Everything You Ever Wanted To Know About Spindles from Progressive Hardware

A few years ago, a customer called me in a panic. He had a couple of installers working at a Federal building in Washington D.C. and they had a problem. This call was about several sets of period reproduction knobs and escutcheons they had manufactured and the installers had been provided with the wrong knob spindles. Several thousand dollars of hardware and two men were sitting idle. The foundry was on the West Coast; the installation was on the East Coast.

The problem was the mortise locks had not been examined properly. The knob spindles would not fit into the lock hubs. A couple of telephone conversations with the factory and the installers on site solved the problem. A small box of spindles was sent out NEXT DAY AIR, the job was completed. Total cost for the spindles, less than $100. Total cost for two men doing nothing for two days - you figure it out!

Progressive Hardware offers a complete catalog of products, yet we probably spend more time talking to customers about what kind of spindle to use than any other topic. So simple but so complicated. I cannot tell you what knob spindle to use in every lock in the country, but I might be able to help you to know what to look for in order to purchase the correct spindle.

During the last 100 years or so, lock manufacturers have come up with all sorts of ingenious ways to get a doorknob to work their mortised lock. Basically, you put a square rod into a square hole and turn the rod; the latching mechanism retracts and the door can be opened. But it was kind of rough on the fingers trying to turn that rod, so someone put a knob or a lever on the end.

The next question was how do we keep the knob on the spindle? Each lock factory had their favorite methods. The simplest was a square hole knob slipping over a square spindle, held in place with a setscrew.

A more complex method was a knob with a setscrew that when driven into the spindle, caused it to expand and thereby locking the knob in place. Later, as manufacturing methods progressed, the factories learned how to thread the square spindle rod. This allowed the knobs to also be threaded internally and screwed onto the spindle, secured in place with one or two setscrews.

So now we have a lock with a square hub, a square spindle that may or may not be threaded and a knob or lever that may or may not be threaded inside. Not that easy, you probably thought you were finished.

The lock manufacturers then learned that if they used a square rod that is 9/32” square (.281”), they could put a 3/8” thread on the four corners. It was easy to put a 3/8” thread inside the doorknobs, so this sounded like a good idea. Well, it seems that Yale Lock decided to use 3/8” -20 threads per inch for their spindles. Sargent Lock decided to use 3/8”-16 threads per inch. Lockwood went ahead and made their spindles 3/8”- 18 threads per inch. Other lock manufacturers picked and choose one of these various threads and of course none of these are inter-changeable.

To make matters worse, some lock makers thought that a 9/32” square spindle was not strong enough so let’s use a 5/16”, or 3/8” or even 1/2” square spindle. Of course when you thread these larger spindles you now have a larger thread size. If you put thread on the corners of a 5/16” square you get 7/16” thread and on a 3/8” square spindle you’ll end up with 1/2” thread.

To make life more miserable, Yale Lock decided that we were not capable of measuring a 9/32” spindle with a ruler. After all 9/32” is .281” which is almost .312”, which is 5/16” and how many of those little lines can you really count on a ruler (Remember that this was a long time ago). So when you looked in an old Yale Lock catalog, the 9/32” square spindles are actually called 5/16” square.

Mortise locks progressed and it was thought that it would be a great idea if the exterior knob could be locked and the interior knob would still operate. This was the birth of the swivel spindle.

Some mortise lock makers used two different sized hubs for the knob spindle. This prevented the spindle from being pushed through; it made the spindle installation self-centering. Typically one hub was 9/32” square and one was 5/16” square. But not always! One side might be 9/32” or 5/16” square and the other was 3/8” square. But the threaded portion of the spindle may still maintain the 9/32” square even though the center of the spindle is 5/16” or 3/8” square.

Along the way someone decided it would be nice if you could have a doorknob only on one side of the door. Typically the other side might have a sectional handle set. To accomplish that you would need a two-piece sectional spindle.

There are as many spindle variations, as there are ideas. In order to identify the correct spindle, consider the following.

1. There are three basic styles of spindles:

A. Straight spindles—primarily used for passage, non locking entries.

B. Swivel spindles—primarily used on mortise locks, provides a means of attaching two knobs or levers to the lock.

C. Sectional spindle—provides a means of attaching a knob or lever to one side of a door.

2. The size of the square rod, measured across the flats

If you don’t have the original spindle to compare to, it will be necessary to measure the lock hub diameter. An easy way to do this is by using a drill. Find the largest drill that will go into the hub. That’s probably the spindle size.

Remember, some locks use two different size hubs. You will need to measure both sides of the lock.

At this point it may get a little tricky. The center of a swivel spindle, the part that ends up in the lock hubs, may be fatter then the spindle ends. You need to establish the spindle size that goes into the knob or lever and also if the center is bigger.

A. The majority of spindles are 9/32” square

B. A smaller portion are 5/16” square, mostly for levers

C. A very small segment are 3/8” square

D. All the rest

3. Is the spindle threaded and, if so, what thread is it? The vast majority of threaded spindles are 9/32” square. This means the thread is 3/8” -?? Unknown pitch. To calculate the pitch, you either need a set of pitch gauges or if your eyes are good enough: a ruler and count the threads in one inch.

By now you should have an idea of the basic spindle you need. We have assumed that the spindle is threaded or not threaded. But there are also many other variations on how the knob is attached.

