Selling the "right" hardware for a commercial or institutional job is dependent first and foremost upon meeting applicable Life Safety and building codes. If doors open to the public, they are generally considered the path of egress and must accommodate egress without prior knowledge. They also must meet Americans With Disabilities Act (ADA) requirements. If the opening is fire rated, additional restrictions apply. After all code requirements are understood, we can then begin to think about and discuss what the owner/end-user wants to do with the door.

Important: This article does not take into account specific installations for several reasons. The first is that different states and local governments adopt building codes at different times. In addition, the Local Authority Having Jurisdiction (LAHJ) or other authorities can provide a variance, consenting to lock hardware that is not normally permitted as specified. Remember, a variance is good only as long as the LAHJ believes it is in the best interest of the occupants.

Scenario 1: Non Fire-Rated Opening

A non-fire rated opening was chosen as our first scenario because it is the least complicated installation. A single pair of double inswinging doors provides access to a storage room that is not available to the public. These doors open to a standard sized storage room that meets local and state building and fire codes. Be aware that local codes, which may vary by location, may determine space size.

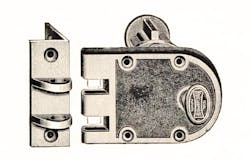

For this opening, we are not affected by ADA, as it is not public space. This increases our lock hardware choices beyond cylindrical locks, exit devices and mortise locks. For this opening, I selected a Jimmy Proof lock, pull handle and a cane bolt mounted onto the inactive door.

A cane bolt is an inverted "L" shaped metal rod used to secure an inactive door or gate. Cane bolts are available in a variety of materials including stainless steel or metal bolts that are either powder coated or galvanized. Lengths range from 12 inches to three feet or more. Alternatives to cane bolts include flush bolts and surface bolts.

To open the door, a door pull or handle should be installed that appears similar to existing door trim. If desired, a push plate can be installed onto the inside of the door.

Jimmy Proof locks, originally known as Segal locks, were developed by Samuel Segal in 1912. Segal, a New York City Police Officer saw a need to prevent thieves gaining access by "Jimmying" (spreading) the doorframe until the latch or bolt no longer contacted the strike plate. Jimmy Proof locks interlock the door and jamb together with deadlocking vertical bolts that move through the knuckles of the keeper (strike) and into the lock case.

Offering your customer additional protection such as door plates and door operators can provide added security for the building and added profit for your labors.

Since this is a storage room, door and frame protection can be installed to protect the opening from carts, etc. Doorplates are available up to 48" high and corner guards and U-channels are available to protect the frames.

Scenario 2: Fire Rated Opening

The pair of outswinging doors in this office building is fire rated. For this installation, new hollow metal, 3-hour fire rated doors were purchased and installed. For this interior application, 18 gauge doors were ordered. The occupancy load, more than 50 persons, requires exit devices as the lock mechanism. Fire doors are required to be self closing and positive latching. The doors were ordered with exit device and door closer reinforcement.

Blocking is additional metal welded to the door in the area of the door closer or lock. The standard door closer reinforcement is to 14 gauge and 12 gauge for locks. This ensures there is sufficient metal for securing the device and sufficient strength that the door can withstand normal use and abuse. If there is no “blocking,” it is important to have a general understanding of the thickness of the door face. If the thickness is not sufficient, at least threads, sex nuts and bolts should be used to secure the hardware to the door.

The hardware chosen for this opening and installed onto the door must be fire rated and carry the appropriate fire label. Fire door assemblies have one of five ratings: 3 hour, 1 ½ hour, 1 hour, 45 minutes and 20 minutes. Door hardware requires the same fire rating designation as the door. Fire rated door hardware includes door closers, hinges/pivots, locks as well as door viewers, astragals, door coordinators and protection plates (over 16" tall), etc.

The rating of the door hardware must at a minimum be the same as the rating of the door. If the opening requires a 20-minute door, each hardware component must be rated at least 20 minutes.

For this application, there are three options for the exit devices:

1. Surface or concealed vertical rod

2. Surface or concealed vertical rod less bottom rod (LBR)

3. Rim exit devices incorporating a fire rated removable or fixed mullion.

Some building owners and end-users do not like a mullion placed into the door opening. However, two rim exit devices using a mullion for the strike plates provide a higher level of security and require less maintenance than two vertical rod exit devices.

Note: Fire rated door must be factory prepped for less bottom rod exit devices. The exit devices cannot be legally converted in the field by removing the bottom rods.

Architects like concealed vertical rod exit devices. The secured side of the door is "clean" with no exposed rods or latches. However, locksmiths like surface vertical rod exit devices because they are easier to service. A concealed vertical rod exit device-equipped door in a low ceiling environment requires the door to be pulled down for service.

The advantage of the vertical top rod-only exit device is it eliminates the trip hazard on floor. The hazard is from the floor-mounted strike. For fire rated openings, top rod-only vertical rod exit devices are required to have an auxiliary fire deadlatching assembly (thermal pin) factory installed into the swing edge of each door.

For fire door installations, surface applied intumescent fire gaskets are designed to expand and fill the gap between the doors and the jamb. Some intumescent gasket materials can also act as smoke and draft gasketing.

Non-fire rated protective plates can be installed onto the fire rated door as long as they are not higher than 16 inches and installed using the proper method of attachment. Up to a 48-inch high protective plate can be installed if the plate is fire rated.

Scenario 3: Grade 1, Non-Fire Rated

The pair of out swinging doors in this office building is not fire rated. The door can be hollow metal or wood. Even though the opening is not fire rated, the door hardware must be Grade 1.

For this application, the occupant load is 50 or less, which permits the use of a mortise lock. If the occupancy load was more than 50, the locking mechanism must be exit devices. If the occupancy load is more than 15 and less than 50, both doors must be active, which means each door must have an operable locking mechanism and a fixed position strike plate. If the occupancy load is 15 or less, there can be one active and one inactive door. The inactive door can be equipped with the strike plate.

For the purpose of this article, the occupancy load is 15 or less, permitting a mortise lock on the active door. To accommodate code, the mortise lock will be equipped with lever trim that has a return within ½ inch of the door face. The return accommodates CSFM and other codes to prevent fire hoses being caught within the lever return.

The classic Cremone Bolt consists of a pair of movable rods, operated by a centralized knob/lever mechanism. Rotating the mechanism extends the rods into the header and sill, securing the door. When the rods are retracted, the inactive door can be opened. An alternative to the Cremone Bolt is flush bolts and surface bolts.

The exterior side of the inactive door was equipped with dummy trim to match the active door lock. There are no code issues having a strike plate that extends from the exterior of the inactive door.

For this opening, a power door operator can be installed in place of the door closer on the active door to provide access for those individuals requiring additional assistance.