In order to maintain key control, companies and institutions implement key systems and depend on lock manufacturers to control the issuance of key stock.

Lock manufacturers integrate new features into cylinders that are dependent on changes in the design of the key. When the key design is original, a patent is issued to protect the design, and the lock manufacturer is given exclusive rights to produce and furnish the key stock. This is the only effective means in which the lock manufacturers can control the issuance of key stock.

A patent is good for 17 years. When the patents expire, third parties are free to imitate the key stock and offer it without restrictions.

It usually takes several years for a key system to become popular. This shortens the protective interval in which the key stock can be protected.

To maximize the length in time in which key stock is protected, the lock manufacturers may wait to the last minute to introduce a new patentable design.

This article examines both past-and-future design changes that achieve patent-protective key stock while enhancing security.

Many companies offer patent-protective key stock. This article focuses on some of those companies that offer cylinders that can universally retrofit the different types of locking cylinders that companies and institutions already use. Consult your local locksmith wholesaler for their recommendations regarding high security lock manufacturers.

The companies that furnish the following key systems deliberately control the issuance of key stock so that end-users are assured that the ability to procure unauthorized keys is minimized.

All the lock manufacturers mentioned in this article concentrate on maintaining a supply of patent-protected key stock in as many common cylinder formats as possible. Just about every mechanical lock manufacturer is also developing electronic components if not complete systems.

As soon as a new patent is awarded to a lock manufacturer, that manufacturer continues the ongoing effort of developing the “next-generation” patent.

Locksmiths should be aware that any mechanical system they employ today should probably be changed out as patents expire.

It could be argued that the answer to continual replacement is to additionally support mechanical key systems with electronics.

Certainly there can be some electronic support for controlling access. However the cost of electronics, at least today, is more expensive than mechanical locks. A secondary factory is that electronics is still in an evolutionary stage as new products are constantly being developed and introduced.

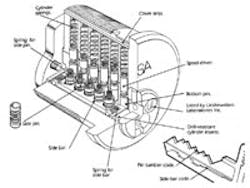

ASSA TWIN

These keys feature two sets of bittings.

The primary bitting set typically raises a standard set of six pins. Pin stacks may feature spool drivers.

The secondary bitting set is milled onto the side of the key and raises five special pins. Each pin features multiple “false” grooves, and one “true” groove. When all true grooves are aligned, the side bar is neutralized.

Usually the secondary bittings are static to guarantee exclusivity for a certain customer. When the customer orders key stock, the secondary bittings are pre-cut.

Hardened inserts are pressed into the face of the plug to resist drilling. One pin stack may be loaded with hardened top drivers to additionally resist drilling.

The Twin V-10 system was introduced as an upgrade to the ASSA Twin 6000 program. It included a coded sidebar, new profiles and patented key stock. It utilizes a standard cylinder plug profile (broaching). Various sidebar codes are used to create different keyways.

The UL437 version is called a “Twin Maximum.”

For more information, contact your local locksmith distributor or Assa Lock, phone 800-235-7482 or web site www.assalock.com.

ABLOY

The original design is based on rotating discs.

The shells of these cylinders are slotted for a round sidebar. Bittings are cut at the same depth but different angles on a round key. There can be up to 11 cuts corresponding to 11 discs. The discs are rotated with the movement of the key. At 90 degrees, if all the slots in the discs are aligned, the sidebar will retract.

There are seven possible cuts for each bitting, which computes to 1,970,000,000 possible combinations. There are no wasted combinations.

The face of the lock may feature different keyways requiring the keys to be milled appropriately.

The key is half-round in cross section with angled bittings along its length. Six bitting angles are possible from 0 (no cut) to 90 degrees, with a 90-degree cut leaving a quarter circle of key profile. The keyway may have wards requiring the key to be milled out to a different profile to restrict access.

Master keying is possible as each disc may have additional grooves cut into it.

The original rotating disc concept has been around for 90 years and has been improved on many times.

Today there are two high-security versions: DISKLOCK PRO and PROTEC.

DISLOCK PRO keys have angles cut on opposing sides and are milled to accommodate a special keyway. There are dimples cut near the head of the key to align pins in the front of the cylinder. Key blanks are highly restricted.

PROTEC features DISKLOCK PRO cylinders with extensive hardened fronts. Cylinders are all-metal and one-piece for durability. Keys are covered for a lifetime.

For more information, contact your local locksmith distributor or Abloy Door Security, phone 800-465-5761 or web site www.abloy.ca.

BILOCK

BiLock keys are essentially a piece of metal bent into the shape of a “U”. There are two sets of bittings, one on each side of the “U”. Each set of bittings raises a set of pins. When properly aligned, each set of pins allows a sidebar to be recessed, thus allowing the plug to be rotated.

Originally the flat key blade blank is cut top and bottom with unique bittings, and then bent into the “U”-shape. The blade is then pressed into a plastic colored key head.

