As a locksmith, you might be tasked with repairing and adjusting vertical-rod exit devices already installed or adding them to new or existing doors.

Most of my own projects involve electronic access control, and my systems couldn’t work with malfunctioning door hardware, so I learned how to deal with all types of mechanical and electrified architectural devices.

Getting things to work properly is necessary to get paid and stay on good terms with the client. Performing professionally and reliably also goes a long way toward getting favorable treatment on the next bid and grabbing the nonwarranty change orders that inevitably occur.

Start with a dorm, and leave with the campus. Ah yes, memories!

A Few Basics

Exit devices, essentially universally recognized life-safety devices, are required by code at certain openings based on a room’s occupancy type and load. Getting the right exit devices can be critical for life safety and code compliance. You might have heard an exit device called a “crash bar,” a “touch pad,” a “push bar” or a “panic device.” Depending on who’s talking, they might be referring to the same thing or five completely different things.

The BHMA Certified Products Directory provides an up-to-date listing of all products that have been certified to ANSI/BHMA Standards. ANSI/BHMA A156.3 establishes requirements for exit devices and trim, automatic and self-latching flush bolts, removable mullions, coordinators and carry-open bars. Performance criteria include cycle, operational, strength, material evaluation and finish tests. To maintain BHMA Certified status, these products undergo periodic recertification.

There’s a listing of the definitions for the parts of exit devices. Some of the parts don’t have intuitive names, and being familiar with exit device vernacular is helpful.

There are 30 types of devices in the listing, which includes exit devices, automatic bolts, rim paddle devices and glass-door exit devices.

It’s interesting stuff, and in my opinion, anyone who works with exit devices should be familiar with this document. For more information, go to buildershardware.com.

Exit devices come in one of three types:

Rim: Rim exit devices have a latch that engages a strike that’s surface-mounted to the soffit of the frame. Rim exit devices are used primarily on single doors.

Mortise: Mortise devices have a mortise lock body that sits inside a pocket prepped in the side of the door. A standard 4-7/8-inch strike prep in the frame is used.

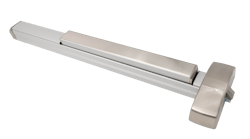

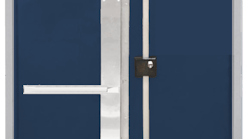

Vertical-rod exit devices: These exit devices can have latches at the top and bottom of the door or just one top latch. The bottom latch often isn’t desirable because that latch might drag on the floor and cause damage. The top latch engages a strike on the soffit of the frame’s head piece. Vertical rods are used at double doors when both doors are opened independently of one another.

Vertical-rod exit devices are available as surface-mounted vertical-rod (SVR) and concealed vertical-rod (CVR) models. Concealed vertical-rod devices also are available as concealed vertical cable.

Troubleshooting Tips

Before you begin any installation of a vertical-rod exit device, do your research. All hardware is well-supported by the manufacturer with details about determining the proper model and the details on fine adjustments. Review this information before you attempt an installation. Your distributor or the manufacturer likely can provide assistance.

When you assess the door and exit device that requires repair, carefully observe the entire opening before disassembly. Because panic hardware and the doors upon which they’re installed sustain much use and abuse, search the immediate vicinity of the door for parts or fasteners that might have become loose and fallen off the door.

Obviously, SVRs will be easier to inspect, and because they’re exposed on the outside of the door, the rods, latches and strikes are more likely to require service. CVRs almost always are used on metal doors, which makes inspection more difficult and repair not quite impossible. Have a borescope handy, and remember that gravity sometimes can work in your favor.

Trim and latches also are possible problem areas, and loose thresholds, dirt and rocks trapped between the edge of the door and the frame or debris in the threshold strike(s) easily can thwart the exit device’s proper operation.

If your exit device makes a scraping noise while the door closes or an arc is scribed into the vestibule floor, you likely are witnessing drag from the bottom rod hitting the floor. Fixing this is one of the most important adjustments that must be performed (and perhaps occasionally repeated) on SVR exit devices.

The top and bottom rods’ movement should be timed so when the exit device is pressed to release the upper latch, the door remains in the release mode after you stop pressing on the pushbar. The bottom rod then is pulled up so it doesn’t drag on the ground or make physical contact that would inhibit the door from swinging to the fully closed position.

Don’t forget the door closer. It also can fail or require adjustment. The upper latch is designed with a trigger, so when the door closes, the deadlatching trigger resets the rods so the bottom latch drops into the threshold strike and the upper latch is re-engaged into the upper strike. This locks the door until the next actuation.

A number of relatively simple adjustments are required for vertical-rod exit devices once in a while. Many facility guys are unaware of this, so when you arrive and immediately ask whether they hear a scraping noise, they might respond that they’re so used to it, they believe that it’s supposed to make that noise. After you’ve reset it, they recognize that the door is working properly again.

Tim O’Leary is an experienced security consultant and a regular contributor to Locksmith Ledger.