The Locks With a Magnetic Personality: Are Mag Locks Really the Easy Way Out?

The family of electrical locking devices available to the door control designer is ever-growing. It’s imperative that the system designer/installer stay educated informed and up to date on all locking technology. This enables the system designer more options and enables that the proper locking device be specified for each application. Well, at least that’s the way it should be.

However, in the real world, lock specification is instead directed by other priorities such as:

– The architect liked it: (“I Love the Luster!”)

– Cost (“What’s the cheapest thing you got?”)

– Ease of installation (“Stand back Dave, I’ll make it fit”)

– What already in stock (“If I don’t get that thing off the truck soon, it’ll be too road-burned to sell”)

– What was used on the last job seemed to work OK (“They haven’t called so it must be working”).

We are all creatures of habit to some extent, so why not develop some good ones?

Here’s a list of locking devices used for electronic door control.

– Electric Strikes

– Electric Bolts

– Electrically actuated cylindrical locks

– Electrically actuated mortise locks

– Electrical latch retraction devices

– Electrically actuated trim

– Motorized electric locking devices

– Shear Locks

– Standalone Access Controls

– Standalone Egress Controls

– Electromagnetic Locks

On my list, electromagnetic locks are last but definitely not least, but it’s hard to determine where the electromagnetic locks rank of importance in the evolution of access control. It can be said that they’re perfect for many applications; and there has never been a better assortment of them from which the system designer can select.

The characteristics that set electromagnetic locks apart from all other electric locks are:

1. They usually have no moving parts.

2. There is no integral means of unlocking them.

3. They are fail-safe and require power in order to lock and power to be removed for them to unlock.

THE EASY WAY OUT?

Having no moving parts, electromagnetic locks are sometimes regarded as an “idiot-proof locking solution” for unskilled installers or for use on problem doors. Consequently, many electromagnetic locks are installed unsafely.

Although it is true that electromagnetic locks are relatively simple to mount on a door and a door frame (essentially requiring less than ten holes to be drilled), those other two inherent characteristics (they have no integral means of unlocking them and they are fail-safe and require power in order to lock and power to be removed for them to unlock) make the proper application of electromagnetic locking systems something to be attempted by a qualified locksmith.

Installation of electromagnetic locking systems requires proper system design and skill. It should be treated as serious business because if not done properly, electromagnetic locks can be hazardous to building occupants (even trapping occupants in a burning building).

Electromagnetic locks have NEITHER levers nor buttons on them to unlock them, so thought and planning must be put into where they are used and the design of the system that controls them so that they are safe for the building occupants.

THINK LIKE THE LAHJ

Misapplication has earned electromagnetic locks a bad reputation among building inspectors and fire marshals.

Be sure that electromagnetic locks are permitted in your jurisdiction, and even better, document your installation, listing the components you plan to use, how it will be wired and the location of the door on which it is to be installed, and arrange a meeting with your LAHJ (local authority having jurisdiction) to go over it with him. Although electromagnetic locking systems are widely deployed, your LAHJ will have the final word.

Manufacturers of electromagnetic locks and accessories design their products to meet many standards of manufacturing quality and code compliance, and the reputable manufacturers have help available on-line, via help desks or through their national network of skilled reps.

Also, it may be a benefit to you and reassuring to your LAHJ to know that the electromagnetic lock you are using is BHMA/ANSI a156.23 certified. For certification information, visit http://www.buildershardware.com/2010.html.

MAG LOCK SYSTEM COMPONENTS

Power supply: The output of power supplies for electromagnetic locks are typically either 12 or 24 volts. The power supply may be as simple as a plug-in type or as complex as a hard-wired locked cover multiple regulated output unit. Many power supplies are available with back up batteries to provide power to electromagnetic lock in the event of a power failure, as well as terminals for connection to the FACP (Fire Alarm Control Panel) If you are not licensed for electrical work, you may want to exclude the actual final hookup of your power supply to line voltage from your proposal, and hire an electrician to do it.

