When I started my locksmith career almost 50 years ago, the shop that I worked at had four key machines in the shop and one in each of the three service vehicles. None of those machines was a dedicated “code machine,” because that type of machine still was rare and expensive. When we made residential or commercial keys from code, we used depth and space keys that we either made or purchased.

The closest thing that we had to an “automotive key machine” was an old Curtis machine that had a cutter that could handle steel keys. At that time, people would bring in steel blanks for some of the foreign cars. Steel Volkswagen keys were common, as were Mercedes-Benz and Volvo keys.

We had several Curtis “Clippers,” which could originate automotive keys by hand. The folks at Curtis did everything they could to discourage the use of the term “Clipper,” and I never could figure out why. Back then, every locksmith in the world called them “Clippers.” Eventually, Curtis came around, about the time that the tools started to fade away. I still carry a Curtis #14 “Clipper” in my truck and use it once or twice a month, typically on old General Motors cars and old VWs.

Enter Code Machines

As the differences between automotive keys and residential and commercial keys increased, key machines evolved as well. Eventually, dedicated automotive key machines started to appear, along with dedicated code machines that were used primarily for automotive keys.

The first dedicated code machine that I encountered was the HPC 1200. That machine soon swept through the market to the point that the current version, the Blitz, is advertised as “the standard of the industry.” I have used many HPC 1200 machines through the years, but I never have owned one.

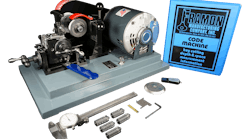

The code machine that I chose was the Framon #2, a manual machine. The reliability and ruggedness of the Framon machine as well as its ease of use and accuracy served me well for decades. (Those who believe that the Framon #2 is too complex never used one. After you understand the machine, it’s much faster, more accurate and easier to use than any card-based machine.) I still have mine, but it no longer lives in my truck, having been replaced by a computerized machine.

When side-milled, or sidewinder, keys started to appear in the North American market, they were considered an oddity, and few locksmiths bought the equipment necessary to duplicate these new keys. But as the number of vehicles equipped with side-milled keys increased, specialized machines for duplicating those keys came out. Prices of these machines dropped to where most locksmith shops had at least one machine for duplicating side-milled keys.

In 2009, GM adopted a side-milled lock system, and other domestic manufacturers went to a side-milled system as well. At that point, side-milled key duplicators and originators flooded the market. Many of the early machines were Chinese in origin with dubious patent issues and an almost total lack of support and parts. As the market matured, however, some innovative machines began to appear — and with full support networks through U.S. distributors.

It didn’t take long for computers to enter the key machine market as well. At first, computerized key machines relied on a separate computer for control. Now, most modern computerized key machines use an integrated tablet, which typically operates on the Google Android system. I now own two computerized code machines that can cut edge-milled and side-milled keys. Both of those machines also can be used to duplicate those keys.

Here's a look at a few of the automotive key machines available today.

Duplicators and Originators

As mentioned earlier, both electronic machines that I own can function as either a code machine or as a duplicator. But using these machines as a duplicator requires the machine to know the specifications for the lock system that the key operates with. Essentially, the machine decodes the original key and then produces a duplicate by code. The advantage of this system is that the duplicates often work better than the original, because the machine automatically compensates for wear in the original. The disadvantages are that it’s slow and if the original is badly worn or the spacing is off slightly, the machine will produce a “duplicate” that won’t work.

For those reasons, high-volume shops require dedicated duplicating machines to handle a large volume of keys in a short time. That said, a dedicated duplicating machine can be a big asset even if you don’t have a high-volume operation.

The other day I had to go to a camping area on the beach to replace a lost fob for a 2008 Toyota Prius. My computerized machine made a perfect code key from the code number on the door lock using a standard TR47 blank, but the e-key in the fob was too short for my computerized machine to handle. Fortunately, the duplicator in the truck saved me a trip back to civilization to cut the e-key.

Having a duplicator on hand is always a good idea.

The Express Duplicator from Framon

I personally love the innovative “no tools required” depth adjustment system, which allows me to quickly and easily change the depth adjustment. This really helps when you’re dealing with badly worn keys and allows you to make a “high duplicate” in seconds.