Each bitting is a set of six cuts. There are four depths per cut. There is no safety factor so each bitting generates 4,096 different keys. Both bittings generate 16,777,216 different keys.

When masterkeyed, the top master key can access 6,561 pages with 81 change keys on each page or 531,441 change keys.

The latest addition to BiLock’s keying system is “New Generation.” “New Generation” employs a moving element in the key that engages a horizontal security rod built into the core. Without this engagement the plug cannot rotate. The addition of the moving element was patentable thus the keys can only be provided by BiLock.

BiLock cylinders can optionally be configured so that the plug can be removed from the shell with a special core-removal key. This feature allows plugs to be quickly swapped for fast rekey.

For more information, contact your local locksmith distributor or BiLock North America, phone 800-328-7030 or web site www.bilock.com.

CORBIN RUSSWIN PYRAMID

The Corbin Russwin Pyramid is a patented, high security lock system incorporating unique pin tumbler specifications and the secondary, “Pyramid” locking mechanism. The “Pyramid” locking mechanism is operated by a spring-loaded control pin located on the bottom of the key blade. This control pin engages a locking pin built into the cylinder.

Additionally, a blocking plate on the under side of the plug is depressed and deactivated when the key is fully inserted.

The cylinders feature seven chambers and pin tumblers are made from hardened stainless steel. The employment of the seventh pin provides a four-fold increase of change-key possibilities when compared with other six-pin systems.

Pyramid high security locks are available in a number of proprietary Corbin Russwin keyways. Corbin Russwin determines pyramid keyway assignments. Keyway decisions are based on system requirements and geographic location. To maintain a high level of security, Pyramid key sections cannot be integrated into existing Corbin Russwin systems. Keys can be duplicated or originated using standard key cutting equipment.

Pyramid keys are patent protected against unauthorized key duplication through June 2018. Corbin Russwin Pyramid locks are available as security and high security (UL437 listed) versions.

For more information, contact your local locksmith distributor or Corbin Russwin, phone 800-543-3658 or web site www.corbinrusswin.com.

KABA PEAKS

The original “Peaks Technology” patents focused on a smaller seventh pin located very near the face of the cylinder plug. This “locking” pin is designed to be raised by a detent or “peak” built into each Peak key. When the key is fully inserted, the “locking” pin is raised and if the proper bitting has aligned the rest of the pins to shear line, the plug will rotate.

The functionality of this engagement between the “peak” on the key and “locking” pin is what initially protected the key from being manufactured by others other than KABA.

KABA’s latest innovation is “Peaks Global.” The Peaks Global system incorporates three locking technologies and shear lines: a standard row of pins must be engaged; the seventh locking pin must be engaged by peaks on the top and bottom of the key; and discs must be engaged by “nodes” on each side of the key.

The innovation of discs that are aligned by the side “nodes,” also includes a blocking pins and filler caps in the positions where discs are not being employed.

The positioning and inclusion of discs is used to “personalize” key stock for individual customers.

Of course the innovation facilitates a separate type of patent-protected key stock that KABA can offer to its customers.

For more information, contact your local locksmith distributor or Kaba Ilco, phone 800-334-1381 or web site www.kaba-ilco.com.

MEDCO M3

The original locking technology employed by Medeco involves pins that must be lift to the proper height while being rotated to proper angles. When this occurs, a sidebar can be recessed into the plug and rotation is facilitated.

As the original patent was expiring, Medeco added the “Biaxial” locking technology. For each designated bottom pin, there were two versions, instead of one. There was a “Fore” bottom pin, or an “Aft” bottom pin. Where the pin would normally seat on the cut of the key was offset to the left or right. This required the key to also be cut either “Fore” or “Aft.”

Medeco now offers a third system based on this original design. It is called “Medeco3.”

Medeco3 keys are milled at the bottom of the right side to engage a “slider” built into the cylinder.

The slider blocks the sidebar. If the slider is not properly positioned, it will keep the sidebar from retracting into the cylinder even when all the pins are lifted and rotated to the proper position.

With the addition of the slider, there are now four different locking technologies in order to make the cylinder operable.

When patented key control is desired and physical pick and drill resistance is not needed, Medeco offers the KeyMark key control product line.

KeyMark’s patented locking technology relies on a multitude of keyways where the bottom portion of the keyway is set off to a prescribed angle. For each keyway there is key stock that matches the angle. One or more dimples in the proper key stock engage locking pins within the cylinder.

KeyMark’s forte is retrofitting with all types of lock cylinders, including small format or figure-eight interchangeable cores while being protected by patents.

For more information, contact your local locksmith distributor or Medeci High Security Locks, phone 800-675-7558 or web site www.medeco.com.

MUL-T-LOCK

The classic Mul-T-Lock system features telescopic “pin-within-a-pin” tumblers. A standard pin tumbler is one piece. Mul-T-Lock’s telescopic tumblers are composed of four parts: a bottom external pin, bored through in the center, an internal smaller pin that floats inside the external bottom pin; a spring to load the assembly and a driver that sits on top of the spring.

