When it comes to vehicle entry, the word “wedging” seems to mean different things to different people. To some, it’s just a part of the job, and to others, it’s something to be avoided at all costs. I suspect that those who avoid wedging have either broken a car window or fear that they will. Those who have too casual an attitude toward wedging will all too often have a sudden change of heart as they pay for that first broken window.

My career as a locksmith has spanned over 30 years, 20 of which were spent figuring out how to unlock brand new cars and teaching hands-on vehicle entry classes. During those years, I’ve probably wedged more car windows per year than most locksmiths will in their entire career. So far, I have managed to break just one car window, and I didn’t break that window with a wedge. (I did it using only two fingers while removing a prototype tool from the door of a brand new car at the dealership. That window cost me $213.20 in 1993.) I’m going to try to pass along a little of my experience in this article in the hopes of saving you from ever experiencing that sickening feeling that comes with watching a car window shatter in front of your eyes.

There are basically two types of wedging that goes along with vehicle entry: wedging open a gap at the base of the window so that you can insert a tool, and wedging the door itself so that you can insert a long reach tool such as the Jiffy-Jak. I’ll begin by discussing the typical kind of wedging that is required to insert a tool into the door.

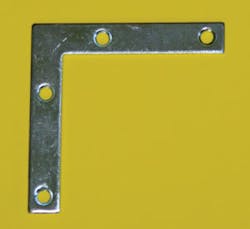

The first type of wedging that I ever saw wasn’t what you would truly call “wedging,” and it still gives me the willies just thinking about it. It was the use of a flat-steel “corner brace” (photo 1) inserted between the glass and the weather stripping, and then rotated to open the gap. This is a recipe for disaster in my opinion, and I strongly urge you to avoid this practice. The square edges of the steel brace, coupled with the large amount of leverage that you can get with this technique, make it just too easy to break or scratch a window.

The most common form of wedging uses a wedge-shaped object that is pushed, with varying degrees of force, down into the door between the glass and the weather stripping to open the gap.

There are many different types of wedges out there, and just as many opinions on how to use them. To my way of thinking, there are basically three different types of wedges: hard plastic wedges, soft plastic (rubber) wedges, and wooden wedges (photo 2). My preference is for the wooden wedges, because they will deform if they hit something in the door such as a window track or fasteners. A wooden wedge will also break or crack easier than most windows, and if anything is going to break, I would prefer that it be my wedge rather than the window glass.

I will occasionally use a hard plastic wedge, but I am much more observant when I do. The biggest advantage to using a hard plastic wedge is that they maintain a sharp edge much longer than wooden wedges. This gives them the ability to slip behind the weather stripping more easily, with less chance of the weather stripping rolling under the wedge. The only problem is that if you are not careful with that sharp edge, you can also cut the weather stripping. Hard plastic wedges are also rather slippery and have a way of working their way out of the door as you work, which reduces your room to work.

Hard rubber wedges are pretty nice, but somewhat hard to come by these days. Most of the ones that I have used were made from old-fashioned chainsaw wedges that had been cut with a bandsaw. The problem is that modern chainsaw wedges are made from hard plastic instead of the dense rubber that they were made from 10 to 15 years ago.

Rubber wedges deform like the wooden wedges, and they are unlikely to break a window unless the user gets really carried away. The down side to rubber wedges is that they pick up and hold dirt and grit which could scratch the glass. This is especially the case if you dump your wedges into a tool box along with your other tools. Any oil that gets onto the wedge seems to turn the wedge into a dirt magnet. If you have any metal shavings in your tool box, these will also stick to the wedge and could easily scratch a window.

Regardless of which wedge you choose, the technique of using the wedge will be about the same. Your first job is to get the tip of the wedge positioned between the glass and the weather stripping. This can be as easy as using your fingernail to pull out the weather stripping, or require the use of a plastic shim. Personally, I prefer to use a plastic shim, as shown in photo 3, because most vehicles today use multi-layer weather stripping.

On a car equipped with multi-layer weather stripping, there are one or two more layers of weather stripping below the layer that you see. If you just pull out on the top layer and then shove your wedge into the door, you will wind up rolling the lower layer(s) of the weather stripping under your wedge (photo 4). If that happens, you are making your job harder than it needs to be. When the lower layer rolls, it effectively tightens the fit between the weather stripping and the glass. If you continue to push down on the wedge after the weather stripping rolls, you can even damage the weather stripping.

To deal with multi-layer weather stripping, I use a thin plastic shim inserted between the glass and all of the layers of the weather stripping. Then I slide my wedge into the door between the shim and the glass. The shim holds the weather stripping back out of the way of the wedge and eliminates the possibility of rolling the lower layers. You can buy a shim like the one shown in photo 3 or you can make your own from a variety of commonly available items. Hotel key cards also work well and they’re free if you travel much.

