One of the challenges facing locksmiths installing access control is providing the correct locking device for the application.

The electric locking device is perhaps the most important component in an access control system. The electric lock has to be reliable, and cannot compromise the safety and security of the opening.

How does the locksmith determine the best electronic locking device for a particular application? The steps are:

- Determine if the door is labeled, if it is subject to the life safety sections of the relevant building code(s) based on the site’s Occupancy classification.

- Find a locking device that will fit on the opening and retrofit to existing hardware on the door.

- Develop a design for power and auxiliary control to the locking device.

Key questions to answer include:

- How secure must the lock be?

- Should be failsafe or failsecure?

- Is the door a means of egress?

- Is the hardware going to be installed on an interior or exterior door? Will the door be subject to abuse or vandals?

- Do aesthetics matter?

- Is the opening fire rated?

- What type of mechanical lockset (mortise, cylindrical or rim) is used?

- Is the door swinging or sliding?

Also, make sure the door is in good condition before installing the lock. Check that it swings freely; the door closer works correctly and the door does not drag or interfere with the frame or saddle.

Three Problem Scenarios

When the subject of electric locking devices comes up, I think of three situations I have encountered during my tenure in the security industry. (Readers should feel free to submit their own experiences relating to electric locking hardware to the editor of the Locksmith Ledger, and we can compare notes in a future column.)

1. Mass marketing of electromagnetic locks and the improper deployment of electromagnetic locking systems resulted in the banning of their use. Initially maglocks were used only for specialized applications, and installed only by locksmiths. When maglocks were introduced into national distribution, their price went down and other trades such as alarm installers and electricians installed them as a quick fix locking solution. Some highly publicized tragedies resulted from entrapment due to maglocks, leading to restrictive codes or outright bans.

2. Early inexpensive electric strikes were destined to break, especially those used in multi-tenant housing where the main entry door was connected to each apartment’s intercom to allow buzzing people in. Building owners wanted the least expensive lock possible; the intercom installer complied, and then the callback started. Replacing these pot metal strikes was one of the first recurring revenue streams for the security industry.

3. Some electric locking solutions were easily bypassed. There was a perfectly secure opening until the access control installer rendered it less secure by either using the wrong lock, improperly installing it, or failing to provide ancilliary measures to prevent the lock from being bypassed.

The idea is we learn from our mistakes, isn’t it?

Our featured products offer solutions to many installation challenges, each product providing what is hoped is a unique set of benefits and features. Each product represents great new technologies from recognized manufacturers. The more experienced you are, and the more you know about the specifics of the opening and the application, the more you can refine your specification.

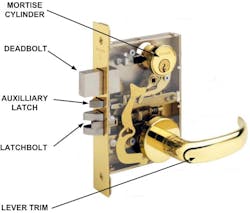

With regards to matching a strike to a mortise lock, several variables are cause to carefully consider which electric strike will work, or work best. These include the dimensional profile of the latchbolt, auxiliary latch and deadbolt. We hope the specifications and product descriptions help you in this regard.

HES 1006 Series Electric Strike

HES says the 1006 series is the strongest and most versatile electric strike available. Its dual interlocking plunger design and heavy duty stainless steel construction enable it to exceed every standard developed for electric strikes. It is tested to exceed 3,000 lbs static strength, 350 lbs dynamic strength, and factory tested to exceed 1 million operation cycles.

The 1006 will accommodate any lock designed to work with an ANSI 4 7/8” faceplate on metal or wood frames. There are 27 faceplate options and other accessories available.

The 1006 Series includes the following models.

1006CS - 1006 Complete Smart-Strike™:

Accommodates all cylindrical or mortise locksets for ANSI 4-7/8” strike plates, with or without a 1” deadbolt

Includes 1006 strike body, SMART Pac III™, five interchangeable faceplates and mounting hardware

1006CLB - 1006 Complete for Latchbolt Locks

Accommodates all cylindrical or mortise locksets for ANSI 4-7/8” strike plates with up to a ¾” latchbolt

Includes 1006 strike body, three faceplates and mounting hardware

1006CDB - 1006 Complete for Deadbolt Locks:

Accommodates all locksets for ANSI 4-7/8” strike plates with a 1” deadbolt

Includes 1006 strike body, two faceplates and mounting hardware

Listings, Approvals & Patents

UL 10C fire-rated, 3 hour single door (fail secure only)

UL 10C fire-rated, 1-1/2 hour double door (fail secure only)

CAN4-S104(ULC-S104) fire door conformant

ANSI A250.13-2003 windstorm listed

UL 1034, burglary-resistant listed

ANSI/BHMA A156.31, Grade 1

NFPA-252 fire door conformant

ASTM-E152 fire door conformant

MEA New York City accepted

Florida Building Code approved

Patents #6021038 & 6595564

Power Requirements

.45 Amps @ 12VDC continuous duty

.25 Amps @ 24VDC continuous duty

Standard Features

- Stainless steel construction

- Tamper resistant

- Fail secure (standard)

- Dual voltage 12 or 24VDC continuous duty

- Non-handed

- Internally mounted solenoid

- Accommodates up to 1" deadbolt

- Plug-in connector

- Full keeper shims for horizontal adjustment

- Trim enhancer

- Five-year limited warranty

Optional Features

- Fail Safe

- LBM - Latchbolt monitor

- LBSM - Latchbolt strike monitor

27 interchangeable faceplate options (monitor switches may not work with all faceplate options)

1000-102 - Rain guard

1006-103 - Full keeper shims

1000-104 - Lip extension trim adapter

1006-105 - Trim enhancer BLK (goof plate)

1006-109 - Trim adapter

1000-110 - Replacement strike plate

1000-130 - KD filler plate

For more information, contact your local locksmith distributor or HES, www.hesinnovations.com.

