When wired devices, such as key switches, window foil and push bars, came into use, wire transfers began to be mounted onto the door so wires could pass from the frame to the moving door.

The earliest power transfer I recall was the door loop. It was literally a pair of wires that looped from the door frame to the door, and door loops were problematical. The wire would be flexed every time the door opened and closed, and the wear caused power to become intermittent or cease. Early door loops looked unattractive, failed to protect the wires, were subject to vandalism and became snagged on things that passed through the door.

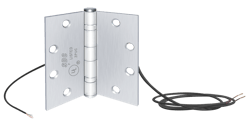

Electric hinges, referred to also as electrified or power-transfer hinges (PTH), were a big improvement as a way to transfer power from the frame to the lock.

For power-transfer applications, at least three hinges are used, and the center, nonload-bearing hinge is the power-transfer hinge.

For outswinging doors where hinges will be on the exterior of the opening, removing the hinge pins allows the door to be removed from the opening, so hinges are designed so the pins aren’t removable.

Wired pivots are used for aesthetics and on applications where the door might be subject to abuse. I’ve used wired pivots on storefront-type doors where we wanted to protect the hardware and wiring from vandalism, while providing an essentially invisible installation.

Wired Continuous Geared Hinge

Wired continuous geared hinges provide all the features of hinges and pivots, with a few advantages.

If you upgrade a door to electronic access control (EAC), wired continuous hinges are an option. In these hinges, most of the hinge is mechanical, and a small section of the hinge that’s mounted separately contains the wiring. Repairing or replacing a defective wired continuous hinge, thus, is relatively easy, and the door doesn’t have to be removed or its use suspended while the door is being repaired (except for when wiring and final installation is performed).

We use continuous hinges on doors where conventional hinges and pivots aren’t suitable. For example, if a standard butt hinge no longer tightens properly into its mortise, there might be concealed damage. On older buildings, I’ve worked on doors that actually were held together by layers of paint.

Any door that badly compromised is dangerous, because it might impede egress during an emergency and doesn’t provide security to the premises.

Conductors

Typical wired hinges use several small-diameter conductors made of woven wires and a fire-resistant fumeless coating. Performing the splicing and connections to PTH wire is different from most wiring and might require a few tools and practice to master. I use solder and b-caps.

Plug-and-play modular connectors are offered by hinge manufacturers to simplify and speed up the installation. After you have made the transition from the delicate hinge conductors to more-robust conventional wires, the task becomes more manageable.

Power-Transfer Choices

When determining the best power-transfer device for your application, answer the following questions:

1. What type of door is at the opening? The type of door can help you to anticipate the degree of difficulty of the installation.

A solid-core door represents a challenge to get conductors from the hinge side to the lock location (the latch edge).

Hollow metal doors aren’t exactly hollow. Bracing and internal intumescent material might be inside the door, which will complicate installing the wire. Drilling a fire-rated door could affect the rating.

Aluminum glass storefront doors and frameless herculite doors require special treatment to wire them.

2. What is being wired to the door?

Devices installed in doors typically are switches or sensors, electric-locking or latch-retracting solenoids, or electromagnetic devices.

The duty cycle and current draw will control the diameter and number of conductors transferring between the frame and the door.

Some devices require power or a connection only while the door is closed. This would include fail-secure locksets that must energize the lockset while the door is closed to allow the lever to become functional and enable the door to be opened.

Other types of locks require continuous power regardless of door position to ensure smooth operation. An example would be door-mounted electromagnets or exit devices that use latch retraction.

Interrupting power might result in latch-syncing issues or prevent the door from closing and latching. Many electronic devices don’t operate well in environments where power is interrupted frequently.

The type of device also will determine the power required to be carried on the transfer wires as part of a switching circuit or to operate the lock.

If you service an existing locking system, you should conform to the original locking system circuit design when considering replacing the power-transfer device, unless the problems with the door system points to a design error with regards to the power-transfer product specified.

If you upgrade to a different lock or system, it also might require rethinking the power-transfer hardware.

Troubleshooting

In the case of wired power transfers, the wire that passes through the door hinge is flexed and stressed during every door operation. Eventually, it will require replacement.