Another factor about wedging that is often overlooked is that you can generally open a wider gap at the center of the window than at the edges. There is simply more “give” the further you get away from the window tracks. That doesn’t mean that you can’t wedge near the edges of the glass; it just means that you have to be more careful when you do. I’ll often insert my wedges a few inches away from where I actually need to be with the tool and then angle the tool to reach what I’m after, just to give me more room to work with the tool. If you have to wedge near the window track, like on the late model GM trucks, be certain that you shim the weather stripping and that you don’t use too much pressure on the wedge.

Inflatable wedges (photo 5) are a poor substitute for a traditional wedge when opening a gap between the glass and the weather stripping. Most inflatable wedges are too limp to get them deep enough into the door to do a good job. If you don’t insert an inflatable wedge deep enough, it tends to just squirt out of the door as you inflate it. Even if you have a wedge with a stiffener inside, like the one shown at the left in photo 5 that can be easily inserted into the door, there is very little feedback about how much pressure you are applying as you inflate the wedge. It’s way too easy to put too much force on the glass with an inflatable wedge. Where inflatable wedges earn their keep is in wedging open a gap between the door and the door frame, so that you can insert a long reach tool.

There are basically two different types of door construction and they need to be treated differently. First the traditional type of door construction features a solid frame all the way around the window; that type of door is known as a sash-style door. Then we have doors where there is no frame around the top and rear edge of the glass; that type of door is known as a sashless door.

A sashless door requires special care and extremely gentle handling if you were to attempt to wedge it out at all.

Before using a long-reach tool on a car with sashless windows, consider the following factors before you begin:

- Does the car have indexing glass?

- Does the window have tempered glass or laminated glass?

- If the window is not indexing, how tight does it fit along the top edge?

- How far out will you have to wedge the glass in order for your tool to clear the trim?

Indexing glass is a relatively new system that uses the power window motor to force a tight seal between the top edge of the glass and the weather stripping. Before the door can be opened, the power window mechanism drops the window glass slightly, and after the door is closed, the same mechanism raises the glass and forces it tightly into the weather stripping or sometimes into a slot along the edge of the roof. If the window fits into a slot or the fit is very tight, the glass will probably break before you can open a gap wide enough to insert your tool.

All cars sold in the United States have been required to have “Safety Glass” for decades and almost all of them use tempered glass for the side windows. Windshields have traditionally used laminated glass and we all have seen what happens when a windshield gets a small crack or chip.

Recently, thanks to new manufacturing techniques, some cars started using laminated glass in the side windows. If you accidentally chip the edge of one of these windows, there will soon be a crack extending across the window.

Fortunately, any laminated window will be labeled like the one shown in photo 6. If you don’t see the word “laminated” in the stencil on the glass, you can assume that the glass is tempered. If you know that you are dealing with a laminated window, you will just have to be extra careful with the edges of the glass, or use a different method to unlock the vehicle.

Before indexing glass arrived on the scene, many manufacturers had found a surprisingly simple way to assure a tight fit along the top edge of the glass. On cars like the Mitsubishi Eclipse and Toyota Celica, the window track is built so that it pivots slightly as the door is opened. This allows the glass to sag a few degrees toward the car as the door is opened. As the door is closed, the upper portion of the glass contacts the weather stripping first, causing the top edge of the window to move up against the weather stripping along the top of the door opening. This drives the top edge of the glass firmly against the weather stripping and locks it in place until the door is reopened or the window is lowered.

If you attempt to wedge out a window built this way, you will find that it has very little “give.” Lubricating the upper edge of the glass with a silicone lubricant or dishwashing soap may help you open a larger gap, but you will still have to be careful.

Another factor that gets overlooked all too often is the trim around the outside of the window. Quite often there is a raised lip around the top and rear of sashless windows to guide water away from the door opening when the door is open. If you try to use a long-reach tool on these vehicles, you will have to pull the glass out far enough that your tool will not damage the trim. The Nissan 350Z (photo 7) is a perfect example of this and it is also equipped with indexing glass, which is why I would never attempt to use a long-reach tool on the 350Z.

I’ve seen the inflatable wedges promoted for use on sashless windows, and properly used, they work well for that purpose. But, the lack of feedback to the user coupled with the tremendous force that can be generated with an inflatable wedge make me very cautious when I use one on a sashless window. I use the absolute minimum amount of inflation and constantly watch and listen for signs of stress on the glass. I personally prefer the wedges that have a push-button valve because I can release the pressure very quickly if see or hear anything I don’t like. In fact, as I inflate the wedge, I keep my thumb positioned over the button just in case.

Sash style doors, on the other hand, have lots of strength and the window is well protected. I use inflatable wedges on sash-style doors almost casually. I still pay close attention to what the wedge is doing, and I still hold my thumb over the button on the valve, but I don’t worry about the glass.