Effeff 8037 Strike Lock

The effeff 8037 electric strike with latch is used as an additional locking system, used for retrofitting on commercial doors (e.g. adding access control) and as a supplementary locking system for glass doors. It an ideal alternative to a holding magnet, small, strong and with low power consumption.

Features:

- Fail-unlocked

- Fail-locked optionally available

- Holding force 3,000 N / 670 lbs

- Easy installation

- Installation with L-bracket possible

- Installation on glass doors with additional adhesive panel and adhesive set

- Narrow housing

- Optional monitoring contact for door status

This strike is easy to install and installation is possible on both the hinge and non-hinge sides of the door. It can be installed on glass doors with additional adhesive panel and adhesive set

There is a horizontal adjustment option on the electric strike with optional L-bracket and vertical adjustment option on latch bolt mating component.

Fore more information, contact your local locksmith distributor or effeff USA, web site http://www.effeff.com.

Schlage ES6400 Electric Strike

The ES-6400 fire rated strike from Schlage combines strength and convenience in an “all in one” compact, easy-to-install design. The ES-6400 is UL listed for 1500 lb. static strength.

The unique design of the ES-6400 allows the installer to move the deadbolt keeper or plug and deadlatch ramp vertically to align with a wide variety of mortise locks with offset latches. Combined with a 1/8” horizontal adjustment, this provides a highly flexible design and eliminates the need for special face plates. A trim plate for frame cuts and a hands-free adhesive paper template are provided to simplify installation. Additional flexibility is provided by a “plug in” latch monitor switch that can be added in the field at any time after installation.

The power failure mode of the ES-6400 is fail secure only for fire rated openings. In a fail secure application, the door is normally locked without power. To unlock the door, power must be applied. The voltage of the ES-6400 is field-selectable 12 or 24 VDC and 12 to 24 VAC.

Vertical adjustment of the deadbolt keeper or deadlatch ramp allows for alignment with a wide variety of mortise locks with offset latches. It accommodates up to 1” deadbolt (Night-latch function only, bolt will not release). Up to 1/8” horizontal adjustment is possible for misaligned frames.

Features

- Vertical adjustment of the deadbolt keeper or deadlatch ramp allows for alignment with a wide variety of mortise locks with offset latches

- Accommodates 3/4” latch projection

- Centerline face plate included for centerline entry

- Heavy duty stainless steel construction

- Plug connectors are furnished for ease of installation and removal during strike servicing

- Non-handed design provides greater flexibility

- Tamper-resistant screws included

- Hex and security driver bit included

- Low current draw (0.19 amps @ 24 VDC)

- Unique solenoid design prevents keeper from heating up

- Trim plate included

- UL listed for 1500 lb. static strength, UL 1034 burglary-resistant listed & UL 10C 3 hour fire-rated (fail secure only)

Wiring Instructions: Use the appropriate wire harness supplied.

12V for 12VDC & 12-24VAC

24 for 24VDC only

Attach the red wire to (+) positive of the power supply. Attach the black wire to the (-) negative of the power supply.

If using AC power, polarity is not observed.

Note: If a suppression diode is required for access control, observe proper polarity.

Latch Monitor Wires:

Black = Common (C)

Blue =NormalClose (NC)

Orange =NormalOpen (NO)

For more information, contact your local locksmith distributor or Schlage, web site http://www.securitytechnologies.ingersollrand.com.

TRINE 4100 Electric Strike

Called “The One Box Solution for Cylindrical and Mortise Locks,” the Trine Access Technology 4100 electric strike contains the four most popular faceplate configurations (covering 90 percent or more of installations without deadbolts). This fire rated 4100 will minimize installing and specifying difficulties of the past.

The Trine 4100 adapts to multiple voltages (12/24 DC and 12-24 AC), features a low profile (1-3/8”) backset and stainless steel trim skirt to allow for maximum flexibility.

The 1 – 3/8” shallow backset allows the #4100 to be used in 2" fire rated frames with 1/2" sheetrock ingress, as well as tight spots in general.

ANSI Grade 1 is met by its 3,250 lbs. holding force and 1,000,000+ life cycles which allow it to be used in the most demanding environments. It is 3 hour Fire Rated WH and soon to be ETL Burglary Rated.

The Trine 4100’s low current draw of .240 Amps at 12DC is ideal for PoE installations. The current draw of .114 Amps at 24DC allow for smaller power supplies in all installations.

Included in the one box solution are additional Torx® security screws and latch shims for compensating horizontal door play.

For more information, contact your local locksmith distributor or Trine, web site www.trineonline.com.

BEA Electromagnetic Gate Locks

Designed with a rugged stainless steel housing and conduit fitting, BEA’s electromagnetic locks are suited for indoor or outdoor sliding and swinging gates and high security doors.

The BEA 10GL1200R is the front mount model with conduit connection. The BEA 10GL1200S is the side mount model.

Features

- UL Listed.

- Built-in remote lock status sensor – ideal for remote monitoring

- Available in a front mount model with a ¾ inch male universal threaded conduit fitting and a side mount model for swinging doors and gates.

- No residual magnetism

- Field selectable 12 or 24 VDC

- Built-in surge protection

- UL and ULC Listed for use on fire rated doors for up to 1½ hours

- NEMA 4 certified

Dimensions (LxHxD): 8.75” x 2.5” x 1.625”

Stainless Steel housing

Input Voltage: 12-24 VDC

Current Draw: 500mA@ 12VDC; 250mA@24VDC

Contact Rating: 0,250A@12 or 24VDC

Rating Cable Spec: 24 AWG 7 Conductor @ 3.5’

For more information, contact your local locksmith distributor or BEA Inc., web site www.beasensors.com.