Does Your Business Hinge on Profit? An Overview of Butt Hinges

Hinges. Do you sell them? Do you service them? Do you replace them? Many locksmiths service the leading edge of the door from top to bottom. From kick plates to flush bolts and levers to deadbolts, the door gets full attention. You'll even install door closers. But why not examine the profit opportunities from the hinge side as well?

Hinges are jointed devices, where one leaf is attached to the jamb, allowing an attached part, such as a door to swing inward and/or outward. When you research hinges, here's just a sample of what you'll find: cabinet hinges, spring hinges, door hinges, gate hinges, invisible hinges, continuous hinges, furniture hinges, finial-tipped hinges, piano hinges, kitchen cabinet hinges, weld-on hinges, concealed hinges, satin nickel hinges, butt hinges, strap hinges, toy box hinges, window hinges, shutter hinges, glass door hinges, brass hinges, stainless steel hinges, pivot hinges, offset hung pivot sets, center hung pivot sets, specialty hinges and more.

From the standpoint of sales and service opportunity, I decided to concentrate on the most common type of hinge that a locksmith will encounter, the standard industrial butt hinge and some of its variations.

HINGE TYPES

Choices for industrial hinge types include butt hinges, half-mortised hinges, swing clear hinges, spring hinges, inside stop hinges, outside stop industrial hinges, and weld-on hinges. Other features of industrial hinges include unequal leaves, MIL-SPEC, and hinge direction. On non-standard doors and frames, proper operation of the door may require unequal leaves. Extra-thick doors, doors with a decorative veneer, specially designed frames and trim or wall conditions may require the use of special hinges with unequal leaves.

In some government applications, hinges will be specified as MIL-SPEC. As the name implies, all Military Specifications must be met to approve the hinge for usage on the application in question. Some of the numerous special requirements may be hinge leaf and pin length, 'loops and/or tangs' (knuckles) must be designed in a certain fashion, tolerances that need to be met and base material and finish specifications that are allowed and disallowed.

Hinge direction refers to hinges that are non-reversible and must be installed in the proper direction to work as designed.

Physical specifications to consider when searching for industrial hinges include base material, finish material, leaf thickness, leaf length, pin material, pin diameter, knuckle length, open width, hole type, and number of holes.

Butt hinges are composed of two leaves attached to abutting surfaces of a door and frame, joined by a pin. The pin is contained in the knuckle segment of each hinge leaf. Withdraw the pin and the leaves will separate, allowing the mounted door to be easily removed from the frame. The two leaves are each fitted with screw holes. For installation, both leaves of the hinge are usually fully mortised, one into the edge of the door and one into the edge of the frame. When the door is closed, the leaves meet (or butt together) with only the pin knuckles showing.

Half mortised industrial hinges are butt hinges where only one of the leaves is mortised into the door and the other leaf is attached to the surface of the frame. A half surface hinge is mortised into the frame and the other leaf is attached to the surface of the door.

Swing clear hinges are designed for use in hospitals, institutional or commercial buildings for barrier-free applications, wherever doors are required to meet barrier-free codes (ADA) or are required to swing completely clear of the door opening so that wide equipment can pass through without damaging the doors, frames or equipment. A swing clear hinge projects the door at least 90 degrees out from the opening.

Spring hinges allow doors to close automatically or be held in the open or closed position. Depending on the size and weight of the door, spring hinges may be required in more than one hinge position, or a stronger spring hinge may be required. If spring hinges are used with additional architectural hinges, they must be ball bearing, not plain bearing hinges. A ball bearing hinge has ball bearings that contact the knuckles from jamb and door leaves. Ball bearing hinges operate smoothly as only the bearings contact the knuckles of the leaves. A standard butt hinge has the metal of both leaves knuckles contacting each other. They rub against each other as the door is opened and closed.

In some applications the spring hinge is used in place of a hydraulic door closer. Although it's more economical it may not produce the desired results. Unlike a door closer there is no "sweep" or "latch" control. The only adjustment is how much pressure is exerted onto the door. The more pressure the faster the door swings closed.

Double acting hinges will allow the door to open in and out, allowing the door to be pushed open in either direction.. A double acting hinge is created by adding a third leaf and a second pin/knuckle assembly. The double acting hinge is capable of operating in two directions. When the door is opened in one direction, two leaves of the hinge remain flat against the frame side while the third hinge rotates with the door. When the door is opened in the opposite direction, one leaf of the hinge remains flat against the frame side while the second and third hinge rotate with the door. A good example is a restaurant kitchen/dining room door application where people will be entering and exiting on a repeated basis.

Inside stop hinges normally operate from the 0 degrees or closed position towards the open position, stopping at 90 degrees. Outside stop hinges normally operate from the 180 degrees or flat, open position, towards the closed position, stopping at 90 degrees. For special applications, some hinge manufacturers furnish special stop angles.

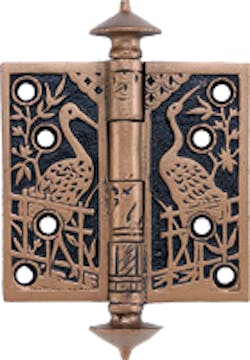

Decorative hinges in a variety of styles and shapes. They add style to the common hinge. Although not commonly used on today's commercial office buildings, some older buildings can have an exquisite examples of them. With all of the sources at our fingertips on the Internet, you may find just the style of decorative hinges your customer wants to go with that decorative hardware.

Weld-on hinges are just what the name implies, hinges that are designed to be attached by welding them into position instead of using screws.

HINGE MATERIALS

The quality of door hinges is determined by the way they are produced. Stamped hinges are low-cost, made of thinner material and considered residential grade. Extruded hinges could either be residential grade or higher-quality architectural grade hinges. Hand-cast bronze door hinges would always be considered architectural grade. Choices for construction materials for industrial hinges include aluminum, brass, bronze, steel, and stainless steel.

