As work patterns shift to telecommuting, the residential security market is growing and competing for equal time from professional security providers. This market is producing healthier and healthier revenue streams, and customers demand door hardware solutions well beyond deadbolts and the occasional rekey.

This month we’ll install a light-duty door closer on a residential door. The process begins with selling the client on the value of door closers, and then involves the careful planning and professional installation of the device.

The modern door closer takes the energy a person uses to open a door and stores it by compressing a spring; then, when the door recloses it releases the energy through the closer arm using hydraulic oil and valves, which control the speed and force to reclose the door, ideally without letting it slam.

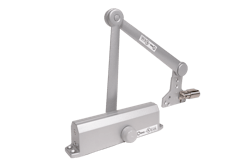

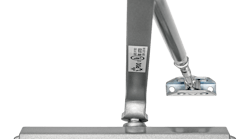

The PDQ 3100 light-duty surface door closer is a versatile door closer that is available with a full complement of architectural accessories. It features a high-strength cast aluminum body and an optional plastic cover and comes in four finishes. In addition, it is UL listed for a three-hour fire door and is Americans With Disabilities Act (ADA) compliant. It carries a 25-year warranty.

Light-duty door closers are typically used on interior or exterior doors that have low to moderate traffic/usage.

The ANSI BHMA 156.4 applies to surface-mounted door closers, overhead concealed door closers, and concealed floor closers. Testing includes the number of door cycles, door operation, door closing force, and finish tests all performed in under a neutral air pressure laboratory between 60- and 85-degrees Fahrenheit.

Door closer product grades are categorized as grade 1, 2, or 3. Grade 1 is considered the highest grade or most heavy duty, while grade 3 is the lowest grade. This PDQ closer is Grade 1. A Grade 1 door closer is always the best bet for quality, performance and reliability, and is by far the best value for anyone who is in the market for a reliable door closer. The heavier-duty internal components result in Grade 1 door closers that last for decades if not for a lifetime. I’ve seen potbelly closers from the Stone Age that outlived the buildings where they were installed.

Applications for light-duty door closers include aluminum storefronts, assisted living, hospitality, interior offices and multifamily. Some single-family homeowners are requesting these door closers to make sure doors securely close to keep children and pets safely inside, or to keep from heating and air conditioning the great outdoors.

Mounting Options

Regular Arm: Regular-arm mount is a pull-side application with double lever arm. The closer mounts on the door and the arm mounts to the frame. It provides the most efficient operation for a door control and is commonly used on in-swing doors from corridors or other interior doors. Regular-arm mount is a poor choice for exterior out-swinging doors as it would put the closer on the exterior of the building. The arm assembly projects directly out from the frame. That may be a concern for vandalism or aesthetics.

Top Jamb: Top jamb mount is a push-side double lever arm application that offers the best alternative to regular-arm mount. The closer mounts to the frame and the arm mounts to the door. This application is commonly used on exterior out-swinging doors. It is a poor application for in-swinging doors from a corridor as it places the closer arm in a visible application projecting into the corridor. The arm projects out, similar to regular arm mount. Therefore, it can be a concern for vandalism or aesthetics.

Parallel Arm: Parallel arm mount is a push-side double lever arm application. The closer is installed on the push side of the door and the arm is mounted to a parallel arm adapter plate installed to the frame soffit. The arm is approximately parallel with the face of the door, eliminating the projection condition evident with regular arm and top jamb applications. Parallel arm is often preferred where aesthetics or vandalism are concerns. Parallel arm is less efficient than regular or top jamb mounts due to the geometry of the arm.

Parallel Arm (DS/DSHO) Stop Arm: The parallel stop arm mount is an enhanced version of the parallel arm application that incorporates a heavy-duty rigid arm and soffit plate with limiting dead stop. The dead stop feature is field handed. The closer’s back check function should be adjusted to cushion the impact of the stop. The parallel stop arm is intended for use where an auxiliary stop cannot be utilized.

Installation Steps

1. We will be installing a regular-arm door closer. With any door closer installation, the first step is to read and understand the manufacturer’s recommendations and code requirements.

If there is already a closer on the opening, measuring the door using a force gauge and observing the door closing are good ways to determine the functionality of the door closer and the condition of the other components on the door. It is also the first step towards adjusting the door closer.

2. Check to be certain the door closes properly. There should not be any door warpage or loose-fitting hinge screws. If screws are loose and they will not tighten, replace them with longer and larger diameter screws or repair the frame as needed.

3. Make certain that the door lock operates properly and the latch slides squarely into the strike opening.

4. Remove any trim or hardware which will interfere with the installation. I removed the side and top door moldings.

5. Carefully mark the locations for the mounting holes using the installation template and tri square. I like to measure down from the top of the door, and mark both sides of the door. The mounting holes are more likely to align when done this way. I prefer through drilling and using sex bolts to hold the closer on the door. Not using these fasteners may allow the closer to eventually twist and torque and loosen on the door. A loose door closer is a dangerous and an unprofessional installation.

The location of the closer and shoe are determined by the type of installation, and the maximum desired door swing the door. The template is marked for a 180-degree swing to full open.

Locate where the arm attaches to the door frame. Through bolting is not typically used, and is determined by the location of the door operator.

6. Attach the arm to the frame and the closer. The length of the arm must be adjusted to apply preload on the closer.

7. Adjust the closer to provide the proper operation.

1- The arm length

2- The spring inside the closer

3- The backcheck

4- The sweep

5- The latch

More info: https://www.pdqlocks.com/products/3100

Sidebar Accessibility Concerns

The terms universal design, barrier-free design and ADA-compliant are often used interchangeably. However, these terms aren’t synonymous and each refers to different approaches to building construction.

For those with disabilities, some buildings are more difficult to enter, exit, and maneuver through. Barrier-free design is an approach to construction that takes into consideration the needs of those with a disability. Barrier-free design elements are features like wooden or metal ramps leading to the exterior doors, widened hallways that can accommodate wheelchairs, lower counter tops for ease of access, and the removal of shelves under sinks for wheelchair access.

Universal design picks up where barrier-free design starts. In addition to accommodating individuals with a disability, universal design makes provisions for folks of any level of ability. Universal design accommodates individuals of different heights, physical and mental abilities in an aesthetically pleasing way. Some universal design features include lever door handles instead of knobs, ovens situated at multiple heights in the kitchen, no step entryways, and automatic faucets.

Barrier-free and universal designs accomplish different ends, but both reinforce the notion that buildings should be highly accessible, aesthetically pleasing, functional and comfortable.

ADA compliance means openings meet specific standards set by the American Disabilities Act.