Unfortunately, this machine has been discontinued. Framon has a new duplicator in the works, but its release date isn’t certain. We expect it to have many of the features of the final Express, including the hardened key-guide, the titanium nitride-coated cutter and the wider carriage that will accommodate keys up to 4-3/8 inches in length.

More info: www.framon.com

Silca Speed 04X Series

There are four machines in the edge-milled Speed 04X series under the Silca brand in the Kaba Ilco universe:

- Speed 040 – Automatic or Manual Duplication

- Speed 044 – Semi-Automatic Duplication

- Speed 045 – Manual Duplication

- Speed 046 – Manual Duplication of flat keys

All of the machines share the same basic platform, which is designed for long life, safety and precision operation. All feature a depth tracer that has a micro-adjustment system that allows you to adjust the machine in increments of 0.00098 inches (0.025mm). With precision duplication like that, you should be able to duplicate pretty much anything that comes your way.

In addition, all Speed 04X machines feature four-sided, slotted vises that allow you to grip and tip-stop or shoulder-stop virtually any type of key blank. The vises are nickel-plated for long life and can be rotated easily simply by loosening the knob and turning the vise. The spacing between the vises is a generous 3-1/2 inches, which will accommodate today’s longer keys.

All cutters are titanium nitride-coated for long life, and mounting brackets are supplied with each machine for vehicle or workbench mounting. The large chip tray makes cleanup easy, and the large transparent chip shield and ergonomic design make the machine easy and safe to use.

More info: www.ilco.us

Keyline Easy Quattro

The Easy Quattro is a semi-automatic machine that can also be used as a manual machine. The internal workings have been designed to protect against electrical shorts caused by brass shavings. The motor, all of the wiring and switches are shielded to prevent brass shavings from contacting any electronic component. Other features aimed at safety, include a large, transparent shield that allows the operator to see what’s happening easily and safely, and an independent momentary contact switch is provided for the deburring brush. An automatic switch provides safe and sure starting only when the carriage is moved forward into the cutting position.

In addition, relays are used to prevent accidental overloads. Vises are equipped with slots that allow for tip-stop as well as shoulder-stop operation. The hardened key guide is easily adjustable for extremely precise calibration. The extra-wide spacing between the vises can accommodate extra-long keys or keys that have oversize heads.

More info: keyline-usa.com

Framon Sidewinder 2

This side-milled key machine is a manually operated duplicator capable of duplicating most side-milled keys quickly and accurately. The interchangeable and reversible vises will accommodate virtually all side-milled automotive keys, and the interchangeable high-speed cutters make short work of almost any key that you might encounter.

The Sidewinder 2 also originates side-milled keys and doesn’t use a computer in any way to cut these keys from code. Instead, the X and Y axis movements of the vise are controlled by two “code rods” located below the carriage. Different sets of code rods allow the user to cut different types of keys from code. The machine is shipped with rod sets for the Honda and VW/Porsche/Audi side-milled systems. Additional rod sets are available for the following side-milled systems:

- BMW four-track

- GM flip-key/Saturn Astra

- Hyundai/Kia

- Infiniti Q45 four-track

- Mercedes four-track

- Saab two-track

- Subaru four-track

- Toyota/Lexus

More info: www.framon.com

Code Machines

This article can’t cover all the code machines on the market; there are simply too many choices. That’s a good thing for locksmiths. As an automotive locksmith, you’re able to choose a machine that fits your demands. But on the downside, all those machines must go somewhere, and now there seems to be a glut of machines on the market.

As I did my research for this article, the bots used by various search engines decided that I was interested in buying a code machine. Now, when I open a browser or go to a social media site, I’m inundated by ads for various key machines, including many high-end code machines. Some of the ads are from locksmith distributors, but many are from mainstream retailers, such as Walmart, Best Buy and Home Depot. On the ads that I checked out, the machines were available only online and not in stores. But it still gives me the creeps to know that manufacturers that we’re supposed to trust will sell the tools of our trade to anyone.

With all of that in mind, I limited my discussion of code machines to just a few that either are relatively new or, in my opinion, have something special to offer to automotive locksmiths.