Tapped holes—Older style doorknobs did not have any thread in the base of the knob for the setscrew. The setscrew passed through the knob shank into a threaded hole in the spindle. These spindles may or may not be threaded and they could be straight or swivel.

Pin holes—Some knobs are pushed over the unthreaded square spindle and then a roll pin is driven into the knob shank and thru the spindle. The location of the pin hole is now important in placing the knob correctly. Some of our spindles have pin holes pre-drilled but they may or may not be in the correct location. In this case, the installer may have to drill his own hole. We also sell knob washers that go around the spindle and under the knob to take up any play.

Knob pinned to a swivel spindle:

Only one knob or lever can be pinned in this manner to the spindle. You need to pass the opposite end of the spindle through the lock body and attach the other knob/lever in some other manner. The traditional manner is to thread on the other knob and secure with setscrews. Several manufacturers have come up with some ingenious variations. Usually it involves driving the setscrew into some sort of depression or groove in the spindle.

Spindle with a stop pin or notch; the pin or notch actually stops the spindle from being inserted further into the lock hub when both hubs are the same size.

Removable center versus solid center: The method used to increase the size of the spindle center can vary. Some spindles were actually cast with a larger diameter in the center. This method was expensive and we instead use a square sleeve that is a press fit over the 9/32” spindle. The diameter of the sleeve is somewhat less than 3/8” so that it can pass through a 3/8” lock hub. In an emergency this sleeve can be knocked off if you have a means of holding the spindles and hammering the sleeve off. Important: This works well if you need a smaller spindle (9/32”) and didn’t bring one.

The other means of building up the center diameter of a spindle is with “Removable Centers.” This is an easy way to cover several options with one spindle. Use the spindle with two centers, use it with one center or use it with no centers. This type of center is not as substantial as a press on center but in a pinch it will work fine. However, be aware that its life cycle will be shorter.

We have talked a lot about swivel spindles. There is one common problem that pops up because it’s often forgotten. In order for the interior and exterior knobs to work independently, the swivel spindles halves must be able to swivel. To do this, before installing into the lock, lightly screw both halves together and then back off one turn. This is very important.

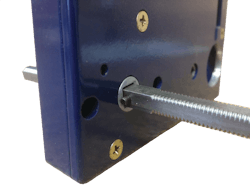

Photos 20-22 show a spindle being inserted into a mortise lock. Be sure that the center of the swivel spindle is in the center of the lock. Photo 23 shows a typical pair of lock hubs that has been removed from a lock to illustrate the spindle in its correct position

HOW LONG A SPINDLE?? The spindle needs to pass through the door thickness, through the thickness of whatever trim is in place and still have enough left over to attach a knob or lever. The easiest answer is to put back the same length you took out. If you don’t have the previous spindle, then you need to calculate a size. Try to measure the overall thickness of the door and trim together at the point the spindle passes through the lock.

Add to this size a sufficient length for spindle to attach your knob or lever. In photo 24, the door is 1-3/4” plus about ¾” of trim. The overall dimension is 2-1/2”. I want the spindle to thread at least 1” into each knob; therefore I want a spindle at least 4-1/2” long. Since my knobs on this lock are hollow, I don’t need to worry about the spindle being too long. Some knobs have a blind hole and levers in particular have this issue. In these cases it may be necessary to be more precise in the length of the spindle or you may have to cut a portion off.

I’ve often been asked what a locksmith should stock. First, know your customer base. Each town or city seems to develop around one or two major manufacturers over its life. But be careful, if a customer calls and tells you he or she has a Sargent mortise lock on their door. Don’t assume the spindle is threaded 3/8-16. It could have been previously replaced and it could be 3/8-20 threads per inch. As long as the knob and spindle are threaded the same, the lock really doesn’t care. Remember, it’s still only a square rod turning a square hub.

To help simplify matters, Progressive Hardware sells two spindle kits that will probably cover a majority of the mortise locks you will service. One kit is for 3/8-20 thread knobs. This is the majority of the country and covers Arrow, Corbin, Marks, National, Norwalk, Russwin and Yale. This is our Number 20.The other kit is for 3/8-16 and 3/8-18 thread knobs. This is aimed at Lock- Wood and Sargent knobs plus a few other companies. This is our kit Number 1618.

The #45-20-RTP Universal Spindle is always a good bet to keep around plus a pair of 20 thread knobs to go with it. Don’t get hung up on the idea that you have to put 3/8-18 thread knobs on a Lockwood mortise lock. The lock doesn’t care you only need something to turn the square hub. If the knobs fit the trim and the spindle works the lock, you’re done!

We have also developed a numbering system that should help you identify and purchase our spindles. In general:

The first 2 digits indicate if the spindle is Straight (44), swivel (45) or sectional (46).

The next 2 digits indicate the number of threads per inch, 16, 18 or 20.

The last digits indicate some sort of special characteristic.

Therefore a #45-20-P, is a swivel spindle (45), threaded 20 threads per inch (20), with a pin stop (P). A #44-18-5 is a straight spindle (44), 18 threads per inch (18), 5” long (5).

As a reference, Progressive Hardware has an available Spindle Chart that shows pictures of the majority of the spindles that we make.

For more information, contact Progressive Hardware at Telephone 631-757-8866, Fax 631-757-8870, e-mail [email protected] and online at www.progressive-hardware.com.