Two BILLION lock tumbler pins a year - that is the manufacturing capacity of the 120 Escomatic Swiss Screw Machines in the LAB manufacturing facility in Bristol, Conn. LAB produces more than 300 styles/shapes of pins; pins for lock manufacturers and locksmiths using brass, nickel silver and stainless steel. LAB has become the largest manufacturer of lock tumbler pins and kits servicing major lock manufacturers and security professionals worldwide.

LAB began in 1956 when Robert Labbe, a self-taught toolmaker had a vision of a high speed screw machine that could produce lock tumbler pins 20 times faster than any machine. Within one year, his high speed lock tumbler pin machine was producing pins. With this success, LAB was born.

The design of the machine was further refined and Robert Labbe produced eleven more machines while establishing his production company. Over the next two decades, LAB produced tumbler pins for many lock manufacturers. Two of the early customers were Eagle Lock and Lori Lock.

In the early 1970s, Robert Labbe decided to expand the product line by developing LAB brand aftermarket pinning kits. In 1974, LAB developed the single level No. 80 Pin Kit. The metal case No. 80 Pin Kit had 80 pin pockets. Seventy-nine of the pockets were filled with .005” increment bottom (.165” - .360”), master and top (.010” - .200”) pin lengths. There were also two large pockets for springs and tools.

This kit was advertised to have a “perfect seal as not to intermix”. To promote the No. 80 Pin Kit, Mr. Labbe went to locksmith trade shows and would literally throw his kits onto the floor to demonstrate his new leak-proof design keeping the tumbler pins within their pockets.

The lock pin tumbler industry was introduced to the .003” Universal Pin Kit by LAB in 1977. The .003” Universal No. U99 was designed originally with 99 pin pockets in a single-level metal case. With the slim design, the U99 kit was expanded to 124 pin pockets. The .003” Universal tumbler pins have become the standard for re-keying residential and light commercial locks.

There is a design difference between the LAB .003” and .005” bottom pins. The .005” bottom pins have a larger chamfer with a large flat at the top of the pin. The .003” bottom pins have a smaller chamfer with a slight rise ending with a smaller flat area at the top of the pin.

The larger chamfer on the top of the .005” bottom pins enable the plug to rotate even if the depth of cut in the key is not exact. A clicking sound and hesitation will probably be felt when the key with a too shallow cut is operating the lock cylinder. The cut that is not deep enough forces the bottom pin to stay above the shear line diameter.

This larger chamfer is required as the difference between a .005” pin and the original pin length may be as great as .004” of an inch. Whereas the .003” pin variation from the actual pin length can only be a maximum of .001”. This is why there is less likelihood of a .003” bottom pin raising above the shear line diameter.

To pin interchangeable core mechanisms, the Jumbo No. 36 Pin Kits were introduced for Best and Falcon using the .108” diameters pin tumblers.

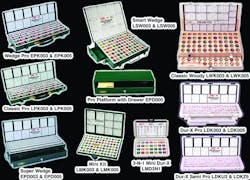

To provide alternatives to the metal cases, in the early 1990s LAB introduced wood pin kit cases. In the mid-1990s, the company introduced the resilient Dur-X (polyethylene) pin kit cases. The LAB Wedge Kits were introduced in 1994. The LAB Wedge Kits are designed on a 10 degree angle for easier viewing and obtaining pins.

In addition to expanding the types and styles of available pin kits, LAB has made improvements in the kits themselves. These improvements include Dual-View Pin Trays and Color Passport Pin Charts. On many LAB pin kits the pin lengths are printed on the top and the upper edge of each pin pocket. This enables easy pin type and length identification when standing or seated. The inside cover has always been used for the pin lengths chart(s). LAB improved the charts by printing not only the sizes for the manufacturer(s), but printing the sizes in the actual pin colors (red, green, brass, silver or purple).

LAB has further expanded their keying kit offerings by producing LAB brand pin kits that would accommodate pins and springs only for re-pinning of original factory conventional lock cylinders. These pinning kits contain springs, top and bottom pins that are the exact dimensions of the Original Equipment Manufacturers Pins. Original dimensions also include the bottom end of the bottom pins and the chamfer angles and shapes of the bottom pin’s top and the master and top pin’s end shapes. Best, Corbin, Kwikset, Master, SARGENT, Schlage, Weiser and Yale pins are pictured.

There are wide variations between lock manufacturers' pin shapes/styles. To complicate matters further, lock manufacturers also vary the diameter of different tumbler pin applications. Pin diameters can also change by the country of origin for the lock manufacturer. Several examples of different diameter pins include:

• Conventional lock cylinders use .115” diameter pins

• Medeco uses .135” diameter pins

• Interchangeable Core uses .108” diameter pins (please do not refer to these pins as IC Core- ICore)

• Many tubular locks use .077” diameter pins

• Master Padlocks use .0925” diameter pins

• Yale Peanut (small diameter cylinders) use .095” diameter pins

• Many mogul lock cylinders use .0156” diameter pins

Included in this article are close-up illustrations of a number of different lock manufacturer’s bottom pins. The shape of the bottom pin’s tips can be very different. These shapes include pointed tip, rounded end or double ended. There are even variations from lock manufacturer to manufacturer within the pointed tip shape tumbler pin. The tip dimensions are designed to meet or exceed the specifications of the lock manufacturers. LAB produces tumbler pins and pin kits for over 30 lock manufacturers worldwide.

Today, LAB tumbler pins are manufactured on precision Swiss Machines that have been modified by LAB to increase accuracy. As an example, pin tolerances for the Universal Kits are + .001” for the bottom pins. The machines are capable of tolerances of .0025" on a consistent basis.

The LAB Universal Pin Kits are available in .003” and .005” increments. In addition to be available in different styles of cases, some of the kits contain additional pins, etc. For example, Smart Wedges contain new tangle resistant springs, three spool pin sizes (common used by Schlage .165” and Kwikset .160” and .180”) and Schlage “T” top pins and “T” pin springs for the “F” series lock cylinders.

An interesting note regarding Universal Pin Kits are the .003” increment kits are outselling the .005” kits by seven out of every ten kits sold, whereas the replacement pins .005 increments are outselling the .003 increments by 60 to 40 percent.

Over the years, LAB has made additions and improvements to their product lines as a direct result of input from locksmiths. For more information, contact your local locksmith distributor or LAB, 700 Emmett St., Bristol, CT 06010. Telephone: 860-589-6037. Fax: 860-583-7838. Web site: www.labpins.com

Related

Related

Door Hardware

Master Lock Co.

Nov. 27, 2007

Biometric access control

Schlage, An Allegion Brand

Nov. 27, 2007

Alarms, exit

Yale Commercial Solutions

Nov. 27, 2007