When you’re doing the groundwork for your project, a good place to begin is determining the line voltage requirements. Does your equipment have line cords, wall-mounted transformers, or does it require hard-wiring to an electrical junction box?

Hardwiring of line voltage should be clearly stated to be performed “BY OTHERS” on your proposal or invoice to reduce the chance of a misunderstanding, or liability for your company.

You should clearly state the extent of the work you will perform and not assume the client will be thinking like you. Any ambiguity in your wording might become a ‘smoking gun” for some attorney in the event of an accident or fire. If you clearly state where your work stops and another trade will take over, it might diminish your culpability if it is determined a fire or accident was caused by an electrical problem. Make it clear that you and your technicians stay on the low voltage side; you are not charging for working on the line voltage, and consequently you take no responsibility for it.

Line cord and wall-mounted transformers require receptacles. You’ll need to find the circuit breakers which feed the receptacles you plan to use. If other equipment is currently plugged into the receptacle you want to use, then make sure that this device can be powered elsewhere, and your gear will not be unplugged when the person who originally made claim to that receptacle realizes he's been bumped. Or perhaps the cleaning crew uses that one for their vacuum cleaners. When you find the electrical panel(s) and circuit breaker(s), note their location and how many amps they are. Also determine how many other receptacles or other equipment are on the circuit breakers branch circuit, and of course, if your receptacle is on a wall switch.

Another point to consider is how many line cords and wall mount transformers you’ll have to find a home for. Many wall mount transformers are bulky and require planning to accommodate them properly.

We just were involved in a video project for a restaurant. One of the details we discussed with the client was where we would get power for the system. He indicated that the receptacle on the wall of his office, adjacent to the file cabinet upon which he wanted the monitor and DVR, was it. Of course, the receptacle turned out to be dead.

We advised the client to call an electrician and to obtain a UPS for the system to protect from power surges and to enable it to continue to operate in the event of a power outage.

Additionally the system had grown beyond its original single camera, DVR and monitor to a total of three cameras, three wall-mount transformers and two line cords. We had to lay in temporary extension cords and power strips, and finish after the client got the line voltage he had originally promised.

INTERCONNECTIONS (WIRING)

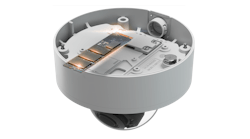

For our camera project, we needed to connect three Day/Night IR cameras back to the manager’s office. They were analog output cameras, meaning that we had to run RG-6 coaxial cable, as well as 12 Volts DC to each camera. Each camera was equipped with a dozen LEDs for viewing in the dark, and each required a surprising 500 ma. We decided to use Siamese cable. This cable was a coax bonded to a pair of #18 stranded for power. We also needed to be sure we had the BNC connectors we’d require to terminate the coax, as well as wire nuts for the splices the camera power would require. Special crimping tools are needed if you’re using certain types of BNC connectors.

Our project was in an old building which had seen its share of renovation over the years. There were concrete walls and dropped ceilings, along with a myriad of PVC pipes, electrical wires, vents and insulating material

Frequently getting the wiring specified and installed is a project all its own. For example, on another project, the card readers and intercom are going on a pedestal adjacent to a gate operator. It will take 1200 feet of cable to get from the gate area back to the main building. When you are dealing with numbers like these with low voltage access control and intercoms, research and planning are essential. Cable costs money. Every cable you add to the run costs. Then there is the labor to install the wire. Then there is the technical issues regarding signal integrity and voltage loss that will occur over 1200 feet.

After doing our homework, we arranged with the client that he would provide the wire and the labor to pull it. Our project involved a high power intercom, two proximity card readers, a visitor button, and an approach sensor. By carefully selecting our interfaces, we were able to reduce the cables to a twisted and shield 2X#18, and a single CAT5. The client was able to manage a portion of the project by using in-house labor or subcontractors with whom he already has ongoing projects, and we managed our own time without taking on work for which we don’t have the crew or proper equipment to efficiently perform.

INSTALLATION SITE

This refers to where you will situate the various system components. In our case this would be Camera 1 behind the bar (but not in view of the customers) to guard the liquor; Camera 2 in the kitchen to watch the kitchen door and Camera 3 in a storage room. The monitor and DVR would reside in the office, a cramped little area with a locked door and fire resistant file cabinet. The video gear was to sit on top.

LOCKING DEVICES, SENSORS

Most systems you install will also involve door closers and card readers, as was the case in our previous gate project, it is necessary for you to familiarize yourself with existing material and conditions on site, preferably BEFORE you quote the job. No matter how much you plan, there will be changes in a job. The goal is to try to keep all changes in the categories which will enable you to make more money as opposed to costing you money. If you are careless, even the simplest project can turn into quicksand.

If locking devices are part of your project, then the following issues need to be addressed:

Is the door on which the locking devices will be installed in good condition? How about the frame, and the hinges, and the door closer? Is the door “labeled,” meaning is it a fire-rated assembly? Is the door an emergency exit? (if there is an EXIT sign over it, then it probably is.)

Remember that safety is first and you cannot install any locks which will impede egress from the building. If the door is not working well right now, installing a lock on it will not heal the door, and eventually it will need to be dealt with, perhaps at your expense.

Example: I went out to a Home Center where the delayed egress exit device was not working. Although the door was physically latched, pressing the exit device opened the door. Well it sort of opened the door. What was going on was that they had repaved the parking lot, and the height of the asphalt was such that it impeded the swing of the door. I showed the manager. I called facilities and informed them. I told my dispatcher. It was decided by facilities that it would be more economical to simply replace the delayed egress unit rather than try to replace components one by one.

So a week or so later when the part came in, I swapped out the delayed egress unit. It now worked fine, but unless you were 6’2” and 200 lbs, it was difficult to open the door more than a couple of inches. Each time I opened it, it sounded like a coupe deville in a crusher.

So again I advised facilities, and showed the store manager on duty. When I wrote the invoice, I noted that the door was obstructed by the pavement and posed a life safety issue

That was three weeks ago. Yesterday we got a work order from facilities regarding this same door “was not opening properly.” Good grief.

When you are quoting your project, examine the door and bear in mind its condition and other issues which might affect the success of your installation. If you are going to be installing a strike in the frame, or running wire in the frame or in the door itself, try to anticipate problems with factors such as frame depth, pored concrete around the door frame, or intumescent material and/or bracing inside the door if cross drilling will be required.