When using an inflatable wedge on sash-style doors, the major concern is the trim. Honda vehicles are notorious for using plastic trim on both the door and the door pillars. If you are not careful, you can pop off or crack the plastic trim using nothing but an inflatable wedge. I don’t know what damaged the plastic trim on the car in photo 8, (I spotted this car in a parking lot and photographed it with my phone, ) but it could easily have been an inflatable wedge.

Unless they have plastic or aluminum trim, the construction of most sash-style doors will allow you to wedge them out a great deal before any damage is done. This is due to side-impact and roll-over safety standards that went into effect 10 years ago. Since then, car doors have been built with a great deal more “give” than in the past. The idea is that in a collision, the door should be able to flex so that it does not pop open. Using an inflatable wedge to insert a long-reach tool shouldn’t damage a modern vehicle as long as you use common sense.

Here are a few things to keep in mind when using an inflatable wedge on a sash-style door:

- Make sure that the center of the wedge is placed as close as possible to where you want the maximum pressure.

- If you are wedging the rear edge of the door, keep your wedge as high as possible, but still leave room to insert your tool.

- If you are wedging the top edge of the door, keep your wedge as far to the rear as possible, but leave room to insert your tool.

- Avoid putting pressure on the corner of the door.

- Open a large enough gap so that you can manipulate your tool without damaging the car.

- Use a protector for your tool to prevent scratching the paint.

- Beware of the weather stripping along the inside of the door.

- Never deflate the wedge until your tool is out of the door.

- Never open the door until you have deflated the wedge, unless it is absolutely necessary.

Most of the time, you’ll need to spread open the gap with some other tool like the levers that come with the Jiffy-Jak and similar tools. Always make sure that you spread out any force that you apply as much as possible with a base plate or something similar to protect the vehicle. At the same time, be cautious of plastic and aluminum trim. Just as when you’re wedging the base of the window, if you don’t have the wedge in far enough, it will tend to squirt out of the door as you inflate it.

The point of maximum leverage and the point where you can get the largest gap into the vehicle are at the top rear corner of the door. But that is not where you want to put your levers or your air wedge. That portion of the door is not the strongest portion and I have seen doors where the corner has simply folded over when pressure was applied. That type of damage will require a body shop for repair and it will cost you dearly. In addition, you want to insert your tool into the largest portion of the gap so that you have the maximum about of room to manipulate the tool without damaging the vehicle.

As a general rule, I position my inflatable wedge 2-4 inches below the corner of the door on the rear edge. On some occasions, I’ll place the wedge along the top edge of the door, again 2-4 inches from the corner, to leave room for inserting the tool. I prefer the rear edge of the door because it is generally the stronger area to work with.

When I’m using the Jiffy-Jak, I try to open a gap large enough for me to see clearly inside the car as I insert the tool. If I can’t get enough of a gap to see through, I’ll insert a plastic shim into the door to hold the weather stripping out of the way as I insert the tip of the tool. This is done in much the same way as I use a plastic shim to insert a wedge at the base of the window. This helps to prevent the most common type of damage associated with long-reach tools – torn weather stripping.

In my hands-on classes, a common mistakes is the user looking into the interior of the car through the window as he or she inserts the tool, rather than at the point where the tool is being inserted. Attempting to blindly shove the tool into the gap between the door and frame can result in the kind of damage shown in photo 9.

Most long-reach tools come with some kind of sleeve to protect the finish of the car from tool. A simple sleeve over your rod will prevent the rod from even touching the painted surfaces, which virtually eliminates the possibility of scratching. If you don’t have a sleeve for your tool, you can make one from a plastic pocket protector or plastic report cover from an office supply store.

Another silly sounding mistake is deflating the inflatable wedge as soon as the car is unlocked, but before removing the tool from the door. You just get in a hurry and don’t realize what you’re doing. The next thing you know, your rod is tightly pinned in the door and you may have scratched the paint or dinged the door or trim. I try to always remove the rod from the door, then deflate and remove the wedge and only then open the door. Opening the door while the wedge is inflated tends to surprise and alarm the customer. The door will usually pop open very enthusiastically, while your tool, wedge and any shims go flying in all directions.

The only time I intentionally open the door with the wedge inflated is when I’m working on a Toyota or Lexus that has an automatic relocking alarm system. late model Toyota and Lexus models use a cable operated system that will relock the door as fast as you can unlock it. But, on most of these vehicles made after 2003, and some made in 2002, pulling the inside door handle will override the lock mechanism. If you hold the handle out with your tool far enough, the relocking system will not be able to relock the car and you can reach down with your other hand and pull the outside door handle to actually open the door. If you inform your customer in advance of what is going to happen, there is generally no problem. But, if you simply let the door fly open and your tools go bouncing around without warning, they tend to think you don’t know what you’re doing.