PINS AND TIPS

The pins of the hinge may be constructed from alternative materials of the main body and these include aluminum, brass, and stainless steel.

The caps or tips (finial) on a hinge can be plain or fancy. Some hinges are designed with the tip fixed in position while others have a separate, replaceable tip. Special sloped tips are designed for hinges used in hospitals. The declining slope prevents anyone from hooking or hanging anything on the tip of the hinge, reducing the possibility of injury or suicide.

FIRE RATED

Hinges used on a fire-rated door must also be fire-rated. You must use steel or stainless steel base material, ball bearing hinges. Brass and bronze hinges will melt under extreme heat causing the door to fall out of the frame.

HINGE SIZES

Hinges come in a variety of sizes to fit just about any door and frame setup you encounter. Most common applications will fall in between the 3-inch by 3-inch to the 6-inch by 6-inch sizes. The size of hinge used is usually determined by the application. If a door and frame were manufactured to use a specific size hinge, for example a 4.5" X 4.5" butt hinge. Then only that size hinge or a swing clear hinge would be the proper size to properly replace it without modifying the door or frame.

STANDARD OR BALL BEARING

Residential hinges are designed for the knuckles of the hinge to rotate against each other. In a residential setting, the usage is such that the wear of metal against metal will still allow a long life. When the wear becomes excessive, the door can begin to sag, become misaligned and will eventually bind. It is usually when the door no longer closes will the hinge be replaced with a new one.

When do you determine if a ball bearing hinge is better than a standard hinge. The weight of the door and how frequently the door is used will determine the type of bearing required. Plain bearing hinges are designed for low frequency use of a door of standard weight.

Concealed or ball bearing hinges are designed for use on standard weight doors in medium frequency service. The use of ball-bearing hinges is most common in commercial and industrial settings. The ball-bearing hinge is usually permanently lubricated and is designed for use on heavy exterior doors. Although it is more expensive, any interior or exterior door in a heavy use application can benefit from the use of ball-bearing hinges.

HANDING

Most hinges are non-handed and can be reversed. With a loose-pin hinge be sure it is installed with the pin inserted from the top of the hinge. If the pin is left upside-down, it may fall out during normal usage causing the door to come partially off the hinges. For some special application hinges they are specified as left-hand or right-hand and cannot be reversed.

HINGE SELECTION

The height, width, thickness and weight of the door will determine the correct type, size and style of hinge, and the number of hinges required to properly support the door. The accompanying chart is just one example of some of the basic information needed to help you decide the proper hinge for the job. For complete information on choosing the proper hinge for the job go to your favorite hinge manufacturers catalog or website.

HINGE TOOLS

When hinges are installed in a wood door they can be aligned and mortised by hand. This can works fine if you're only doing one door. For the more experienced professional a hinge alignment guide is available to do the job. Manufactured in fixed or adjustable versions, the hinge routing template allows you to attach it to the door edge and quickly rout out the mortise cavities for the hinges.

Available for various types of residential and commercial grade hinges are service tools are used to straighten bent or misaligned hinges. By attaching the tool to the hinge knuckles. Realignment is most often required for the top hinge since that is the point of greatest stress. Occasionally a middle hinge will need adjustment, rarely a bottom hinge.

With the Hinge Doctor, as the door is slightly opened, the tool binds and forces the hinge back into its original position. With the Hinge Tweaker, force is applied through the built-in handle. With either tool, small incremental adjustments are advised. Adjust slightly then recheck operation of the door. The convenience is that you can adjust hinges while they are still on the door and frame.

IMPORTANT: Before making any adjustments, make certain the screws securing the hinge to the door and frame a tight. If any are loose, tighten them. If the hinges are mounted onto a wood door and frame and the holes are enlarged, use a bamboo chopstick or wood dowel to fill the hole and then install the screw.

Keep in mind tweaking the hinge is a quick fix and may not solve the problem entirely. If a hinge is broken or severely bent, replacement is probably the best solution.

OUTSWINGING DOOR SECURITY

Many hinge pins can be removed by tapping them out. When a door is closed and locked, removing the hinge pins may compromise the security of an out-swinging door. With the pin out, the door can be pried open (sheared) on the hinge side and simply removed from its opening.

To prevent removing the hinge pin, some hinges have a Non-Removable Pin (NRP). This pin is either permanently fixed at the factory or may have a setscrew that is reachable only when the hinge is in the open position. The setscrew is tightened down against the hinge pin after installation so that the pin can't be removed when the door is closed.

Another way to add security to an out-swinging door is to add security pins to a standard hinge. These pins replace one screw in one hinge leaf and have an extended head that protrudes into the matching screw hole on the opposite leaf.

When the screw holes in the hinges are in a 'template' format the holes line up with each other when the hinge is closed. (Photo 13) When the screw holes are in a 'zigzag' format the holes are offset from each other when the hinge is closed. (Photo 14) With a zigzag hole pattern a corresponding hole must be drilled to accept the extended screw head. In either style, when the hinge is closed the extended screw head prevents the shearing of the two leaves to gain access.

ELECTRIFIED HINGE NOTE

In many commercial applications a fire rated door has been prepared for electrical locking hardware. Sometimes the locksmith does this; sometimes a 'labeled' factory prepares it. Many hinges used for passing power are not fire rated. If these power transfer hinges are rated "BP" (Burglary Protection) UL634 they are rated for connectors and switches as this rating does not contain any fire resistance requirements applicable to fire doors. You can find a listing of UL fire rated power transfer hinges in the UL Fire Resistance Directory.