Within days after the introduction of the first vehicle equipped with locking doors, I suspect that someone locked the keys inside the vehicle. As I tell my customers who are locked out of their vehicles, “There are two kinds of people: those who have locked their keys in a car and those who lie about it.” It’s just something that happens — usually at the worst possible time.

As an automotive locksmith, it’s my job to solve those problems. Unfortunately, too many people believe that unlocking cars is all we do, when it’s actually only a small part of what we do. And as irritated as the customer is about being locked out, we’re usually more irritated, because we had to pull off a job or drive out to the boonies when we know we could be earning more money elsewhere. It’s sort of a no-win situation, but it comes with the territory. The best that we can do is do the job courteously, quickly and professionally, and then get back to work.

An emergency lockout is often the customers’ first interaction with a locksmith, and it’s a great opportunity to let people know that we do far more than unlock cars. I often offer to make the customer a free “mechanical key” while I’m there, which almost always helps to turn the conversation to the real work that we do. I get the opportunity to explain what a transponder is and why the mechanical key won’t start the vehicle. At the same time, I explain that I can provide and program transponder keys, smart keys and remotes for a fraction of what dealerships charge. Often, this comes as a complete surprise to the customer, and with luck they’ll remember me when they want my services or tell a friend.

The bottom line is you can think of unlocking vehicles in two ways: It can be a chore that you grudgingly must do, or it’s an opportunity to get paid for advertising your business. Word of mouth is the best kind of advertising there is, and you can’t buy it. But if you’re smart, you can earn it and make a little cash at the same time. All you must do is be courteous, professional and friendly. But above all, you must avoid damage to the vehicle. That’s where the professionalism comes in.

The Old Days

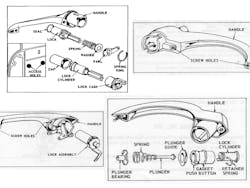

As I said, people have locked their keys in their cars for as long as there have been cars that have door locks. Early lock systems were rudimentary, and there were lots of ways to get around them. One of the most popular systems included the lock cylinder inside the push-button in the handle that was used to open the door from the outside. With these systems, the vehicle usually had to be locked by using the key from the outside, so it was difficult to lock the keys inside. But if the keys were lost, then the vehicle had to be unlocked before a new key could be made.

Basically, there was a tailpiece on the door lock that would release the latch when the button in the door handle was pushed. When the door was locked, the tailpiece would be rotated to a position where it no longer contacted the latch release. Pushing the button when the tailpiece was in that position wouldn’t open the door. But when the key rotated the tailpiece to the unlocked position, the tailpiece would contact the latch and open the door when the button was pushed. That seems like a crude system, but Ford actually used a similar system up into the 1980s on the rear doors of some vans.

At the time, the favorite method to defeat this type of system was to insert a flat piece of metal into the door and place it between the latch mechanism and the back of the push-button. When the button was pushed, the flat piece of metal would act as a replacement for the tailpiece and activate the latch release, which would open the door. The flat piece of metal soon became known as a Slim-Jim, and a legend was born.

As vehicles improved, so did the locking mechanisms. Soon, almost every U.S.-made vehicle used a push-button inside it to lock and unlock the door in addition to using the key. With this system, the vehicle could be locked and unlocked in two different ways. The inside lock button or the outside door lock could be used to lock or unlock the vehicle. This made it a lot easier to lock keys inside a vehicle.

Turning the key in the door lock or operating the inside lock button controlled the same lock component. This component was the tailpiece, also known as the “cam,” attached to the back of the door lock. This system is known today as a “lazy cam” system. When locked, by either the key or the inside lock button, the outside door handle was disabled. Operating the outside handle would have no effect on the door latch, and the door would remain closed. When the door was unlocked by the key or the inside lock button, the outside door handle would open the door.

The lazy cam on the back of the lock could be moved from the locked position to the unlocked position with relative ease by using the same flat piece of metal used on earlier vehicles — the Slim-Jim. Lazy-cam lock systems were in wide use up until the late 1970s, when insurance companies started to demand better locking mechanisms.

That was when most U.S. manufacturers went to a “rigid cam” lock system. The whole purpose was to stop Slim-Jims from working, and the new system did a relatively good job. In a rigid-cam system, the cam, or tailpiece, of the lock moves only when a key turns the lock. The part of the mechanism that controlled locking and unlocking of the latch was moved to inside the latch itself and suddenly became much more difficult to attack.

In a rigid-cam system, the vehicle typically can be unlocked in three different ways:

- By attacking the linkage that connects the inside lock control to the latch.

- By attacking the inside lock control directly.

- By picking the lock.

