Locksmiths use a variety of tools and equipment on a daily basis. Some of this equipment is generic in nature such as drills, bits, screwdrivers, chisels and hammers. Other pieces are specific to our trade. These items include follow tools, picks, shims and lockout tools.

One piece of equipment is considered to be a 'must have' for any locksmith or security professional… the key machine. Whether your primary business is providing duplicate house keys for customers, generating large master key systems, servicing vending machine customers or specializing in automotive work, you need an accurate key machine. In fact, you probably need several key machines.

Locksmiths who have been in the business for decades will admit that it used to be possible to get by with one dependable duplicator and not much else. A manual key machine could duplicate keys and usually originate keys using space and depth key sets as the pattern keys.

To cut a full variety of today's keys, locksmiths need a mix of duplicators, code cutters, punches, tubular cutters and milling machines. There are major differences in these types of machines and their intended application will dictate their usefulness to your specific locksmith business.

KEY MACHINE TYPES

Key machines operate in three dimensions referred to as X, Y and Z-axis. X-axis is the left-to-right motion. Y-axis is moving in and out, while the Z-axis is up and down.

DUPLICATORS

Duplicators are the most common type of key machine. Manual duplicators allow you to control all functions of copying a cylindrical key. After clamping the original and key blank in the jaws, you apply the Y force against the cutter and the X motion. Different people will use different amounts of Y force, resulting in inconsistent key duplication. A large person usually exerts more pressure (Y force) than a small person.

For partially this reason, the semi-automatic machines have become the standard of the industry. These key duplicators allow you to clamp the keys and release the carriage toward the cutter. After that, a spring keeps a consistent Y force pressure against the cutter. You still control the X movement. Most of us will run through this left-to-right process twice out of habit. This assures us that a thick key with deep cuts is fully duplicated or as the cutter begins to wear, the key will be duplicated to the proper depths.

Fully automatic duplicator machines used to be found mainly in hardware stores either being leased or provided for little or no charge as long as a specific number of keys were cut every month. Many lock shops have them, and they have their place in your lineup. These machines have a fully controlled X motion and Y force. After clamping, a lever or button is pushed, allowing the machine to begin copying. A spring-fed carriage applies the blank against the cutter and a screw or shaft begins the X movement. These machines are usually rather slow and some run through two cycles to be sure the key is fully cut to depth. Some thick keys may need the process repeated.

Duplicators usually use a fixed cutter wheel depending on the application. A milling cutter for duplication of standard keys will be different than one intended to cut slots in flat steel or corrugated keys used for safe deposit boxes or warded padlocks.

Semi-automatic duplicators have the feature of being quick and the advantage of consistency regardless of who is using them. The benefit is that your customer gets a dependable duplicate key time after time.

CODE MACHINES

Code machines may be motor-driven or hand-powered. Computerized code machines have simplified the entire process of generating a first key. Code machines will cut a key to a specific set of cuts, usually provided by an external or internal code source or master key system chart. Code machines can use interchangeable cutter wheels with different profiles or angles, or may use a single cutter that controls cut width and shape by computer.

An 'extra' key can be made from a code machine if you know the cuts of the original. Rather than a duplicate key, this actually becomes an original key by code. Code machines have the feature of being versatile and the advantage of repeatable accuracy. The benefit is that you can generate a key to factory specifications every time.

NOTE: A code cut key is usually cut to the original equipment manufacturer's specifications. A duplicated key is cut to the depths of the pattern key.

PUNCH MACHINES

While in a somewhat separate category, punch machines are non-motorized code cutters. These bench top machines are powered by pressing down on a handle. This Z-motion forces a punch through the key blade at a depth controlled by a dial or slide. Code clippers are also hand powered by squeezing two handles similar to a pair of pliers. Punch machines use a fixed punch profile to cut keys. Punches can be dedicated to cut one brand of key or may be flexible, allowing you to interchange brand-specific components.

Punches are lightweight and very portable. The benefit is that you can carry it anywhere and create a code key in seconds without electricity.