The height of the pin can be independently influenced by either the external or internal pins.

The patent-protected keys are oriented so that they enter the cylinder sideways and engage the pins with drilled dimples. There are two concentric dimples in each area of engagement: one to lift the external pin; the other to lift the internal pin.

Mul-T-Lock keys are handed with the grooves and cuts on one side of the blade. Each key contains a maximum of five double dimple cuts on each side of the blade. Cut numbers vary, depending upon the type of lock cylinders within a specific system.

Mul-T-Lock “Interactive” is a patented lock technology that introduces a set of locking pins to the cylinder and a set of movable pins to the key. The movable pins are pressed into the key and engage the locking pins in the cylinder when the key is fully inserted.

Keys that are not equipped with these movable pins cannot deactivate the locking pin built into the lock cylinder.

Cutting Mul-T-Lock keys requires the use of a special key machine to produce the double dimple cuts. This key machine originates keys using two spindle mounted cutters.

The next-generation development for Mul-T-Lock is the “Integrator.” It is comprised of a seven-pin configuration and includes “copy-protected” oval cuts on the key.

Mul-T-Lock cylinders are pick and drill resistant.

For more information, contact your local locksmith distributor or Mul-T-Lock USA, phone 800-562-3511 or web site www.mul-t-lockusa.com.

SARGENT

SARGENT introduced the Keso Security System in 1965. This high security lock mechanism was one of the first major improvements in pin tumbler lock construction. The Keso lock mechanism provided pick resistance, expanded master keying capabilities, proprietary keying and control over key duplication.

In 1995, SARGENT introduced the patented SARGENT Signature Series with multiple lock mechanisms that provide theft and vandal resistance. The Signature Series lock cylinders are available as UL437 High Security version. The Signature Series incorporates three pin tumbler lock mechanisms. In addition to operating as a pin tumbler lock mechanism, side pin lock mechanisms operate a blocking bar, one on each side of the plug.

The SARGENT Signature Series can be identified by a quill (feather) embossed into the plug faces and the keys. Signature Series lock cylinders are available as removable cores, mortise, key-in-lever, and rim lock cylinders. The Signature Series are laterally compatible with compatible SARGENT pin tumbler keyways. Signature Series lock cylinders retrofit into existing lock hardware.

The Signature lock cylinders are serviced the same way as standard pin tumbler locks. The side pins and blocking pins are secured into the plug.

Signature bittings can be cut on any standard key duplicating or code machine.

Signature lock and key patents will remain in affect until 2015.

Signature offers varying levels of key control regarding key stock issuance to locksmith, wholesalers, and end-users. Distribution of Signature lock cylinders and keys is controlled by the section and the dimple pattern.

For more information, contact your local locksmith distributor or SARGENT, phone 800-727-5477 or web site www.sargentlock.com.

SCHLAGE PRIMUS

The Primus system consists of two locking technologies: a standard row of six pin stacks; and a patented row of five “finger” pins. The finger pins interact with sidebar.

The patent-protected keys feature a secondary bitting milled along the right-bottom side of the key. This bitting interacts with the finger pins, lifting each to a level where a hole in the finger pin allows the sidebar to retract.

The pattern of this bitting is controlled and used to establish individual customers and groupings of customers in specific geographic areas.

Plugs can be optionally ordered for UL 437.Primus is set up to be especially flexible as it can co-exist and interface with existing standard Schlage systems.

For more information, contact your local locksmith distributor or Schlage, telephone 800-847-1864, web site www.schlage.com.

YALE

Patent-protected Yale Security Cylinders make use of two independent locking mechanisms to provide high security protection: a row of six or seven pin tumblers, with spool drivers; and a secondary set of five spring-loaded rotating discs that control a sidebar.

The patented keys have side millings that engage the rotating discs.

Yale Security Cylinders employ both the “GST” and “VYZ” families of surety keyways. In addition to the key restrictions, the Security Cylinders are available for those applications that require UL 437 pick and drill resistance. The cylinders have a hardened stainless steel cylinder head and rotating plug face.

The Yale Security Cylinders are available in three Security Levels. The base level, level 1 is the Registered Distributor. This level uses the GST family of keys. The side milling that controls the rotating discs is pre-cut from the factory. The rest of the key is left for the locksmith to cut, enabling the rekey of lock cylinders.

Level 2 is Registered to End User. This level uses the “GST” family of surety keyways. Lock cylinders are delivered to the end user from the factory. Cylinders are factory assembled and the factory furnishes finished keys. Extra keys are ordered and must be accompanied by the approval and signature of the end-user’s designee.

Level 3 Registered to End User (Restricted Keyways) is the highest level of security. Level three lock cylinders use the “VYZ” family of restricted keyways. These cylinders are sold by locksmith wholesalers for specific jobs. All other Level 2 requirements are in effect.

For more information, contact your local locksmith distributor or Yale, phone 800-438-1951, web site www.yalecommercial.com.