Most locksmiths at the time chose to attack the linkage between the latch and the inside lock control. Sometimes a Slim-Jim could be used for this, but its effectiveness was reduced dramatically. As time passed, manufacturers added guards and routed the linkage rods to make attacking them difficult. To deal with these increasingly difficult-to-attack linkages, many car-opening tool manufacturers introduced “bent-wire tools” to reach around or avoid guards and attack linkage rods.

Others came up with ways to attack the inside lock control in more convoluted ways. Lots of tools were introduced that went into the door and then came back up inside the passenger compartment to attack the lock control directly. These tools became known generically as “over and under tools.” The big problem with these tools was that after they were inserted into the door, they were almost impossible to remove until the vehicle was open. In some cases, they could get stuck in the door to the point that the door panel had to be removed to get the tool out, and in extreme cases, the tool could break the vehicle’s window.

In the early 2000s, the National Highway Traffic Safety Administration began to propose sweeping regulations for increased safety for passengers in side-impact and rollover collisions. The regulations went into effect in 2009, but auto manufacturers around the world knew they were coming and started to change vehicles as early as the 1990s. The first commercially available side-impact airbag system was introduced in 1995 on certain 1996 model-year Volvos.

Side-impact and rollover collision standards pretty much eliminated horizontal linkage rods because of the testing standards. In the side-impact tests, a vehicle had to survive a side-impact collision and roll over without the door coming open. It soon was discovered that linkage rods would bend in these situations and cause the doors to open. Generally, horizontal linkage rods were replaced with bicycle-style cables that had enough slack to prevent the door from opening during a collision. Some manufacturers went back to vertical linkages, which were protected by the frame of the door, and others went to electronic systems, but the majority of manufacturers adopted cables.

These new systems were almost impossible to attack by using traditional inside-the-door tools. This was what prompted Bob Womack and me to introduce the Jiffy-Jak Vehicle Entry System in 1999. Since then, many so-called long-reach tools have come on the market with varying degrees of success and sophistication. But the bottom line is that long-reach tools have become the overwhelming choice of locksmiths, tow-truck operators and, unfortunately, the general public. As I walk through parking lots, it seems that almost every other vehicle that I pass has some sort of damage that obviously was inflicted by the careless use of a long-reach tool. Some of the things that I have seen are appalling!

Moving Forward

In the second decade of the 21st century, vehicle entry hasn’t become any easier, and people haven’t become any better at keeping up with their keys. Lockouts occur every day, and we still are expected to have the solution. Between the side-impact safety measures and increased anti-theft requirements, vehicles are more difficult to unlock than ever before.

Picking the door lock simply isn’t an option for the general public and for most in the towing industry. Picking locks is what locksmiths are SUPPOSED to do, at least in the perception of the public. So that’s now the way I unlock at least 90% of the vehicles I get called out to unlock.

Many locksmiths resist the idea of picking vehicle door locks, because, in the past, it’s been difficult. Between the General Motors sidebar door locks of the distant past and the extra-wide keyways of the Ford locks, traditional lock-picking tools simply didn’t work well on vehicles. But that has changed radically for several reasons.

Mr. Li revolutionized automotive locksmithing when he introduced his Lishi 2-in-1 picks. Armed with his picks, I typically can pick open a vehicle faster than with a long-reach tool, such as my own Jiffy-Jak. And even if picking the lock takes a moment or two longer, it impresses the customer and virtually eliminates the possibility of damage to the vehicle.

Using the Lishi picks to unlock vehicles requires an investment in time and money. And to use them confidently, you have to spend time practicing. But after you know how to use one 2-in-1 pick, you basically know how to use them all.

Some people complain that Lishi tools are too fragile, but most of those who make that claim are the same ones who break regular lock picks. I have worked as a locksmith for 48 years, and I NEVER broke a pick while using it as a pick. (I have broken several while doing things that lock picks weren’t designed to do!) So far, I have broken one Lishi tool, but I had help with that.

A friend who is an excellent locksmith routinely manipulates safe locks open. He owns several Lishi 2-in-1 tools but never has grown comfortable with them. Through the years, I have done my share of manipulation, too, and I know that a great deal of skill and practice goes into being a good manipulator. As I have told my friend, learning to use a Lishi 2-in-1 pick doesn’t require anywhere near the amount of practice that manipulation does.

Another friend liked to say that picking locks is a “zero / hero” technique. If you get the job done quickly, you’re a hero. If it takes more than a minute or two, you’re a zero. The public has been convinced by movies and TV that lock-picking is fast. We all know that’s not necessarily true. That’s why I always have a backup plan. If I run into trouble picking open a vehicle, I’ll use a different technique.