So installing or revisiting an electric power-transfer installation often is necessary, and you have to assess all the variables when you plan and price the repair or upgrade.

If a door already has electrification, how does that affect a potential hinge upgrade or replacement? This depends on the type of locking device on the door. Check for any visible signs of damage or abuse to the door or power transfer.

Before you dismantle the door, determine whether the problem is in the lock, the EAC system, the associated building wiring or the power transfer itself. Worn internal wires in a power transfer are a common point of failure.

Inspect the connections between the power-transfer wires and the lock and premises wiring. Test for continuity of each conductor, shorts between conductors or between conductors and ground. Because the wires pass through a metal hinge, they’re prone to shorts to ground, which might be overlooked.

With your multimeter connected to the power-transfer wires, move the door to flex the conductors and look for fluctuations in conductivity. If so, find a power-transfer product better suited for the door.

Marray Q&A

Marray is a well-established supplier of power transfers and installation tools. Locksmith Ledger spoke with Raymond Zehrung, president of Marray, about power transfer.

Raymond Zehrung: The strength is that the power and control wires are embedded into the hinge material, thereby making tampering difficult. Also, using concealed wire transfers doesn’t leave any noticeable modifications to the door or frame, should the door be tasked for mechanical-only opening. In other words, the hardware can be removed, used again and again in other doors, and the door that was modified continues to operate as a solid or hollow door, with an original look.

LL: Are electric hinges and pivots essentially the same thing?

Zehrung: Yes. They both pass power through a hinge; a pivot is essentially a hinging point. Pivots have different applications, such as aluminum storefront doors, heavy doors, doors that have aesthetic features, etc. Hinges are about 99% of the market, because they’re easy to mortise for, easy to install and more widely used because of costs.

The only advantage a 3/4 offset pivot provides is adjustment. However, when pivots are modified for wires, that adjustment screw in the center pivot is removed. This doesn’t negate the adjustment screw on the top and bottom pivots though. Standard butt hinges aren’t adjustable without fiddling with the mortise pocket.

LL: Are power-transfer hinges and pivots UL listed?

Zehrung: Not all power-transfer hinges or pivots are UL listed for fire doors. My company was the first to pay for a three-hour burn test, so all of our hinges and our 3/4 offset pivots are burn-tested. It’s important to ensure that any hinge that has been modified from the original ANSI 156 and NFPA 80 has received further testing to prove the modifications haven’t had a detrimental effect on the performance of the hinge or pivot in a listed fire assembly.

LL: Is a raceway tube allowed or required for wiring from the transfer to the device?

Zehrung: A tube isn’t required. A raceway is, except in aluminum and steel doors.

According to the NFPA 80 Standard, 1991 edition, only select field modifications can be performed on fire-listed assemblies, such as doors and frames. Removing core material by drilling a raceway or modifying the back plate material on a frame, wasn’t one of the accepted field modifications.

Marray developed the first tool designed specifically for drilling a raceway through a door. Over the years, we worked out a deal with Intertek Testing Services to accept a program we developed called the Perfect Raceway Program. This program is now an Intertek IQP, and under the direction and training of Intertek, qualified personnel can drill a raceway into a particle wood or mineral core door and apply a label to the door that has the Warnock Hersey Mark, showing the door was modified under Listing Agency Authority.

A raceway in a door is defined as negative space or, in common vernacular, a hole or removed material. Wood and mineral core doors don’t require any sleeve or tube inserted into the hole to meet requirements. I started my program with steel tubes that would be inserted, but it turns out that the steel tube would heat up and cause damage to the door during a fire. So it actually is more beneficial to not have anything inside the door, such as steel or metal. To get a wire from the hinge or transfer to the locking device, a raceway is necessary in wood and mineral core doors.

LL: Can you clarify what you mean that a tube isn’t required but a raceway is, except in aluminum and steel doors?