Auxiliary controls: This broad family of products includes items such as REX (Request-To-Exit) pushbuttons, motion sensors, key switches, keypads and access control systems. Virtually every installation will require auxiliary controls.

Emergency release: This is a critical area, and group of products which if properly selected, connected and installed, will make the electromagnetic locking system not only secure, but safe as well.

The system design goal is of course to be both safe and secure. In an emergency, such as a fire, the door cannot impede egress.

Emergency release measures include not only exit bars and pushbuttons mounted on the door which unlock the electromagnetic lock, but also specialized devices such as pull stations and connections between the electromagnetic locking system and the building fire alarm and/or sprinkler system.

Electromagnetic locking systems must be designed with deliberate measures in place to cut power in order to guarantee safe egress. Designing an electromagnetic locking system around the assumption that if there is a fire or other type of emergency, the building power will shut off, and therefore the electromagnetic locks will unlock, is a dangerous assumption to make on behalf of innocent unknowing building occupants whose lives may be placed in jeopardy as a consequence.

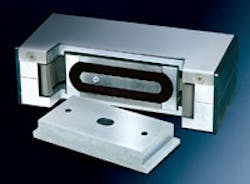

Electromagnetic lock: Electromagnetic locks are now available in a wide range of sizes; holding powers; finishes; mounting options; functions; and integrated into self-contained systems. The electromagnetic lock assembly is comprised of two major parts-- the coil, which mounts on the stationary door frame and which receives power and the armature, which typically is mounted on the door itself by means of a special bolt assembly which allows for the armature to pivot and thereby align securely with the armature.

Size: Generally the size of an electromagnetic lock is function of the number of doors it is designed to secure. For most security applications, what is referred to as a 1200-1500 lb. magnet is considered standard for a single door. For access/door control applications, smaller magnets are available. Pairs of doors usually are set up with dual electromagnetic locks which are mounted in a single housing. This arrangement allows for maximum holding force, individual control over each door leaf, and a simpler installation with a single housing to attach to the door frame. If individual door control is not a requirement, and if less holding force is allowable, then some electromagnetic locks are offered in a single size but with two half sized armatures.

Finishes: Electromagnetic locks are provided in all architectural finishes, and may also be plated and painted to suite the installation requirements. Outdoor and ‘high security’ applications may require that the electromagnetic lock or armature be rust resistant or special provisions, such as pipe fitting be provided to protect wiring from tampering.

Mounting: The standard electromagnetic lock installation is on interior out swinging doors where the electromagnetic lock is placed on the top of the doorframe. This is a good place for them because they are less likely to obstruct the opening’s width or get bumped into by heads, arms, wheelchairs, etc.

But electromagnetic locks can be adapted for virtually any type of door. When a non-standard installation is planned for an electromagnetic lock, even more attention should be paid to the life-safety and security aspects of the installation. This is because even if an electromagnetic lock can be made to physically mount on an opening, the resulting installation may not offer the life safety or security characteristics required.

Sometimes a ‘non-standard’ installation can offer a substantial enhancement to the security and safety of an opening. One example is the vertical mounted electromagnetic lock. These installations deploy one or two electromagnetic locks vertically in the opening of an out swinging door resulting in a highly secure result. These arrangements overcome a known drawback of the top jamb installation, which will frequently result in warped doors, and reduced security due to flexing of the door which is being held shut from a single point at the top.

Electromagnetic locks can also be adapted for Herculite doors, sliding doors, overhead doors or gates.

Functions: Electromagnetic locks are available with many convenient functions built in. Some electromagnets allow field selection of operating voltage, can monitor door position, lock status, can time the unlock time, or can signal they are unlocked audibly or visually with integral enunciators or auxiliary contact outputs.

