Specifying electrical locking devices for exterior gates requires that attention be paid to details that are somewhat unique to this type of application. I think back to many gate lock installations I’ve done over the years, and each one was in some way unique.

To my way of thinking, gate locks are not a one-size-fits-all type of project. My experiences with gates has included commercial parking control gates, perimeter vehicle and pedestrian security gates, swimming pool enclosures for gated communities and condos, athletic facilities and estate driveway gates.

This time the gate was a residential vehicle gate on an operator. The first time I saw the gate, it was not working and badly neglected. The gate posts were solid, but the gate itself was constructed of wood, and weighed several hundred pounds. It was collapsing under its own weight. I replaced it with a cattle gate made of galvanized steel which was much lighter. I used two pipe gate hinges; not fancy, but very durable and inexpensive.

Manual/closer or operator: This gate was connected to a gate operator. Although the gate would be primarily used by residents coming and going, pedestrians would also use the gate. With the gate operator arm connected to the gate, the gate would not move freely, but did move enough for an individual to slip through which was unacceptable to the homeowners.

There are manual gate locks, or locks which are both manually (mechanically) and electrically controllable, but I decided to use an electromagnetic lock, which cannot be controlled mechanically, only electrically.

Unfortunately maglocks were sold as being extremely easy to install, so individuals without skills or interested in performing professional workmanlike installations were putting in maglocks without regard for safety and reliability, and code officials reacted by outlawing them in many jurisdictions. This has changed, but there are still many codes and guidelines that must be complied with when installing electromagnetic locks.

Below are some of the considerations:

Weight/condition of gate: Heavy wooden gates look nice but if they are vehicle width, there are maintenance problems because of the weight.

Duty cycle: Residential gates will get only a fraction of the usage of a commercial parking gate. Also there are safety codes associated with gates. Typically gate operators have integral sensors which ostensibly prevent injuries to people or damage to vehicles. Br mindful of the liabilities involved with working on gate operators.

Environment: Weather has a lot to do with your installations. Adverse low temperatures, moisture, snow and ice will have impact on your equipment.

Gate construction: Just like with doors, you cannot expect adding electronics to magically resolve existing issues with a damaged gate.

Mounting options: Gate hinges and other accessories such as gate wheels can be troublesome and difficult to source out and install. IMHO rehabilitating old worn gates will usually be a losing proposition.

Alignment: When installing accessories like maglocks, sloppy gates can pose challenges that even a maglock cannot overcome. The gate has to be able to return to a closed position with rather accurate three-axis alignment; otherwise it will not establish a bond and therefore will not be properly secure

Supplying power/interfacing/wiring: You see a lot of solar powered gate operators out there. Do a little research and you will learn that these systems rely on large batteries which are supposed to trickle charge quickly enough to be ready for the next gate operation. Connecting a lot of electronics which draws too much idle current will prevent the batteries from ever properly charging. Line voltage is better, and if you are running cable, run low voltage spare cables for possibly security, video, and intercoms. Gates are often located out of range for many of the ‘wireless wonders’ you see advertised.

Monitoring (bonded/gate status): It is a small upcharge to use a lock and a sensor on the gate for the additional convenience and security they will enable you to provide.

BEA Gatelocks

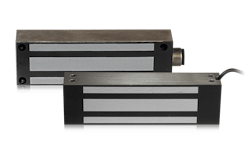

BEA’s UL Listed Gatelocks are designed to withstand the elements, featuring a stainless steel exterior and NEMA 4 enclosure to protect internal electronics. Customers like that the product is UL Listed as it adds credibility to the product and the dealer.

This lock is husky, and ought to hold up well and lock securely for years to come. With the inherent looseness associated with exterior fences and gates, maglocks are somewhat forgiving and will continue to grab if conditions change.

The BEA 10GL1200R’s weather-resistant construction makes it ideal for industrial gate and exterior door applications.

