All door closers must meet ANSI/BHMA 156.4 Door Controls - Door Closers standards. The ANSI BHMA 156.4 applies to surface mounted door closers, overhead concealed door closers, and concealed floor closers. Testing includes the number of door cycles, door operation, door closing force, and finish tests all performed in under a neutral air pressure laboratory between 60 and 85 degrees Fahrenheit.

Door closer product grades are categorized as Grade 1, 2, or 3. Grade 1 is considered the highest grade or most heavy duty, while Grade 3 is the lowest grade or lighter duty.

The door closer grade is determined by the number of door cycles it has completed during testing. One door cycle is defined as the door being pushed to full open position and then closing.

How does the door size correspond to the door closer duty and grade? Consider the door location and size. For example, heavier commercial doors come with more wear and tear, in general. A heavy door requires more force to close. Wind and stack pressure affect the grade required. A Grade 1 door closer is always the best bet for quality performance and reliability, especially for exterior doors with heavy use in demanding environments.

Grade 1 Door Closers: Tested for 2 million cycles at 60% efficiency

Grade 2 Door Closers: Tested for 1 million cycles at 50% efficiency

Grade 3 Door Closers: Tested for 500,000 cycles at 50% efficiency

Applications for light-duty door closers may include aluminum storefronts, assisted living, hospitality rooms, interior offices and some residential single- and multifamily openings.

Door closers are critical door hardware and have always been a significant revenue stream for locksmiths.

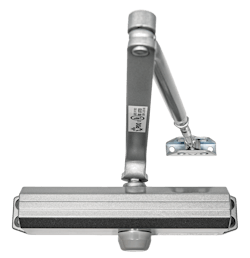

There are two types of door closers. Surface-mounted closers are more common than concealed closers (concealed in the floor, threshold or header).

Mounting Options

Regular Arm: Regular arm mount is a pull-side application with double lever arm. The closer mounts on the door and the arm mounts to the frame. It provides the most efficient operation for a door control and is commonly used on in-swing doors from corridors or other interior doors.

Regular arm mount is a poor choice for exterior out-swinging doors as it would put the closer on the exterior of the building. The arm assembly projects directly out from the frame. That may be a concern for vandalism or aesthetics. Regular arm application can be used with non-hold open or hold open arms.

Top Jamb: Top jamb mount is a push-side double-lever arm application that offers the best alternative to regular-arm mount. The closer mounts to the frame and the arm mounts to the door. This application is commonly used on exterior out-swinging doors. It is a poor application for in-swinging doors from a corridor as it places the closer arm in a visible application projecting into the corridor. The arm projects out similar to regular arm mount. Therefore, it can be a concern for vandalism or aesthetics. Top jamb application can be used with non-hold open or hold open arms.

Parallel Arm: Parallel arm mount is a push-side double lever arm application. The closer is installed on the push side of the door and the arm is mounted to a parallel arm adapter plate installed to the frame soffit. The arm is approximately parallel with the face of the door, eliminating the projection condition evident with regular arm and top jamb applications. Parallel arm is often preferred where aesthetics or vandalism are concerns. Parallel arm is less efficient than regular or top jamb mounts due to the geometry of the arm. Parallel arm application can be used with non-hold open or hold-open arms.

Barrier-free design is another consideration. The terms “universal design” and “barrier free” are often used interchangeably, meaning that the door is Americans With Disabilities Act compliant.

Door closers help control the environment, containing heating and cooling, within structures, and are therefore significant energy management tools. Additionally, they keep the door closed when not being transgressed.

For light-duty residential applications, the purpose of the door closer may be as simple as closing the door behind forgetful family members so children and pets don’t wander outside.

The goal is to always be sure a door’s movement is under control: under the control of the door closer while it is swinging, while it is closed and even while it is being opened. Gusts of wind ‘grabbing’ doors while being opened is a notable cause of injuries and damage to doors and frames.

Fire doors are also required to be latched under most conditions, and, of course, the door must be closed before it can be latched. A closed fire door mitigates the spread of smoke, and contains the spread of fire.

Common Issues

Poorly adjusted or faulty door closers generate service calls for the locksmith. They prevent users from opening the door in a normal fashion, or prevent the door from closing and latching. A faulty door closer will often allow the door to close too quickly and slam.

If the door closer is leaking the hydraulic fluid used in most door closers, the closer is not going to be able to be adjusted or operate properly. This is a safety hazard that needs to be addressed to prevent a potential for slip and fall, or even the inconvenience of getting the fluid on the door users.

A door closer will not work properly if the door closer or door closer arm is not securely mounted to the door and frame. Most surface-mount door closers use similar profiles and are to some extent, interchangeable.

Even though the purpose of both pneumatic and hydraulic door closers is the same, there are some differences between them. Usually, pneumatic closers are used for lighter doors. Hydraulic door closers are considered to be stronger, so they can be installed on heavier doors. However, they have one significant drawback – hydraulic closers are vulnerable to high and low temperatures.

Recommended Door Closer Inspection

Check to see if the door has a label. If the door has a label, replace the door closer with a like model that does not require new holes. If new holes must be drilled, contact the local authority having jurisdiction (LAHJ) before starting work.

Be certain the door closes properly. There should not be any door warpage or loose-fitting hinge screws. If screws are loose and they will not tighten, replace them with longer and larger diameter screws, or repair the frame as needed.

Ensure that the door lock operates properly and the latch slides squarely into the strike opening.

When installing a door closer, read, understand, and follow the manufacturer’s instructions.

Measuring the door using a force gauge and observing the door closing are good ways to determine the functionality of the door closer and the condition of the other components on the door. It is also the first step towards adjusting the door closer.

Other factors include wind, stack pressure, condition of the door frame, hinges, friction between the door, frame and lock, lock alignment and weatherstripping. All these issues can prevent the door closer from working as required.

Tim O’Leary is an experienced security consultant and a regular contributor to Locksmith Ledger.