Integrated Systems: Many electromagnetic locks are actually complete systems. One popular configuration is the Delayed Egress system, which requires only power to operate. Electromagnetic locks are also offered with integral REX motion sensors, and even wireless receivers to permit remote unlocking. Besides simplifying the installation, integrated locks may be tested, approved, and listed as systems; which means the LAHJ will like them.

ADAMS RITE

The MS® Maglock by Adams Rite is a unique class of maglock that is perfect for virtually any application. Its compact size, 4,000 pound rating, light weight, low current draw and access control compatibility has made it the preferred choice of specifiers and installers across the nation. The MS® Maglock can be ordered with optional door position switch or tamper alert sensor. For maximum strength and convenience, it’s the only maglock you will ever need.

For information, call (800)-87ADAMS or visit www.adamsrite.com. Indicate 420 on eInquiryDOORKING

DoorKing offers a wide range of high quality magnetic locks and brackets to accommodate almost any door locking requirement. DoorKing also offers a 2000 Lb shear lock which provides both a magnetic and mechanical connection. Most locks are available in both surface and flush mount designs and can be ordered with options such as LED lock status indicators, signal relays and built-in timers.

For information, visit www.doorking.com. Indicate 421 on eInquiryDYNALOCK

The DynaLock Series 3000 Electromagnetic Lock features 1500 Lbs. holding force, installer-friendly FasTrak mounting and is field reversible for left or right hand wire entry. Modular on-board electronics include available door position and bond status sensors, relock timer and a bi-color LED indicator. Dual voltage 12/24 VAC/VDC input and the exclusive DynaLife lifetime warranty make the 3000 the ideal choice for commercial, industrial or institutional openings where maximum security and durability is required.

For information, call (877) 396-2562 or visit www.dynalock.com. Indicate 422 on eInquiryRCI

RCI’s 8310 MultiMags are hard-working multi-purpose electromagnetic locks that enhance building security and install quickly. Several standard features make these magnets the “workhorse” of the industry. The adjustable mounting bracket has been enhanced with keyhole mounting to support the magnet’s weight during initial installation, freeing the installer’s hands to affix the magnet mounting screws. The removable cavity cover offers quick, easy access to wiring.

For information, visit www.rutherfordcontrols.com. Indicate 423 on eInquiryROFU

The powerful MODEL 8011x002 electromagnetic lock by ROFU, which has a holding force of 1500 lbs., comes with an attractive, heavy-duty anodized extruded aluminum housing and a built-in Hall effect crystal which is affected by door position, voltage input and magnetic field strength. The lock comes fail safe and is available in either 12V or 24V. Mounting hardware is included with the unit and optional Z-Bracket is required for inswinging doors.

For information, visit www.ROFU.com or call 1-800-ALL-ROFU. Indicate 424 on eInquirySDC

SDC 1500 series EMLocks include a lifetime warranty and are available in 650lb, 1200lbs, and 1650lbs holding force. All EMLocks are adaptable to any application utilizing Top Jamb or Glass Door mounting kits. All options, door status and magnetic bond sensors may be added or replaced in the field without removing the lock from the frame. The epoxy-less design provides a superior appearance. The interlocking EZ mount assembly leaves hands free for wiring and securing of mounting screws. EMLocks are UL Listed and ANSI Grade 1 compliant.

For information, visit www.sdcsecurity.com. Indicate 425 on eInquirySECURITRON

The M38 and 68 Magnalocks from Securitron offer the next level of electromagnetic security. With 600 and 1,200 lbs. holding force respectively, these automatic dual voltage locks offer a fool-proof mounting bracket that makes installation faster, easier and more accurate. They also feature a built-in wire access chamber that allows for wiring at the lock. Both locks are available in with several additional options to suit any application including a door position switch, an LED status indicator, anti-tamper sensor and Senstat.

For information, visit www.securitron.com. Indicate 426 on eInquiry

Tim O'Leary

Tim O'Leary is a security consultant, trainer and technician who has also been writing articles on all areas of locksmithing & physical security for many years.