Zehrung: Steel and aluminum doors are often hollow, and the best way to wire those is to go over the top of the steel door and inside the channel of an aluminum door. Most aluminum doors are storefront doors, and as such, they have a glass insert, so a direct wire chase isn’t possible. Typically, the wire is run from the hinge, up over the top of the stile and down the latch side stile to the lock — same with a steel door. They typically are constructed with a 1.5-2.0 steel outer framed box, and the wires would be run from the back of the hinge, up the channel, over the top, down the channel to the lock — a big U-shape wire chase, so to speak.

Following are some of the power-transfer hinges on the market.

Marray Products

Marray’s specialty electrified swing clear hinges are made from scratch. Marray drills its hinges while the leaves are flat, places a steel cable into the hole and then bends the hinge. It then pulls out the cable with wires attached to it and essentially fishes wires around a corner. A casual observer won’t be able to tell the hinge has wires in it.

Marray hinges come only in heights of 4-1/2 and 5 inches.

Marray also offers other power-transfer devices, including the Kawneer-style center power-transfer pivot for storefront aluminum doors.

More info: www.marray.com

SDC hinges & power transfers

SDC offers concealed mortise devices, wired door transfer hinges and wireless power-transfer devices, all UL listed for three-hour fire-rated doors.

SDC’s heavy-duty electrified mortise power-transfer device provides a concealed and secure means of transferring electric lock and exit device power and signal wires from the frame to the door. The PTM series is aimed at heavy traffic and applications that require higher security to inhibit tampering and abuse.

SDC’s Wireless Power Transfer Devices use a radio frequency (RF) transmitter to send energy wirelessly across the door gap to an RF receiver that converts the energy to DC voltage to power electrified locks and latches. Retrofitting electrified locks into openings that have wood doors is simpler and less time-consuming, because core-drilling the door isn’t required. The WPT’s RF technology also allows for the transfer of latchbolt monitoring, request to exit or data signals.

More info: www.sdcsecurity.com

Command Access Concealed Door Loop

The Command Access Concealed Door Loop (CDL) is a low-cost method of transferring low-voltage power from the door frame to the locking device. The CDL slides into the door or frame, which makes it concealed when the door is closed.

The CDL is designed for continuous- and butt hinge applications that are full mortise, half mortise or half surface and have a standard throw. They’re an option where electronic transfer hinges are cost-prohibitive and surface door loops aren’t desired.

More info: www.commandaccess.com

ASSA ABLOY Architectural Door Accessories

ASSA ABLOY brand McKinney offers the ElectroLynx series of electrified hinges and power-transfer devices and cables for a universal quick-connect system that simplifies the electrification of the door opening. There are options for butt hinges and aluminum continuous geared hinges.

More info: www.assaabloyarchitecturaldooraccessories.us

ABH hinges

Architectural Builders Hardware Manufacturing (ABH) offers a wide assortment of power-transfer hardware, including geared hinges, power-transfer knuckles and pivots, including the E0519 Electrified Pocket Pivot with optional EZ Connect Molex Connectors for installation ease.

ABH also offers the EA Accessible Through-Wire (ATW) concealed geared continuous hinge. This hinge has no cuts or panels to compromise its performance or integrity. Simply remove the cover plate, access the recessed wires and make your repair.

ABH geared continuous hinges can be prepared for easy-access electric through-wires to provide continuous current.

More info: www.abhmanufacturing.com

Hager concealed loop

Hager’s concealed mortise power-transfer loop provides a concealed and secure means of transferring electric lock and exit device power and signal wires from the frame to the door. It’s recommended for use with hollow metal and aluminum frames. The all-metal design provides weather and tamper resistance when the door is open or closed.

The removable transfer allows the door to be serviced easily without removing the door from the opening. It isn’t intended for center-hung door applications.

More info: www.hagerco.com

SELECT Products ATW hinges

The SELECT Accessible Through-Wire (ATW) electrically modified concealed hinge’s fully integrated design lets you access a wire problem and make your repair in less than five minutes.

The design protects the ultraflexible 22-gauge through-wires so they last longer.

Select incorporated Molex connectors to speed up your hinge installations, too. Choose between four-pin, eight-pin or 12-pin connectors. Extra-long leads are available.

More info: www.select-hinges.com

Tim O’Leary is an experienced security consultant and a regular contributor to Locksmith Ledger.