An exit device, also known as a panic bar, push bar or crash bar, is architectural hardware that opens a door when someone pushes a bar.

Although originally designed to prevent injuries and deaths at building exit doors, they now are used as the primary door opening mechanism in many commercial buildings, because they also provide convenience and accommodate individuals who have disabilities.

Exit devices often are referred to as crash bars, because that’s how people use them — by crashing into them with their bodies, forklifts, gurneys or whatever they’re carrying.

The reason the crash bar is there is so the door can be opened for egress without having to grip and turn a lever or knob. Operating it should be apparent enough so anyone can locate it and figure out how to unlatch it, even if the room were full of smoke.

Background

The first version of an exit device was patented in England in 1892, but the devastating fire at Chicago’s Iroquois Theater in 1903 inspired the development of the Von Duprin 88 exit device.

The capability of the device to save lives became realized more completely after building codes started to require that openings in buildings that were critical for occupant egress be outswinging and equipped with readily recognizable and simple-to-operate hardware. The exit device then was used extensively in schools, hospitals, theaters, public assembly buildings and houses of worship, among other applications.

Having a knowledge of exit devices and features available is helpful while specifying and making sales.

Types & Styles

Exit devices are available in a variety of types, styles and categories, and they can be mechanical or electronic and tied into an electronic access control (EAC) system. This article is concerned with mechanical exit devices.

The Builders Hardware Manufacturers Association (BHMA) divides exit devices into two groups: exit devices and fire exit hardware. The distinction pertains to features.

On an exit device, a dogging device allows the release bar to be locked down so the latch bolt remains retracted and the door remains unlocked. On fire exit hardware, which is labeled for use on fire doors, dogging devices aren’t permitted. That’s because fire doors must have an active latch.

When you inspect fire exit hardware, there should be a label indicating its applicability. A label on the fire door also should indicate that it’s a fire door and should have fire exit hardware, not just a standard exit device.

A fire-rated exit device must meet UL standards to receive the UL listing and must be labeled clearly as such.

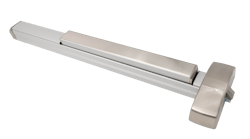

There are three basic styles of exit devices:

- The touchpad style is the most common style used for modern buildings and allows flexibility for electrification and other options.

- The crossbar style is often used when aesthetics dictate a minimal silhouette for glass doors or a vintage look.

- Recessed panic hardware reduces the projection of the hardware from the face of the door but requires a large cutout in the door and might limit the door material to hollow metal.

Exit Device Categories

Exit devices fall into three basic categories:

- Rim exit devices

- Vertical-rod exit devices

- Mortise exit devices

Rim exit devices. Single doors use a rim exit device. This single-point mechanism uses a spring-loaded latch — many have a Pullman-style bolt — to secure the door. This might incorporate a deadlatch feature. This feature, which is built into the lock, makes it so the lock can’t be manipulated into opening. Only a key or an inside knob or lever will retract the latch.

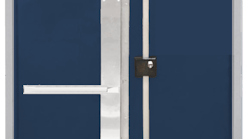

Vertical-rod exit devices. There are two styles of vertical-rod exit devices. The standard vertical-rod exit device is surface-mounted. There also is a concealed version, where the vertical rods and the latch mechanism(s) are installed within the door body. A vertical-cable exit device uses flexible cable instead of rods. Upgrades to existing door installations usually end up with surface-mounted rods.

In special situations, a Less Bottom Rod (LBR) installation might be necessary. Because only the top rod is securing the door, approval from the authority having jurisdiction (AHJ) is necessary for such an application. LBR installations are desired to make passage of wheelchairs and stretchers easier. An advanced type of vertical-rod exit device is a multiple-point lock, which means that more than a single latch point is employed. These locks use vertical rods and a rim exit device mechanism.

Locksmiths devised a method of providing multiple-point locking by adding pins into the hinges that brace the hinge edge of the door. This prevents bypassing the door by popping the hinge pins.

Mortise exit devices. A mortise exit device uses a bar to release a latching mortise lock. The mortise body usually is similar to that used by any other mortise lock. The exit device is surface-mounted on the door and interacts with the mortise case through a special cam or bar that activates to withdraw the latch. Nonfire-rated mortise exit devices can be equipped with dogging mechanisms.

