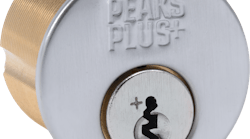

Scorpion Locks first appeared on the security scene less than two years ago with their CX-5 security lock cylinder. In addition to normal pin tumbler locking, Scorpion cylinders included a secondary sidebar locking system. They advertise quality, key control and pick resistance. Scorpion literature also states, "Scorpion keyway is of proprietary design and the distribution of key blanks is strictly controlled, with over 60 different sidebar combinations available per keyway." Scorpion key blanks are furnished with sidewinder cuts precut to one of the 60 sidebar combinations. Locksmiths can readily duplicate or originate tumbler cuts on standard key cutting equipment by gauging from the tip stop of the key blank.

Finger pins controlling the sidebar are not spring-actuated. The elimination of springs simplifies the locking system and removes one source of possible future malfunction. A wavy side milling on the Scorpion key blanks interacts with the finger pins. This wavy groove scrambles the finger pins as the key is removed from the cylinder. False cuts on the finger pins are designed to help deter attempts to pick the lock open.

Original Scorpion products featured replacement cylinders for mortise, rim and key-in-knob locks, plus a complete tubular deadbolt lockset. The latest introduction from Scorpion is a small format, interchangeable core cylinder. Some other high security lock companies with IC core products have had to furnish lock housings with special hole patterns to accommodate the amount of parts which had to be fit inside.

Scorpion says that their IC core lock cylinder is unique because it includes both pin tumblers and the sidebar feature for added security while maintaining the small format (SFIC) size. Since Scorpion cylinders can be retrofit into existing IC core housings, locksmiths now have a Scorpion locking system which can provide key control and pick resistance without requiring customers to invest additional amounts in new cylinder housings.

One easily overcome problem does arise when installing Scorpion IC core cylinders in existing housings. Normal IC core housings have two internal rods which are fastened to the cylinder tailpiece. The rods fit into corresponding holes in the IC core cylinder. Scorpion cylinders use a portion of one side of the lock plug for their locking sidebar, so one of the rods conflicts with the sidebar. The solution is to shorten one of the connecting rods. A special rod cutting tool is available from Scorpion. A simple twist of the wrist is all that is needed to shear off part of one connecting rod before initial installation of a Scorpion IC core cylinder into existing SFIC housings.

Scorpion CX-5 IC core pinning is accomplished in the same manner as pinning any other popular SFIC type lock. Pin sizes plus depths and spaces are also identical to popular SFIC lock cylinders. Tip stop spacing starts at .088 with .150 spacing from cut to cut. A CX-5 SFIC pin kit is available, but your current IC core pinning kit may be used to develop an A2 or A4 system for Scorpion IC core cylinders. Current Scorpion cylinders use individual set screws to cap each pin chamber. An optional pressed cap system will also be available shortly which should help speed the combinating proces.

Lock cylinders are available in six-pin or seven-pin configurations. It is possible to combinate cylinders so seven-pin keys can operate both six- and seven-pin locks. In this situation, six-pin sidebar combinations will be different than 7 seven-pin sidebar combinations. Scorpion publishes a CX-5 SFIC Service Manual which explains the combination requirements.

Scorpion CX-5 lock cylinders are designed to be serviced with most tools made for standard IC core cylinders. Companies such as A1, Pro-Lok and LAB are excellent sources for pins, loading tools, key punch machines and capping tools.

For more information on these products contact your local distributor or.

- Scorpion Locks, 888-636-3460

www.scorpionlocks.com - Pro-Lok, 714-633-0681

www.pro-lok.com - LAB, 800-234-8242

www.labpins.com - A-1 Mfg., 804-359-9003

www.demandA1.com