make modifications to the wrapper so it can be used and avoid a callback or a delay in securing the opening. Damage to the door can cause problems beyond simply weakening the physical integrity of the door.

Although wrappers are metal (typically stainless steel) and fire proof, they may not be UL Listed for use on fire rated openings. While the wrapper may return a door to functional condition, it is up to the local authority having jurisdiction (LAHJ) to decide if the door still meets code after the wrapper has been installed. If the wrapper is being used to literally hold the door together after a major damage, the LAHJ is likely to fail the door.

PROBLEM CAUSED BY SCREWING AROUND: Not too exotic, but probably the most frequently encountered door problem requiring a door wrapper is when the door is damaged in the area where the latch face is attached to the door. The latch is the point of impact every time the closes, and the latch face's position is totally dependent on the cylinder backset and the depth of the latch mortise. Therefore the latch may loosen; maintenance people will try to tighten it; the screws will soon fail to grab because the door material has degraded or cracked; and out comes the screw collection. I've seen all types of fasteners used, including overly long deck screws that bottomed out on the side of the lock cylinder and failed to tighten. Or they tried a re-entry by aiming the screws at oblique angles so as to avoid hitting the cylindrical lock body which didn’t work and further damaged the door. What a mess!

PROBLEM CAUSED BY FORCED ENTRY: I’ve seen many of this type of damage. Fraternity houses come immediately to mind. The young men come home, can’t find their key and kick, shoulder or otherwise force the door. The area around where the door lock is or was located gets splintered, and perhaps the lockset is damaged.

If the door had a cheap lockset, the lockset may have surrendered before the door was majorly wrecked. If it was a commercial grade lock or standalone access lock, the lock may have survived, but not so much the door. Even if the client agrees a new door is warranted, you may have to temporarily secure the opening with a wrapper.

DAMAGE CAUSED BY SLOPPY DOOR PREP: I can recall numerous situations where it was supposed to be an easy lock swap, and instead turned into mortal combat. Somehow the previous person working on the door (I won’t refer to the person as a locksmith out of reapect for locksmiths) managed to trick the lock into fitting together onto the door so it worked well enough to pass for a completed installation.

But trying to put a new lock into the prep turns into a big problem. Alignment between the latch hole and cylinder prep is a favorite. I’ve seen prep where it looked like the installer used a hammer and flat blade screwdriver to make a hole for the latch. Another winner is where the cylinder face hole is at the wrong backset. Even though most professional locksets are moderately tolerant if dimensions are off a little, there is a limit.

As we’ve noted in the past, tabs on the cylindrical lock body and fingers on the latch where the two assemblies meet which must interlock for the lock to work reliably. This is separate from the tab on the latch which the cylindrical lock interlocks with to retract the latch. The mortise of the latch faceplate is another typical occasion of sin for the shoddy installer.

Trying to correct some of these problems without the proper tools may not always be possible, or the best use of your time. And the end results may not meet your customer’s expectations.

Redrilling using a fixture, and then covering the wound with a band aid (wrapper), makes quick work of the job and results in a properly functioning and attractive opening.

In older facilities where the lock may been replaced several times and the door has withstood moderate abuse, even if the prep was done correctly initially, time has taken its toll and additional measures are warranted.

After witnessing the sloppy installations passed off as professional installs over the years, it is easy to empathize with facility guys who throw their hands up in frustration when they encounter these types of issues during what they expected would be a routine lock swap. Actually, I do more than empathize with them, I tell them it took me years to be able to make it look easy, and I truly appreciate their business.

A plastic drill fixture from the hardware store might last for one installation, but I prefer a drill fixture designed for professional use which will provide the options, provide for an accurate door prep, and which will wait patiently in your van until its next needed.

There are also drill fixtures designed for specific model locks, such as standalone access controls which require additional holes besides the cylinder and latch holes. These fixtures are handy when there are lots of openings to do, and your help may not have achieved your skill levels of accuracy and concentration.

When you are attempting to install a lock on a door which was not properly prepped, you may need to redrill it. It is difficult to move the center of a hole a small distance because there is no door material remaining to center your hole saw, and you may only need to enlarge one side of the hole. A professional drill jig once again is the answer.

Following are some of the specialized tools that will make your job a little easier.

HIT-134 Drill Guide

Major Manufacturing was created in 1976 as a subsidiary of Major Lock Supply. The company was split off from Major Lock Supply in 1992 and restructured to better serve the trade by providing specialty installation equipment, servicing tools and supplies not otherwise commercially available to the professional locksmith and installer.

Major Manufacturing is headed by Bill DeForrest, a professional in the security field with over 30 years of hands-on experience in locksmithing, wholesale distribution, equipment design and production. Signature products include the Kee-Blok and the multi-faceted Hardware Installation Tools (HIT Series).