TUBULAR MACHINES

Tubular machines are made specifically for tubular keys and can fall into the duplicating or code cutting category. Tubular keys come in different diameters and pin positions. Standard tubular keys are .137" in diameter and utilize seven pins in a circular format. The pins are centered or offset from the 12 o'clock position of the tab. Offset left and offset right are still considered standard. Standard tubular duplicators should duplicate left, center and right keys. Other tubular machines may be required to handle other key diameters. Tubular code cutters can be motorized or hand cranked.

HIGH-SECURITY MILLING MACHINES

Milling machines are available as duplicators and as key originators. Duplicators will usually have a controllable carriage. This can be set to a fixed Z depth position while allowing a free-floating X and Y-axis. Center milled or side milled keys are duplicated by controlling the carriage movement with the joystick. Using the machine similar to a drill press duplicates dimple keys.

Key originating milling machine are usually electronic and quite expensive. These machines are designed for the higher security, mainly automotive market. Several of the key originating milling machines have many of the key codes already programmed into the on-board computer.

Milling machines use a variety of different cutter bits depending on the key being cut.

MANUFACTURERS

Following is an overview of key machine manufacturers in alphabetical order and the types of machines they produce. Not every different model from each manufacturer is listed. At the end of each listing is the contact information for that manufacturer:

A1 SECURITY MANUFACTURING COMPANY

A1 Security Manufacturing offers punch and tubular key machines in addition to other related locksmith tools and equipment. The Mean Green Machine is designed to cut Best/Falcon type interchangeable core keys for the A2/A3/A4 BEST systems and features available interchangeable vises for cutting Medeco Keymark and Arrow Flexcore. (Pictured on p.10) The side-mounted depth knob and automatic key advance speed up the cutting process without missing cuts.

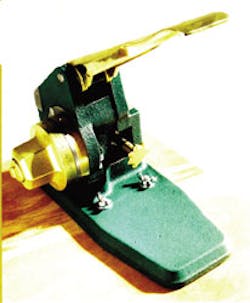

The Herty Gerty is a hand-operated code cutter for standard #137 tubular blanks. It will also cut offset left & right keys and will cut pin within a pin when used with the accessory cutter. The popular Model 3T PAK-A-PUNCH uses an interchangeable punch and die to punch all angles of cuts. (Photo 2) It can be used for foreign and domestic automotive, Kwikset, Schlage, Master and I/Core keys. A variety of packaged sets and accessories are available.

For more information on A1 Security Manufacturing key machines and tools, call (877) 725-2121 or visit www.demanda1.com.

BARNES DISTRIBUTION

Barnes Distribution, formerly Curtis Industries, offers six key cutting machines: the BD Laser™, PC+®, 3100, 2200, 1100 Key Duplicators, and the Curtis No. 15 Code Cutter. The BD Laser (pictured on p.11) is a fully automatic, computerized code cutter and duplicator for high security keys. This password-protected, microprocessor controlled key machine originates high security keys by code, decodes and originates keys to factory specifications, plus duplicates keys with minimal instruction.

The PC+ is a computerized code cutter/duplicator that uses make/model/year to identify the vehicle. The 3100 Key Duplicator is an automatic key machine that can also be used manually. The 2200 Key Duplicator is a semi-automatic key machine that is handle-operated. The 1100 Key Duplicator is a manual. The Curtis No. 15 Code Cutter is a hand-held key origination machine for vehicles, motorcycles, and recreational vehicles. The No. 15 machine has interchangeable cams and carriages in order to originate keys for most automotive pin and wafer tumbler locks. In addition, Barnes Distribution offers a complete line of vehicle code books.

For more information on Barnes Distribution key machines, call 800-555-KEYS or visit www.BarnesDistribution.com.

BIANCHI USA INC.

The Bianchi family tradition in security products began in northern Italy in 1770. In more recent years, the family expanded into key duplication and transponder servicing tools. Their range of products include the Bianchi 101 manual, Bianchi 102 and 104 semi-automatic and two versions of the Bianchi 303 and 304 high security duplicators. The Bianchi 303, 104 and 101 are shown left-to-right. (Photo 5) Weights of these cast iron machines range from 37 to 57 pounds, resulting in dependability under heavy use. "L" style jaw handles and reversible jaws are specifically designed to handle the longer, larger headed keys. The high-security machines feature three-dimensional calibration for greater cut accuracy. The 303 can be upgrade to a 304 by purchasing the 304 jaw assembly which includes tilting jaws and removable faceplates.