The Triton from Lock Labs

The people behind the Triton have worked hard to give it the capability to cut virtually any key, including single-sided keys, double-sided keys, side-milled keys and even tubular keys! At first glance you might notice features and parts that are similar to other machines, but a closer look reveals that even the familiar-looking components have been modified and improved to provide a smoothly working system designed by locksmiths for locksmiths.

The software is proprietary to the Triton and includes an onboard code system, complete with “fill” functions that will save you time by not having to consult other sources of data in the process of creating a working key. The software features free lifetime updates and constantly is improved based on feedback from actual users.

One of the features of the original software resulted in all keys being cut in a “laser cut” style where one cut transitions smoothly into the next. This is an efficient way to cut a key from a mechanical point of view, but it results in a key that looks a little strange to the customer and is more difficult for locksmiths to decode visually. As a result of feedback from users, the machine now supports the “laser cut” and “plunge cut” styles of key cutting. (This software update should have been released by the time this article went to print.)

Tech support is free for registered users, U.S.-based and staffed by knowledgeable U.S. locksmiths. Parts and service also available are in the United States, which is a big improvement over some of the other machines out there.

More info: www.tritonkeymachine.com

The Futura Pro from Silca / Ilco

The Futura Pro was introduced in 2016 and is the updated version of the original Futura, which has expanded to an entire line of key machines. The Futura Pro is another machine designed to do it all. It can cut almost all automotive keys, including single-sided keys, double-sided keys, side-milled keys, tubular keys, Tibbe keys, dimple-cut keys and even most residential or commercial keys.

The Futura Pro has two separate cutting stations. One uses a more or less traditional cutting wheel, while the other uses a carbide milling cutter. The Futura Pro is operated by a tablet that’s connected to the machine by Wi-Fi, so it can be mounted on the machine or used as a hand-held device.

The Futura Pro can be used for originating or duplicating keys. In duplication mode, it features an optical reader that allows you to duplicate an edge-cut key even if the specifications for the key aren’t in the machine’s database. The clamps on both cutting stations are multisided, which gives you options for holding virtually any key securely for cutting.

The machine database provides the user with access to Kreate-A-Key/Instacode for onboard code retrieval, including “fill” functions. Database software is updated free for six months after purchase, but after that requires a subscription. Updates to the machine operating system are always free to registered owners.

More info: www.ilco.us

The CONDOR XC-MINI PLUS from Xhorse

The CONDOR XC-MINI PLUS is a third-generation machine. I purchased the second-generation CONDOR XC Mini machine direct from China in 2013 when an overnight 80% pay cut forced me to prove that those who teach can sometimes do.

The XC-MINI PLUS is essentially a robotic key machine. There’s no way to use the machine in a “manual” mode, and if the specs for a particular key aren’t in the software, you won’t be able to use the machine on that system, even to duplicate a key. The machine is controlled by a touchscreen tablet built into the top of the machine. The tablet is hinged at the bottom, which allows you to tilt it to a comfortable viewing angle. This feature is the most obvious difference between the second- and third-generation machines. On the second-generation machine, the tablet was in a fixed position.

Most of the functions are intuitive, but you’ll have to study the literature provided with the machine to load updated software and customize the software. Software updates are free to registered users and accomplished by connecting the machine to an internet-connected computer by way of a USB cable.

The basic package includes a starter set of cutters and guides and two vises. (An optional third vise for Tibbe keys is available.) The M2 vise used for side-milled keys has four different sides and rotates smoothly on its support, so you can change from one gripping choice to another quickly. The M1 vise for edge-cut keys has only one gripping choice, but it seems to work well in most cases. But it isn’t capable of handling single-sided keys.

The machine has an extensive library of lock system specifications as well as codes. In most cases, you can cut a key directly from code by entering the key code into the machine. These features are updated periodically, so you’ll have to update your machine to stay current.

More info: www.americankeysupply.com and mwkeyless.org.

Steve Young has been a locksmith since 1973 and has trained and taught locksmiths since 1988. He is a frequent contributor to Locksmith Ledger.