One of the numerous HIT series is the HIT-134 drill guide for Codelocks 5000 Series electronic locks. This unit thru-bolts to door, using the existing 2-1/8" crossbore for alignment. All required mounting and function holes are located with hardened drill bushings, on both sides of template, to allow drilling from either side of door. Standard drill guide will accommodate doors with 2-3/8" or 2-3/4" backset and up to 2" thick.

A few moons ago I had to slap in a dozen CodeLocks in a bustling school with badly worn doors. It was definitely a big help. Did you ever kiss your drill guide?

More Info: www.majormfg.com

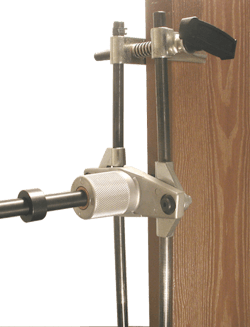

Bulls Eye BUL-1 Installation Tool

Like all of A1’s many specialty products, A1’s Bulls Eye BUL-1 Installation Tool was designed specifically for locksmiths. The Installation Tool comes ready to drill 1½ and 2⅛ cross bores and uses conventional hole saws.

The Bulls Eye Installation Tool includes an automatic toggling backset adjustment and self centering alignment guide which allows users to easily drill a latch hole.

The clamping surfaces are lined with a neoprene surface that virtually eliminates slipping when properly mounted to a door. Users also have the ability to add straps and another BUL-2 for interconnecting locksets or dual bores.

The device looks and works great, and I’m not embarrassed to pull it out of my tool bag and mount it on the door. I probably could have sold a few along the way if I had them in stock in my van.

A1 products are available through these locksmith distributors: CLARK, HL Flake, Lockmasters and U.S. LOCK. More Info: www.demanda1.com

Don-Jo Manufacturing

Don-Jo offers a complete line of architectural hardware accessories and has been doing so for as long as I can remember. Products include: Accessory Hardware, Bolts & Latches, Door Controls, Filler Plates & Signs, Hinges, Kick Plates & Door Edges, Latch Protectors, Pivots, Pulls, Push & Pull Plates, Stops, Holders & Bumpers, Strike Plates, Templates and Wrap Arounds.

Their website, www.don-jo.com, has all the product information you require to identify the correct product, and you can always give them a call if you have a question. Tell Eric I sent you.

Pro-Lok Killer Jig Installation Kit

Before Pro-Lok™ was manufacturing industry products such as Blue Punch™ Key Machines, Installation Tools, Kalifornia Key Chains™, Auto Entry Tools, and many other industry products, Pro-Lok founders were practicing security professionals. Operating three successful security stores in Southern California, the initial experience working the sales counter, answering customer phone calls, dispatching services vehicles, bidding on contract jobs, and merchandising retail stores has provided Pro-Lok with the real world knowledge and foundation to build and expand products into the security market. Their 17 patents acquired since 1983 is a testament to their ability to find solutions to many of the industry’s problems.

Many Locksmith Ledger readers may already be familiar with Pro-Lok tools and Blue Punch Key Machines however; many do not know Pro-Lok is a leading supplier of firearm safety products in the firearms and sporting goods industry. Pro-Lok has supplied the sporting industry with millions of firearm safety products, safes, and key accessories.

Pro-Lok’s tool division designs and manufacturers products for auto opening, hardware installation, and Blue Punch™ Key Machines. Their retail products division is comprised of Pro-Lok gun locks, Pro-Lok safes, Kalifornia Key Chains and Entry Armor security product lines.

Pro-Lok’s Killer Jig Installation Kit (Model INJIG-KJ) includes everything a professional installer needs to prepare doors and door jambs for hardware, all stored in a heavy duty case with custom Polyurafoam interior to hold and protect each tool in its designated area.

The kit includes a professional quality Killer Jig made from lightweight machined aluminum with hardened bushings and a durable powder coated finish,; as well as the following accessories: two cross-bore spur bits, an edge-bore bit, a strike locator, four heavy duty latch and face plate marking tools (including a unique deadbolt height gauge) and a set of two different sized bushing plates.

The Entry Armor Stainless Steel Wrap Around Door edge guard repairs, reinforces and protects wood or metal doors from forced entry. It is compatible with key-in-knob lockets or deadbolts and designed for residential, commercial or industrial use. Duronodic and Stainless Steel finishes are available.

Dimensions:

- 1-1/2″ in. Bore

- 2-3/8″ in. Backset

- For use on 1-3/4″ in. thick doors

- Size 4″ X 4-1/2″ in.

More information: www.pro-lok.com

About the Author

Tim O'Leary

Tim O'Leary is a security consultant, trainer and technician who has also been writing articles on all areas of locksmithing & physical security for many years.