For more information on Bianchi key machines and tools, call (800) 891-2118 or visit www.bianchi1770usa.com.

FRAMON

Frank Agius began locksmithing in 1959. After becoming frustrated with key making devices of the time, he designed a code machine for his own use. Framon now offers nine different key machine models including duplicators, code machines, and machines for cutting tubular, flat steel and high security keys. The Framon #2 is a manual code machine designed to handle standard cylinder keys, foreign and domestic automotive keys, as well as keys for motorcycles and padlocks. It can also handle letterbox, safety deposit, I-Core and high security commercial keys.

The FRA-2001 is a computer-driven code machine. The machine has no keypad, but uses a serial cable connected to your computer. Two servomotors and sealed ball bearings provide a smooth operation on both axes, cutting a six-pin key in about 15 seconds. A reversible vise, shoulder and tip stops are included.

The Sidewinder is a high security automotive duplicator. (Photo 7) It's designed to quickly and accurately cut Mercedes 2 and 4 Track, BMW, Lexus, Infiniti, Volvo, Volkswagen, Audi and Saab keys. Four cutters come standard.

For more information on Framon key machines and tools, call (989) 354-5623 or visit www.framon.com.

HPC

HPC offers at least 15 different key machines, including five types of code cutters, six types of duplicators and three types of tubular machines. Code cutters include the famous HPC1200CMB Blitz (Photo 8), the computerized Blue Shark stand-alone hand-activated robotic key machine, the 1200MAXAA Codemax computerized code machine and the 1200PCH Punch Machine. In addition, the 1200CMSB is the Switch Blitz combining a code machine and duplicator.

Duplicators include the 6666HQT fully automatic and 3344HQT semi-automatic machines. (Photo 9) The DM-500 Drill Mill utilizes a portable drill to provide power to the lightweight bench-mounted key duplicator. Tubular keys can be cut on the HPC/Scotsman 747XU Duplicode (Photo 10), 747E Econo Duplicut or on the TKM90 Pocket Cut-Up which requires no electricity.

For more information on HPC key machines and tools, call (847) 671-6280 or visit www.hpcworld.com.

JET HARDWARE

Jet Hardware, an aftermarket key blank manufacturer, has been marketing key machines for more than 20 years. Jet has six different duplicators. The 7010 is a basic manual key duplicator, and the 7020 is a basic semi-automatic key duplicator.

The Jet 7060 Ultimate Extra Heavy Duty Semi-Automatic key duplicating machine is designed for commercial/institutional applications where hundreds of keys are duplicated a day. The 7080 Jet Deluxe key duplicator is a combination of a semi-automatic and automatic. The 7090 is a deluxe semi-automatic key duplicator. The 8000 fully automatic key duplicator can be operated manually for special applications. All of these key duplicators are furnished with M2 steel high speed cutters for long accurate key duplicating life.

For more information on Jet Hardware key machines, visit www.jetkeys.com.

INTRALOCK TOOLS LIMITED

ITL offers three computerized code machines. The ITL9000 has more than 800 built-in manufacturer depths and spaces and works with most popular master key systems. New codes can also be added. It uses a serial port to communicate with user systems. Sealed and pre-lubricated bearings offer repeatable accuracy of 1/1000th of an inch.

An industrial version, the ITL9700 Code Machine features a carbide cutter, and four cut modes. A new Medeco Autoswing head is optional.

The ITL950C is a mobile code machine with over 500 codes built in, including most Domestic, Japanese and Korean codes. It will operate on 12VDC or 120VAC power.

For more information on ITL key machines and tools, call (888) 264-6627 or www.intralocktools.com.

KABA ILCO

Kaba Ilco Corporation offers more than 36 key machines, with choices ranging from the simple to the extreme. The selection of machines was greatly enhanced with the addition of the Silca line.