When I get out of the truck to unlock a vehicle, I normally take four to six things with me:

1. A can of electrical contact cleaner, usually CRC, to use as a solvent to break up any hardened grease inside the lock

2. A paper towel or “red rag” to wipe off any excess solvent

3. A square of foam anti-fatigue mat to protect my knees

4. The appropriate Lishi 2-in-1 tool

5. A Post-it note and a pen

6. A magnetic flashlight if I work at night

Before I get out of the truck, I look up the direction to turn the door lock if I don’t already know. (For example, ALL Toyota and Lexus vehicles turn clockwise to unlock on the driver’s side door, counterclockwise on the passenger side door if equipped with a lock.) I might also bring a plug spinner if I’m unsure of the turn direction. A good rule of thumb is to ask the customer which way the key turns to unlock the door and then pick it in the opposite direction. That might sound like a joke, but my experience says otherwise.

It isn’t unusual to find a door lock that will pick easily in one direction but not at all in the opposite direction. When that happens, or if I accidentally pick the lock in the wrong direction, I’ll decode the lock and write the depths down on the Post-it note. I then might try the plug spinner to flip the lock into the correct position, but often that doesn’t work. But because I decoded the lock, I can cut a mechanical key and unlock the vehicle with the mechanical key. As I said, I then give the key to the customer and tell them to hide it on the outside of the vehicle in case they get locked out again. I typically suggest that they duct-tape the key to the back of the license plate, because a screwdriver typically is easier to find than a wire coat hanger.

If it takes longer to unlock the vehicle than I like, I’ll switch to another method, usually the Jiffy-Jak, to get the customer on their way quickly. I have great difficulty using the Jiffy-Jak or any other long-reach tool, because I live with torn rotator cuffs in both of my shoulders. I carry a folding stepstool in the van because I’m “vertically challenged,” and it helps me to see inside the vehicle better, but mostly it makes things easier on my shoulders.

Avoid Picking These Vehicles

Picking the door lock isn’t always the best choice. For instance, I never pick Lexus or Toyota vehicles that use side-milled keys. The split-tumbler design of those locks makes picking difficult, and it’s possible to damage the lock if you aren’t extremely careful.

The same goes for Honda and Acura vehicles that use the HON66 2-in-1 pick. If you have to pick one of those, be aware that you’ll have to pick it three times.

When you first pick it, the lock will turn just a few degrees until the split tumblers from one side drop into the slot for the split tumblers on the opposite side. You then have to pick those tumblers, which typically is easier than picking the entire lock, until the lock is free to turn the rest of the way. Then, when you turn the lock back, the same thing will happen again, and you have to pick the same tumblers again to get the lock back into the “key-pull” position. If you don’t pick everything back to the key-pull position, the key won’t go into the lock, and if the customer forces it, it can damage the lock.

Mercedes-Benz and BMW are other vehicles that present special problems with respect to lock-picking. On those, I typically use the High-Security Flip-Pick from Lockmasters. This is particularly true of the two-track Mercedes vehicles. I can and have picked those by using a Lishi tool, but if simply unlocking the vehicle is the goal, the Flip-Pick generally will do it quickly.

The same applies to Volkswagen, Audi and Porsche vehicles made before 2015 or so. On those vehicles, I pick the door lock by using a Goso pick, which is available from most distributors. That pick is amazing in the way it can pick those locks with little effort or skill involved. I recently had to make keys for a Porsche Panamera, and I was having trouble picking the door lock by using a Lishi 2-in-1 tool. I switched to the Goso pick and had the lock picked quickly. I then used the point of my Leatherman tool to hold the plug in the turned position while I removed the Goso pick and inserted the Lishi pick to decode the lock.

I have Lishi 2-in-1 picks for a lot of Hyundai and Kia vehicles, but those vehicles have so many different keyways, it’s daunting to stock all the options. As a rule, I typically can use a long-reach tool on Hyundais or Kias, but if it’s a high-end vehicle, such as a Genesis, or if it’s pouring down rain and the keys are locked in the trunk, I can pull a key code for less than $12 and be on my way quickly.

Speaking of rainy days, I always joked that “rainy days make people do stupid things with their keys.” While I was working on this article, we had several Northwest Florida all-day soakers in a row. I had two vehicles at the same time that had the keys locked in the trunk at a big soccer match. One was an almost new Lexus LS and the other was a BMW 3-series coupe. I used the Jiffy-Jak on both vehicles but still got soaked.

The bottom line is that if you offer vehicle-entry services for late-model vehicles, you have to be prepared for a lot of different options, but these days a Slim-Jim or bent-wire tool isn’t going to be good for much more than use as a back-scratcher.

Steve Young has been a locksmith since 1973 and has trained and taught locksmiths since 1988. Learn more at his website, www.autolockinfo.com.