Mortise exit device outside trim might consist of a lever or knob similar in appearance to a conventional mortise lever or knob and a keyed cylinder to control the locked position.

Follow the Code

Upgrading and repairing exit devices can be an important aspect of most locksmiths’ activities. Where exit devices are used largely is determined by the Building Codes. How the building or areas inside a building are used and the occupancy load are factors. Even so, there are discrepancies between the codes over what occupant load is required.

This highlights an important aspect of the codes. There’s more than one “Model Code” and they’re revised constantly. You as an installer have to be knowledgeable about what’s required in a particular structure in your jurisdiction.

I’ve worked on projects where more than one AHJ was involved, and they didn’t play well together, so you have to be flexible and knowledgeable about your options.

When on the job, in most cases exit devices are already on-site. They were specified at the time the building was built or the tenants took occupancy.

I rarely have had to remove an exit device, but when codes are upgraded or a change is made in a building’s walls, construction or use or there’s a reclassification of the occupancy type, additional exit devices might be required. (Required doesn’t mean the same thing as “allowed” in the world of codes.)

Doing the Work

A contractor often will use a locksmith to supply and install specialty architectural items, such as exit devices, because frequently there are issues associated with keying locks, adjusting doors for proper operation or making substitutions to the hardware schedule to accommodate a change order.

Exit devices are designed to be used and abused and continue to operate. They aren’t supposed to be abused while being installed, but I’ve encountered plenty that have been.

Many security pros don’t know how to work with exit devices in all their manifestations. A few do, and it pays off for them. It also could for you.

Here’s a roundup of possible mechanical options:

Yale 6000 Series

The Yale 6000 Series exit device can withstand the rigors of multifamily, retail, office and other commercial exits. The series includes a range of functions, including rim, mortise and vertical-rod configurations, and features smooth, quiet operation.

More info: www.yalecommercial.com

Arrow ED910 Series & PEC910 Series

The ED910 Series and PEC910 Series exit devices by ASSA ABLOY company Arrow are similar in function, yet different in form. The ED910 Series is aimed at everyday solutions, whereas the PEC910 Series features a one-piece design that has a permanent end cap, which makes it suited for high-traffic or high-vandalism areas. Both products are BHMA Grade 1 certified and designed to replace or upgrade existing devices.

More info: www.arrowlock.com

SECO-LARM SD-962AR-36G

The SD-962AR-36G has heavy-duty Grade 1 steel construction, is UL listed and appropriate for metal or wood doors up to 1-3/4 inches thick.

It has a separate deadlocking latch that prevents the use of credit cards or similar means to open the latch bolt.

More info: www.seco-larm.com

Securitech Auto-Bolt MAX

Securitech has brought its automatic multipoint locking to the exit device, either surface-mounted or concealed. The Auto-Bolt MAX series is aimed at high-traffic exits and is available in double-door applications. It provides up to five points of deadbolt locking protection. A single action of the touchbar retracts all bolts simultaneously, so it meets life-safety, accessibility and fire-code requirements.

More info: www.securitech.com

Detex Advantex Series

Detex’s Advantex line has all the types of exit devices.

In addition, the company’s online resources are some of the best in the security industry. Products are categorized by market (for example, retail, education, healthcare), with product descriptions and installation instructions, as well as other interesting, useful resources. Detex also provides terrific live tech support, which saves time and money on service calls.

More info: www.detex.com

Marks X-it exit devices

Marks X-it exit devices are aimed at panic and fire exit applications on standard (M9900) or narrow-stile (M8800) doors.

M9900 Panic Exit Devices are a heavy-duty, easily installed solution where high-quality panic and fire-listed hardware is necessary. The M8800 Narrow Stile Exit Device is designed for use on all types of narrow-stile single and double doors.

More info: marksusa.com

Precision Hardware APEX 2000 Series

The broad APEX 2000 Series by the dormakaba brand delivers functionality and dependability. The APEX 2000's durable construction allows it to withstand high traffic and high use on a regular basis and is aimed at healthcare and education buildings.

More info: www.precisionhardware.com

Tim O’Leary is an experienced security consultant and a regular contributor to Locksmith Ledger.