The popular Bravo III (Photo 15) is a semi-automatic duplicator with four-way reversible jaws and wide spacing between the vise jaws to accommodate long and large headed keys. It has a micrometer-type cutter guide adjustment system and a carriage release button that will only activate when the key gauges are in the down position.

The Nova 2000 (pictures on p. 16) is a basic duplicator for both center-milled and side-milled high security auto keys. It will also duplicate dimple-type keys. Accessory adapters enable the machine to duplicate other high security key types.

The Quattrocode is a computer operated key machine with many automated functions. It can decode a worn sample key, compare it to an on-board database and automatically adjust to factory original lock specifications. Included popular high security code series are stored on-board for cutting keys by code.

For more information on Ilco key machines and tools, call (252) 446-3321 or visit www.kaba-ilco.com.

PRO-LOK

PRO-LOK rescued an old popular key machine from certain death. Sold under various names including Codemac 101, Keymak, Automatic Security Machine, City Punch, Armbruster and a few others, the PRO-LOK BP201 is better than the original. In about 1994, Pro-Lok bought the rights to and began reverse-engineering a machine that would become the Blue Punch. (Photo 17) The BP201 is sold in 12 versions. Manufacturers supported include Arrow Flexcore, Corbin C70, Dexter/Master, Falcon/Weiser, I/C A2, I/C A3, I/C A4, Kwikset, Schlage (Obverse/Primus/Everest C/ Everest Primus), Schlage Everest B, Schlage Reverse and Weslock. The Blue Punch is a dedicated machine designed to cut factory original keys by code. After clamping, the depth slide provides accurate depths and the carriage advances automatically as the handle is pushed down. These portable, compact hand-powered machines can be operated in a shop, service vehicle or right at the customer's door.

For more information on PRO-LOK key machines and tools, contact them at (714) 633-0681 or visit www.pro-lok.com.

RYTAN

Rytan Incorporated offers four duplicators and two punch code machines along with a variety of specialized locksmith tools and equipment. The original RY100 universal semi-automatic duplicator is available, and the new RY2000 has been upgraded with the addition of new four-way vises, a new carriage, standard wire brush kit and a new cutter.

The RY256 ramm cuts standard and Medeco keys with its tilting head. The RY45 manual duplicator, like all Rytan products, is made in the United States.

The new RY2000 Extreme Punch comes in two versions. The RY2000 will accept up to nine different Quick Kits, one at a time. Cut Schlage, Schlage Reverse, BEST I/C, Dexter, Kwikset, Weslock, Weiser, Arrow and Corbin.

The RY2000 Dual Machine is allows you to set up the machine to cut two different manufacturers by simply changing one space bar. A variety of manufacturer combinations are available.

For more information on Rytan key machines and tools, call (800) 447-9826 or visit www.rytan.com.

DECIDING FACTORS

Purchasing any key machine requires some research on your part. In addition to cost, determine the value the machine will bring to your business. By offering additional services to your customers, you can build more business. Determine what attachments and options are available for a given machine. The addition of a brush or work light can increase your productivity.

Consider the warranty or guarantee along with the manufacturer's reputation. Ask your colleagues in the industry. See what machines your friends are using and how they like them. Recommendations -- both good and bad -- can have a strong impact on how you spend your hard earned dollars.

What are the features, advantages and benefits of each machine? A feature is 'what it is,' an advantage is 'what it does' and a benefit is 'how it helps you.' See if different cutter blades are available and how much replacement cutters will cost. Examine the accuracy of the machine and read the factory specifications before you buy. Are the jaws two-way, four-way or fixed? Four position jaws allow much more flexibility in duplicating customer keys. They can also allow for broken, worn or odd key duplication.

What is the application of this machine? Will it be used in a shop, in a truck or both? Buy the right machine to do the right job.

INVESTMENT OPTIONS

A key machine is an investment. It is a tool that will allow you to make money. Check with your distributor to find out what options are available. Some machines come with a group of free key blanks. Free key blanks are almost as good as cash. Some distributors may be willing to work with you by offering extended dating. There are companies that will allow you to lease or finance a key machine.

Do your homework before you buy your next key machine. The time and effort you spend is worth it considering that key machines are a long-term investment, usually offering a substantial return on that investment.