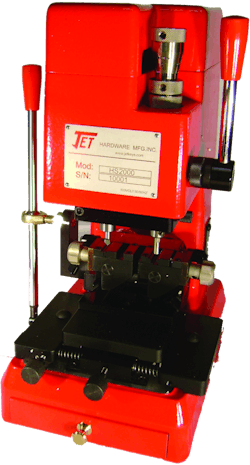

Just about every car manufacturer is introducing vehicles equipped with side mill lock mechanisms. To this end, Jet Hardware has introduced the model HS2000 “high security” key machine for duplicating side mill and dimple style keys. The HS2000 has the control lever on the left side and the depth lever on the right side.

Two tracer pins and four cutters are included with the HS2000 key machine. The tracer pins and cutters are manufactured of High Speed Steel (HSS), which is designed to withstand higher temperatures without loosing its hardness. The 2.5mm flat end tracer pin is used in conjunction with the 2.5mm cutter for most two- and four-track internal and external automotive keys.

The 2.5mm x 88 degree angled tip tracer pin is used with the three angled cutters: the 3mm diameter x 90-degree cutter, the 95-degree x 100-degree double ended cutter and the 90-degree by 105-degree double-ended cutter. Double-ended cutters are designed for duplicating dimple keys. Note: Consult the dimple key manufacturers’ specifications before duplicating any keys.

A patented feature of the HS2000 key duplicating machine is the spring loaded tracer pin. This spring permits the tracer pin to remain in the proper position when duplicating a dimple key by locating the dimple cut before making the cut into the blade. Note: The tracer pin can be locked at any depth position when required by tightening the Tracer Spring Set Knob for duplicating side mill keys.

The HS2000 jaws have a number of special features that provide ease of operation and the ability to duplicate non-standard keys. The Cross Plate Lock eliminates sideward movement in order to more easily duplicate dimple keys having aligned cuts. When the cross plate lock knob is tightened, only forward and backward movement is possible when duplicating keys. The Cross Plate Intelligent Control Knob locks the cutter and provides spring tension in order to keep the tracer against the edge of the pattern key’s cut area when duplicating side mill keys.

The patented synchronized tilting vise allows the jaws to tilt at up to a 45-degree angle in either direction. The pitch angle indicator is graduated into five -degree increments. Tilting is required to duplicate high security keys such as the Sargent Keso.

Cutting side mill keys is somewhat of an art form combined with practical applications. Unlike a cylindrical key, the side mill keys are placed within the jaws, making it very easy to accidentally cut the jaw.

The distance from the top of the jaw to the key ledge for the Jet HS2000 key machine is approximately .070”. Before cutting, determine the thickness of the key blank blade. When cutting around the edge of a thin key, use a clamp to avoid cutting into the vise jaw.

To better secure different shape key blades, the HS2000 comes with three sets of key clamps. These steel clamps have two setscrews, one on each side of the key blade slot to secure the key blank and the pattern key. This type of clamp secures the key by the upper portion of the shank, keeping the blade area available for the cutting. In addition to securing hard-to-clamp key blades, using the clamps avoid the possibility of damaging the vise jaw when cutting a key.

Each set of clamps is designed for specific applications. The 1070 clamp is designed to secure Mul-T-Lok type keys. This clamp is 1.45” long and has a .350” wide groove for blade. The clamp body is .275” tall. The inside groove portion of the clamp is .220”, having a .055” tray height for the key blade.

The 1071 clamp designed to secure the four-track (wide) Mercedes Benz (i.e. S7BW-PH) style and similar four-track keys. This clamp is 1.45” long and has a .300” wide groove for blade. The clamp body is .275” tall. The inside groove portion of the clamp is .220”, having a .055” tray height for the key blade.

The 1072 clamp designed to secure the two-track (narrow) Mercedes Benz (i.e. S34YS-PH) style and similar two track keys. This clamp is 1.95” long; .220” wide groove for blade. The clamp has two tip stops with slots at 1.53” & 1.65”. The clamp body is .275” tall. The inside groove portion of the clamp is .220”, having a .055” tray height for the key blade.

Note: The three sets of clamps are available separately. They can be used on just about every “High Security” key machine to hold more cumbersome keys.

The key has to be held in the vise jaws in order to be cut. The key blade must be higher than the top of the jaws in order to make the cuts without cutting into the jaws.

The model HS2000 side mill key machine is designed as a duplicating machine, but with space and depth keys can be used to originate “high security” keys.

When viewed from above the machine, the cutter rotates in a clockwise direction. Important: When duplicating or originating a side mill key, always perform the cutting procedure in a counterclockwise direction. If the cutter is moved in the wrong direction (clockwise), the cutter will bounce against the key blade and will not cut properly.

Note: Check cutter wear to be certain the cutter is sharp. If a burr begins to form, it is time to replace the cutter. It is worthwhile to replace the cutter at regular intervals.

For more information, contact your local locksmith distributor or Jet Hardware Manufacturing Corp., 800 Hinsdale Street, Brooklyn, NY 11207 Web Site: www.jetkeys.com.

To read additional Locksmith Ledger articles on Jet keys and key machines, visit http://tinyurl.com/jet0811.