For the purpose of this article, we will discuss surface-mounted door closer basics to better understand the design, operation and limitations of a mechanical door closer. Optimizing the installation of a door closer can be very beneficial by requiring less opening and resulting closing force. Less force means more possibility to meet code requirements.

MOST IMPORTANT: Before installing or servicing a door closer, make sure the door hardware is in proper operation. A door that rubs along the threshold, floor or jamb edges will most likely not close under the power of a proper sized door closer. On rare occasions a latch bolt has worn to a point, making it difficult to retract when pressing against the strike plate. This results in the door not latching. No matter what the problem is, it must be resolved to ensure smooth, non-restricted closing and latching.

In the non-residential world, for almost every door a person physically opens, a mechanical door closer closes the door. The door closer closes, rather than slams shut, a door.

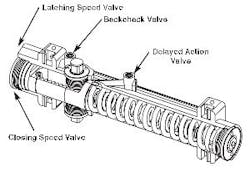

Simplified, a door closer is a spring loaded, adjustable hydraulic system and through the use of specifically located valves, it is capable of safely closing and latching a door using only the power provided by the person who opened the door. When a person opens a door, the closer spring compresses and the hydraulic fluid moves away from the compressing spring. As the door closes, the spring expands and the fluid is forced into the area of the expanding spring. Valves positioned along the closer body determine how fast the fluid moves as the spring expands.

The process of opening and closing a door equipped with a mechanical door closer can be divided into four or five stages.

The first stage is when the person swings open the door. Depending upon the obstructions within the swinging area, the door may be able to be opened slightly more than 100 degrees (providing sufficient room for traffic flow) to fully open, up to 180 degrees. The opening can also vary by the type of closer arm installed.

Note: When installing, you will usually gain additional adjustability if the door closer is mounted to allow the greatest degree of opening.

When there is a choice of how far to open the door, consider the traffic flow. If there is high traffic through the doorway, the greater the opening, the longer the time the door is in the opening area, the more people who will walk through.

The second stage is the backcheck when a special valve in most door closers controls the opening swing. The door then slows smoothly prior to the end of the swing.

Note: A solid stop should always be installed, as the closer’s backcheck was never designed to be a doorstop. Without a solid doorstop, additional pressure is exerted against the mounting screws, and the spindle, arms and shoe or foot shortening the operational life expectancy of the door closer.

The additional stage is Delayed Action, an available feature on many door closers. Delayed Action holds the door fully open for a minimum number of seconds, providing additional time for passage through the doorway.

If the door closer is equipped with a delayed action valve, the door will stay in the open position for an adjustable amount of time. For high traffic doorways, holding the door open does increase traffic flow.

The next stage is the closing speed that controls how fast the door swings from open to about six to ten inches or approximately 15 degrees from the closed position. Remember, because the spring has been compressed, its power is very high at the open position. Standard door closer power decreases dramatically as the spring expands. If the spring power is released too quickly, the door may slam shut or there may not be enough force remaining to latch and secure the door.

The final stage is the latching speed, which controls the final inches or degrees of the closing arc. The force closing the door is controlled by the closer spring. The optimum installation is when there is just enough spring force left in the closer once the door is latched. If there is too much spring force left when the door is latched, this force is wasted and there is probably too much spring force being made available. Too little spring force will result in either the door not latching or the door not latching occasionally. For these reasons, the most critical adjustment is the latching speed valve.

Following the door closer manufacturer’s installation instructions is critical for the door closer to operate properly and consistently. Door closers have been designed to change their arm geometry as the door opens, increasing the leverage onto the door. This change offsets the spring compression, requiring less force exerted in order to fully open the door.

Before installing a door closer, considerations include fully adjustable versus sized door closers, the installation method, the choice of arms and positioning of the adjustable arm in relation to the shoe or foot.

Are there advantages of a fully adjustable door closer versus a sized door closer? Yes and no. The fully adjustable (one through six) door closer can be used on most door sizes, eliminating the need for a locksmith to stock multiple door closers. However, if the sized door closer offers the ability to increase the closing power by 50 percent, then the largest sized closer, a number six, can offer the closing force of a six and a half to better accommodate large or heavy doors.

Note: Some door closer manufacturers offer varying power adjustments for sized door closers. Some of the power adjustment options include 15, 35 and 50 percent adjustable increases.

The choice of installation also affects the closing power of a door closer. The Regular (also called Standard) or Top Jamb installation provides better leverage (requires less power) to operate a door than does a Parallel Arm or Track Arm installation. On average, use one closer size less for a Regular or Top Jamb installation than a Parallel Arm installation.

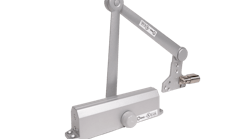

The Regular application mounts the door closer onto door face and the shoe onto the frame. The shoe arm (adjustable arm) assembly is mounted perpendicular to the door and frame. This is the only pull-side of the door application for a door closer. The regular application providesthe most power efficiency.

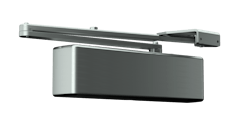

The Top Jamb applications mounted the door closer onto the push side of the door locating the closer onto the face of the frame and the shoe onto the door. For this installation, there must be sufficient clearance for the body of the closer. Most door closer manufacturers offer mounting plate options to resolve clearance issues.

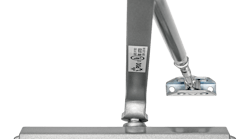

The Parallel Arm mounted door closer is installed onto the door and the arm is mounted onto the underside of the frame. Parallel arm mounted door closers require either a separate mounting bracket or the bracket is built into the parallel arm. The closer and the arm are almost parallel to the door face. When the door is closed, only the soffit plate usually projects beyond the frame face.

Note: The parallel arm application geometry is less efficient than a regular arm or top jamb application. For large or heavy doors, parallel arm installation may not be the best choice.

Unfortunately, the Parallel Arm installation has more aesthetic appeal as well as vandal resistance as the arms run parallel to the closer, not perpendicular. A door closer arm sticking out into a room is an invitation to problems.

A number of door closer arms have the option of an arm power or leverage adjustment for Regular or Top Jamb installations. The standard arm (or standard specialized application arms) has the option to increase closing power by up to 15 percent. This is accomplished by moving the adjustable arm towards the hinge side of the door. Closer manufacturers do this by either a two or three hole foot or shoe or using an offsetting shoe or foot.

In the standard position, the mounting hole is at the normal dimension. By rotating the foot or shoe, the adjustable arm is offset to provide up to 15 percent power increase. For a two hole shoe, moving the adjustable arm closer to the hinge side of the door can increase the power up to 15 percent. With a three hole shoe, moving the arm from the center position to the hinge side of the door increase the power up to 7 ½ percent. Moving the arm from the center position to the latch side of the door decrease the power 7 1/2 percent.

Finally, when installing a door closer, be sure to follow instructions regarding positioning or pre-loading the fixed length arm. The basis for these instructions is to place rotational pressure on the arm when the door is in the closed position. Without some pressure, there would not be enough spring pressure to latch the door.

Note: For a Regular or Top Jamb application, the fixed length arm is at an angle where the adjustable arm is always perpendicular from the face of the door.