With a holding force of 1,200 lbs, the Gatelock is available in both a front mount model for sliding gates and a side mount model for swinging doors/gates. These locks include a built-in lock status sensor with an output relay. The front-mount model comes with a 3/4 inch male NPS threaded conduit fitting. It comes with built-in remote lock status sensor with an output relay.

Additional features include:

- Input Voltage: 12 / 24 VDC (UL Listed power supply recommended)

- Current Draw: 500 mA @ 12 VDC; 250 mA @ 24 VDC

- Relay Switch: 250 mA @ 12 VDC; 125 mA @ 24 VDC

- Dimensions : 8.75 in (W) × 2.50 in (H) × 1.625 in (D)

- Material: Stainless Steel

- Cable Specifications: 24 AWG 7-conductor cable, 3.5 ft

- Norm Conformance: UL and CUL, ANSI 156.10, NEMA 4 / IP65

- Conduit Fitting (10GL1200R ONLY): ¾ inch NPS conduit fitting, 14 threads per inch

More Info: www.beainc.com/en

SDC GL160/GL260 GateLok™

The SDC GL160/ 260 Series GateLok™ is designed to provide access control and remote locking and unlocking capability for manual or automatic chain link, tubular steel and wrought iron sliding or swinging gates.

SDC GateLoks™ may be unlocked by an access control and remote control. Some models also include a built-in keyswitch. SDC promotes this lock as higher security than electromagnetic locks.

The device uses a bolt which engages a locking tongue. Therefore the gate and gate post must be solid and stationary to assure proper alignment is maintained. A built-in sensor in the lock controls that the bolt will only extend into the tongue when the tongue and bolt are properly aligned.

The GL260MRA GateLok™ may be unlocked by an access control, remote control and built-in mechanical key. The mechanical key is for momentary override and does not maintain a sustained unlocked mode. Mechanical key retracts the bolt even without DC power.

Features:

- Solid Stainless Steel 0.625" Diameter Locking Bolt

- Continuous Duty Operation

- Low Current Draw

- Auto Relock Switch

- Heavy Gauge 0.125"

- Weather Sealed Steel Housing

- Access Control Compatible

- Designed for 3” Fence Post and 2” Gate Post and are Adaptable for Smaller Sizes

- Standard adjustable Auto Relock Switch keeps the bolt retracted until the gate is in the closed position.

*Note: GL260A and GL263A cannot be unlocked without DC power

More Info: www.sdcsecurity.com

Securitron GL1 Gate Lock

The heavy duty GL1 Electromechanical Gate Lock provides weather-resistant access control for a wide range of gate applications. I’ve used them outdoor pedestrian gates and indoors for tool cribs. A mechanical latch provides the impressive holding force rating.

The GL1 provides 2000 pounds of holding force for electrical and manually operated indoor or outdoor gates where preload is a concern, ideal for swinging or sliding gates and vehicle, pedestrian, or stock gate access control.

Specifications

- Holding Force: 2000lbs [907kg]

- Dimensions: 2-3/4"L x 7-1/4"W x 3-1/4"D

- Electrical:

- -12 Volts Initial (Peak): (~1.0 sec.) @ 870mA - Reduced: 290mA Power

- Consumption: 3.5 Watts

- -24 Volts Initial (Peak): (~1.0 sec.) @ 720mA - Reduced: 170mA Power

- Consumption: 4.1 Watts

- Operating temperature: -58 to +167F [-50 to +75C] (Indoor or outdoor use)

- Operates under preload up to 100lbs

- Automatic dual voltage - no field adjustment required

- Accepts a standard mortise cylinder with Adams Rite MS cam for manual key override (not included, see spacer guide below)

- Self-aligning receiver (+/- 1/2" horizontally) helps compensate for gate misalignment and sag

- Tamper resistant cast housing

- Optional latch status monitor

- Surface mount

- MagnaCare® lifetime replacement, no fault warranty

More Info: www.assaabloyesh.com